Multiple-chamber type double steel plate concrete combined shear wall

A combined shear wall and concrete technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of loss of bearing capacity, excessive rigidity, and large temperature stress of the structure, so as to enhance the seismic performance, and facilitate the adjustment and reduction of stiffness. The effect of temperature stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

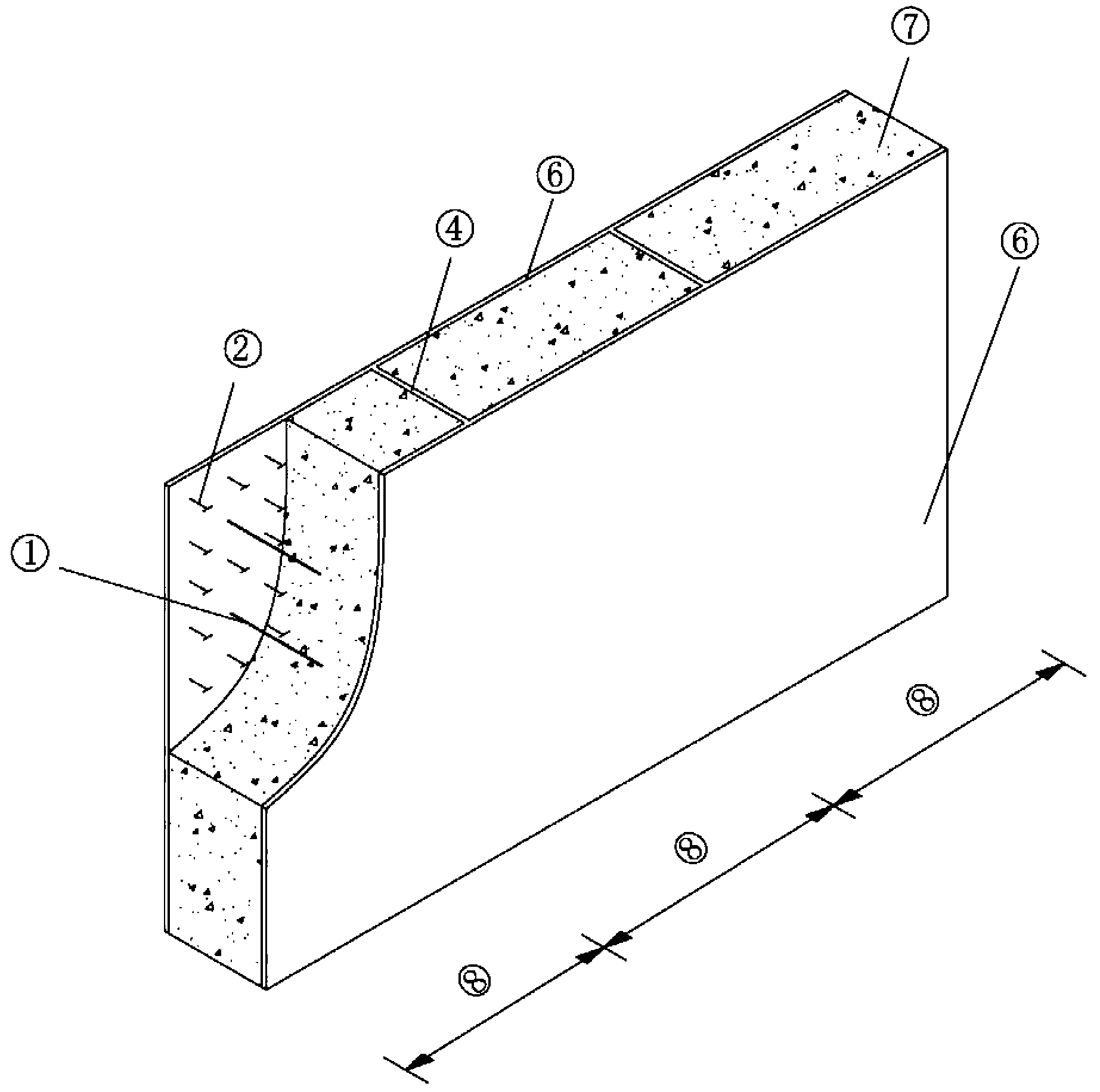

[0030] figure 1 It is the axonometric drawing of the traditional double steel plate concrete composite shear wall.

