Raking prop structure used for natural draft cooling tower and construction method thereof

A technology of natural ventilation and oblique pillars, which is applied in the direction of pillars, columns, pier columns, etc., can solve the problems of shortening the construction period, project cost, complex scaffolding support system, and high construction cost, so as to meet the requirements of strength and earthquake resistance, easy maintenance, The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

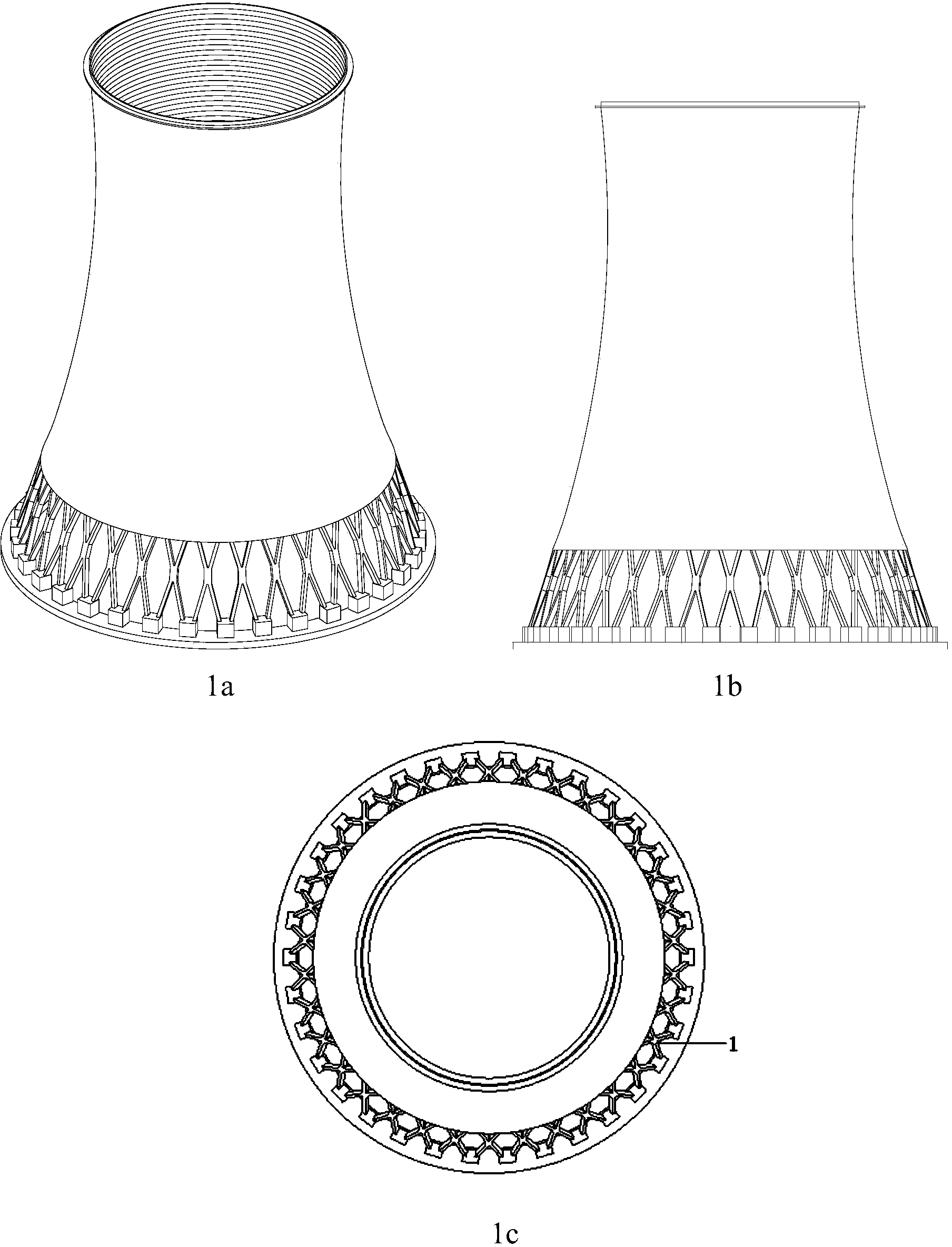

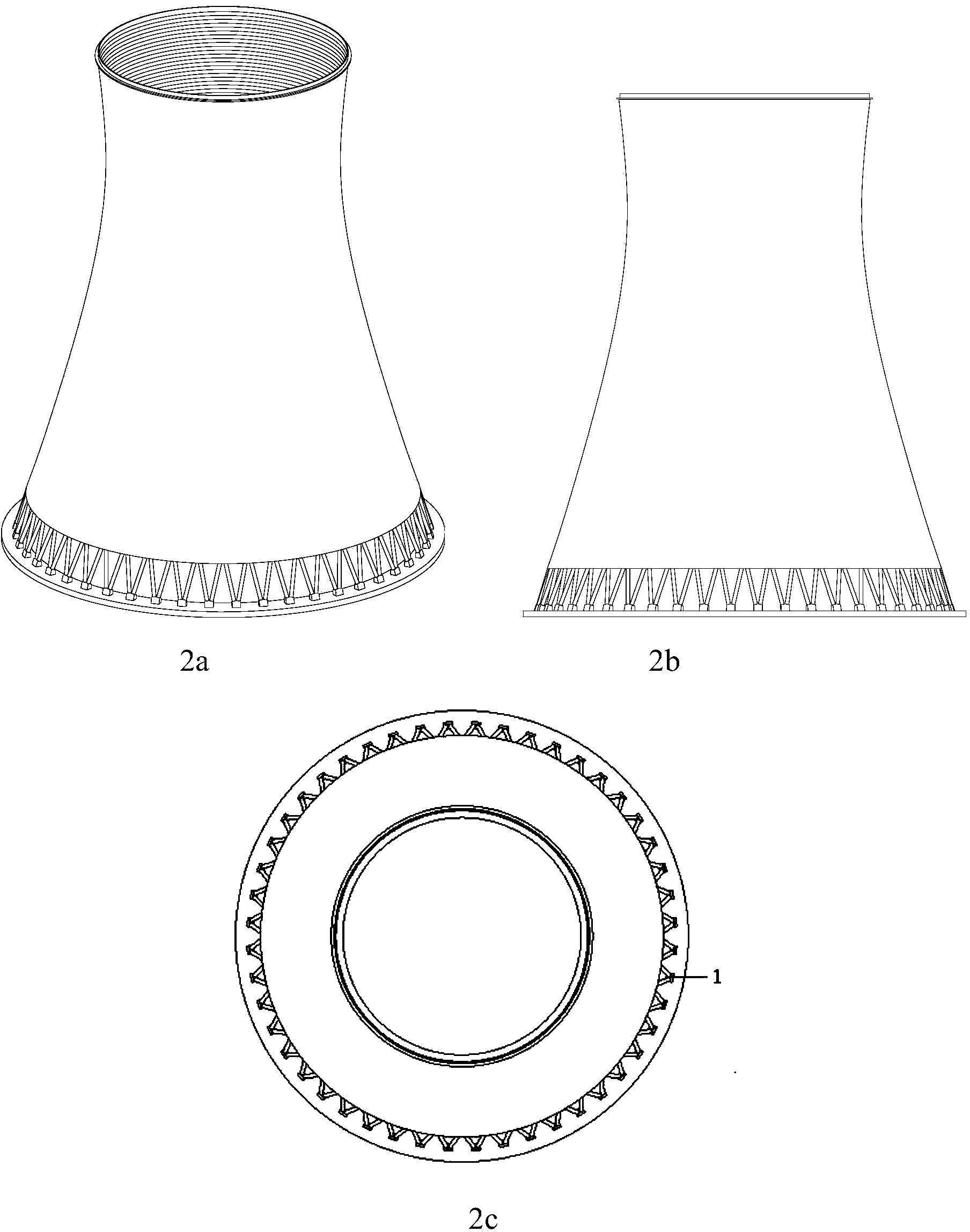

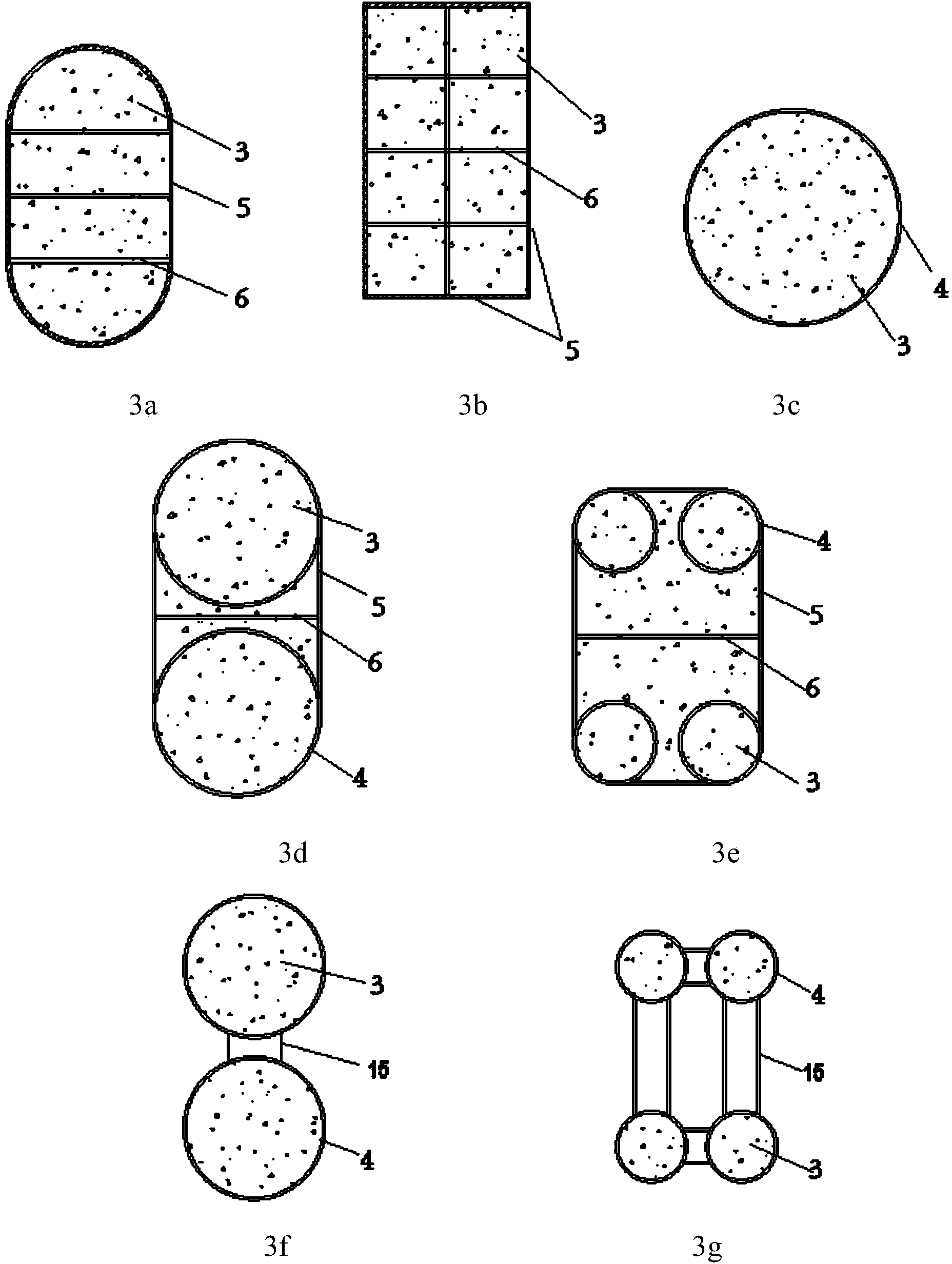

[0035] see figure 1 , 2 , is an oblique strut structure for a natural draft cooling tower of the present invention, the upper part of the oblique strut structure is connected to the tower tube, and the lower part is connected to the ring base through a buttress. The tower tube is a reinforced concrete shell structure; the ring base is a reinforced concrete ring plate structure; the buttress is a reinforced concrete block structure. The pillar structure includes V-shaped and X-shaped oblique pillars, and a steel pipe-concrete composite structure ring beam made in sections at the top of the pillar. The oblique pillar structure consists of a plurality of pillar frames 1 interconnected to form a ring structure. The pillar frame 1 is a steel pipe-concrete composite structure composed of steel pipes and concrete filled in the steel pipes; the pill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com