Detachable prefabricated steel-concrete combined beam structure and manufacturing technique thereof

A prefabricated concrete slab, prefabricated assembly technology, applied in the direction of structural elements, long-strip structural components for load-bearing, building components, etc., can solve problems such as insufficient shear capacity of steel-concrete composite beams, and avoid premature The effect of cracking, overcoming concrete corrosion, and convenient replacement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

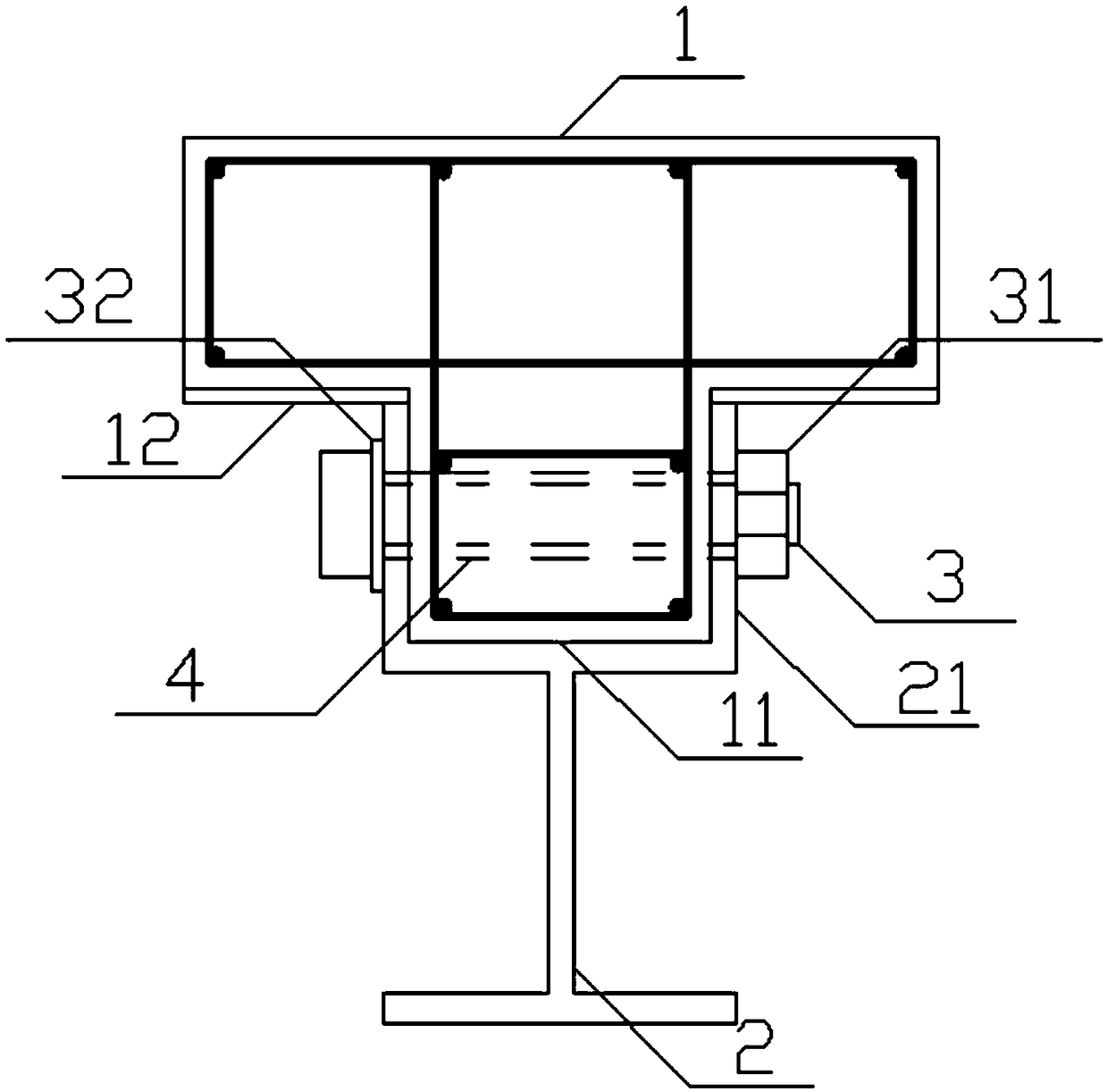

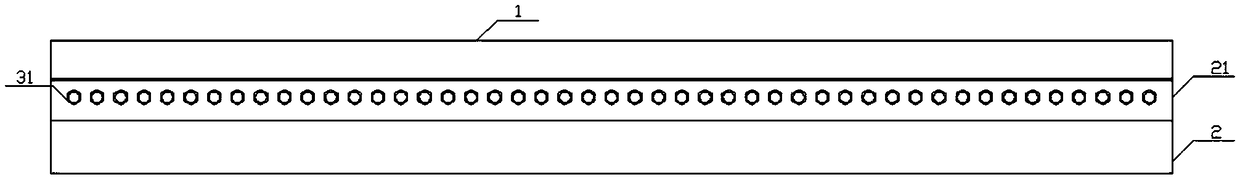

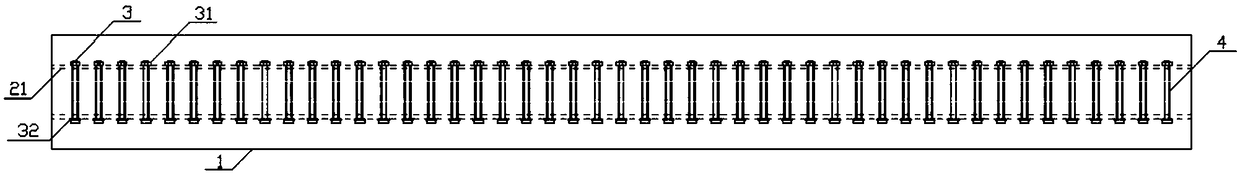

[0046] Embodiment 1: refer to Figure 1 to Figure 6, a detachable prefabricated steel-concrete composite beam structure, including concrete slab 1, concrete slab support 11, waterproof layer 12, steel beam 2, channel steel upper flange 21, high-strength bolt 3, hexagonal nut 31 , Spacer 32, sleeve 4. The sleeve 4 is arranged in the connecting hole 5 of the concrete slab support 11 . A waterproof layer 12 is arranged on the lower flanges on both sides of the concrete slab 1 . The connecting hole 5 of the precast concrete slab 1 is aligned and spliced with the reserved hole 6 of the channel steel upper flange 21 of the steel beam 2 . The connection between the steel beam and the concrete slab is realized by high-strength bolts 3 . The spacer 32 is arranged at the high-strength bolt 3 . Another place uses hex nut 31 to tighten the bolt and finish fixing.

[0047] refer to Figure 4 , make a reserved hole 6 on the channel-type upper flange 21, and arrange the steel beam 2 ...

Embodiment 2

[0049] Embodiment 2 A manufacturing process of a detachable prefabricated steel-concrete composite beam structure, the steps are as follows: the first step, according to the engineering requirements, the steel beam, the channel steel upper flange of the steel beam and the described Precast concrete slab contact surfaces are treated for dedusting and derusting;

[0050] The second step is to arrange the steel beams according to the direction required by the project;

[0051] The third step is to arrange the sleeve in the connecting hole of the supporting part of the concrete slab;

[0052] The fourth step is to arrange a waterproof layer on the lower flanges on both sides of the concrete slab;

[0053] The fifth step is aligning the connecting hole of the precast concrete slab with the reserved hole of the channel steel upper flange of the steel beam;

[0054] The sixth step is to realize the connection between the steel beam and the concrete slab through high-strength bolts;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com