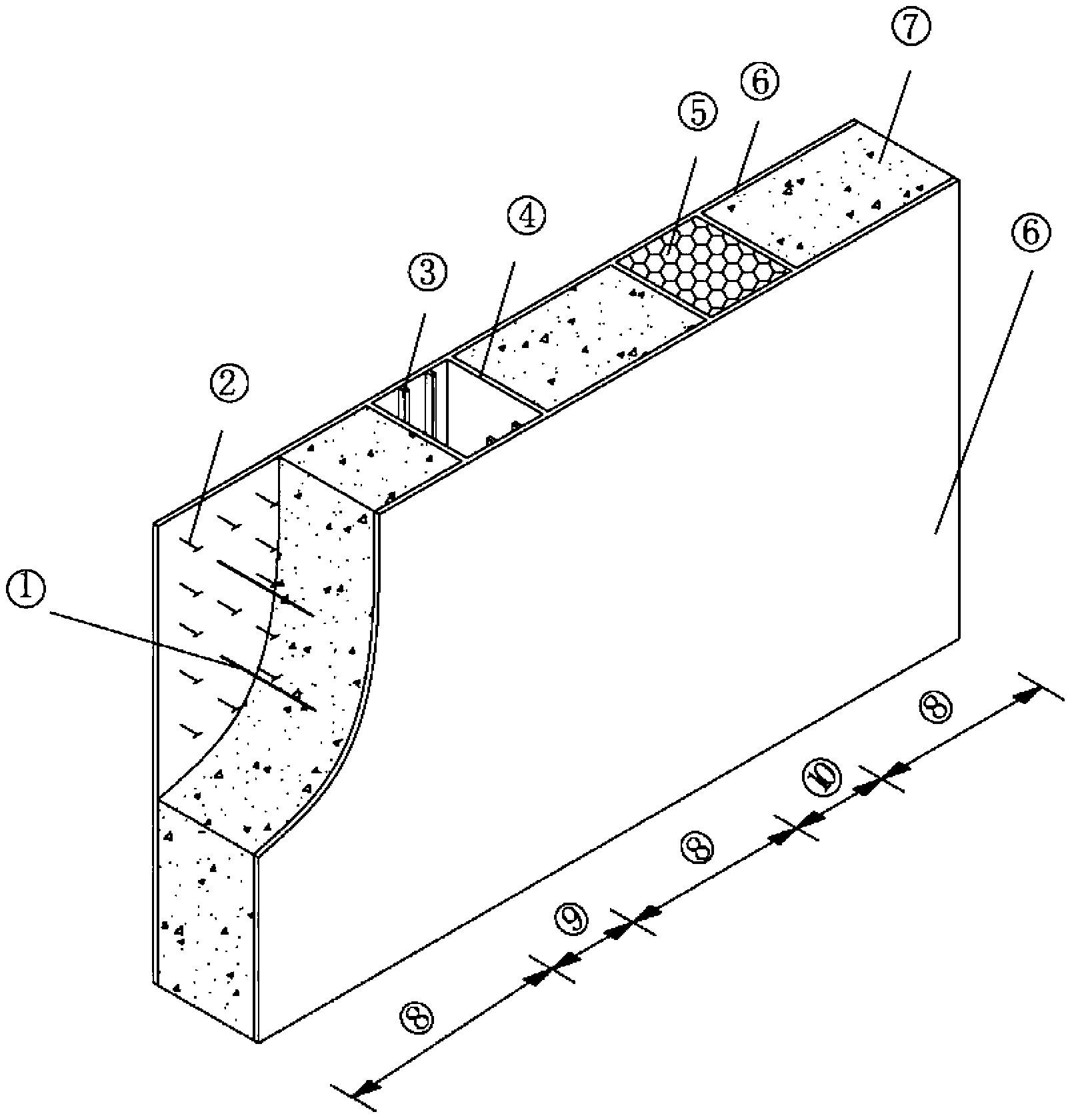

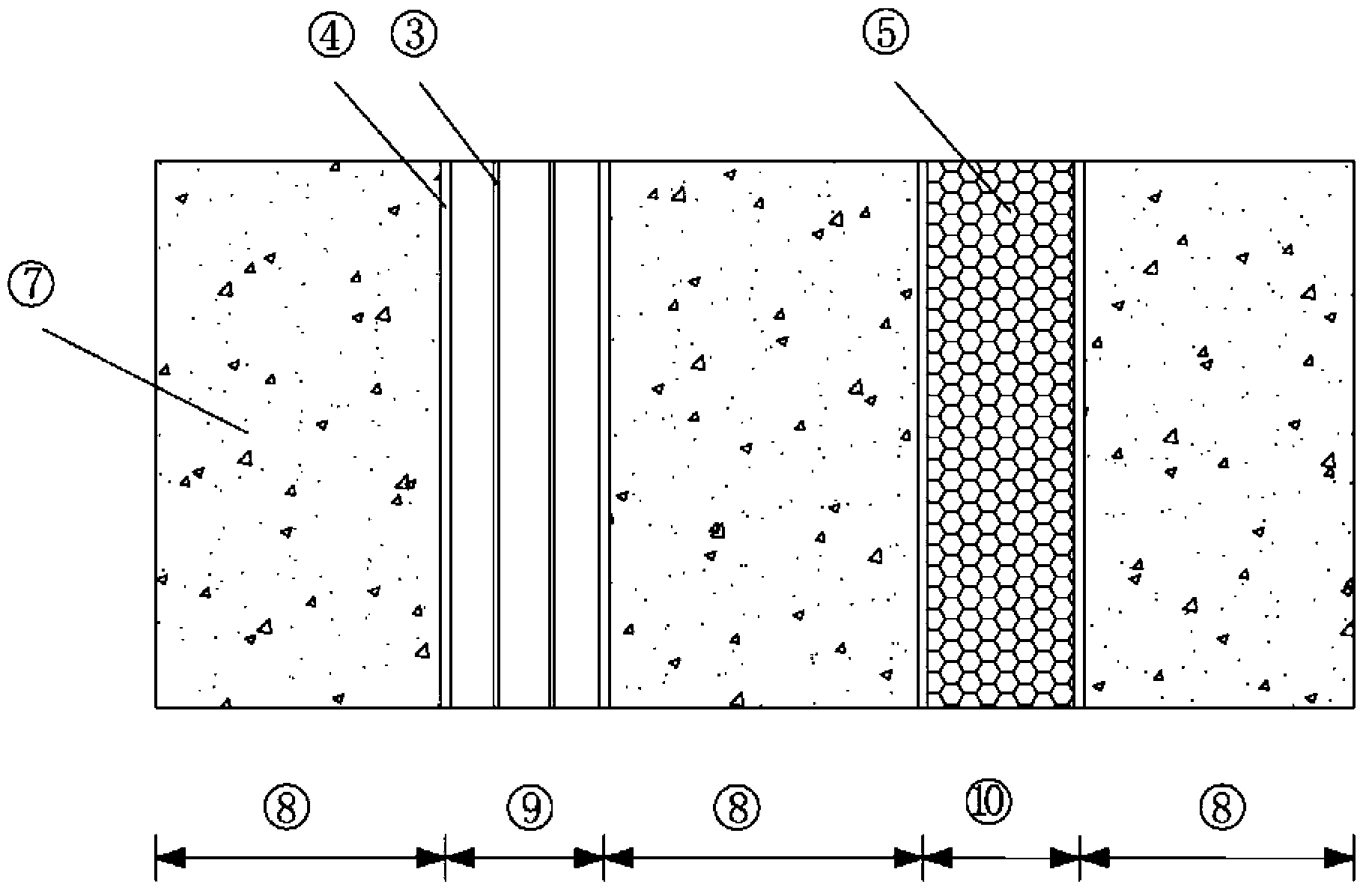

[0031] See figure 2 , image 3 , the present invention is a multi-chamber double steel plate concrete composite shear wall, which is composed of two steel plates 6 on the surface of the wall and plain concrete 7 inside the wall, between which there are studs 2 welded on the steel plates, The tension bars 1 and the vertical partitions 4 are connected to ensure the cooperative work between the two. And use the vertical partition 4 to divide the wall space between the two steel plates into compartments, and then pour concrete in a part of the compartments to form a concrete compartment 8, and the other part of the compartments is kept empty and filled with porous energy-consuming materials such as aluminum foam. The material 5 forms empty chambers 9 and energy-dissipating material-filled chambers 10 , thereby forming alternate distributions of concrete chambers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com