Combined reinforcement continuous wall and construction method thereof

A construction method and reinforcement technology, which are applied in excavation, sheet pile wall, foundation structure engineering, etc., can solve the problems of high requirements for construction personnel, large pollution of external mud, and high cost of mud discharge, and improve construction conditions and construction. impact, superior structural ductility performance, and the effect of reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

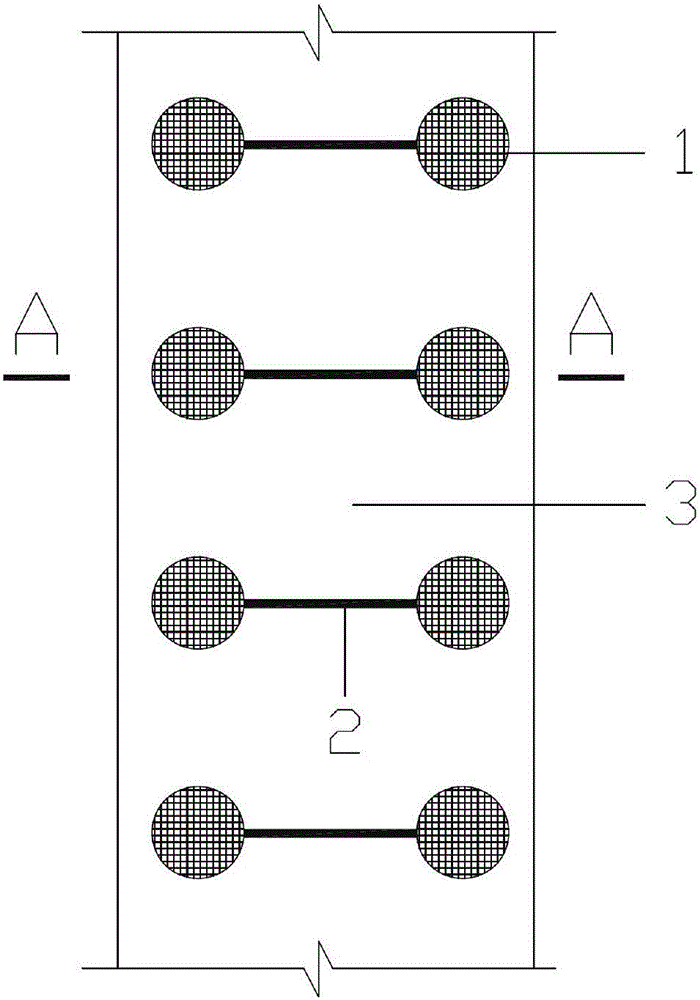

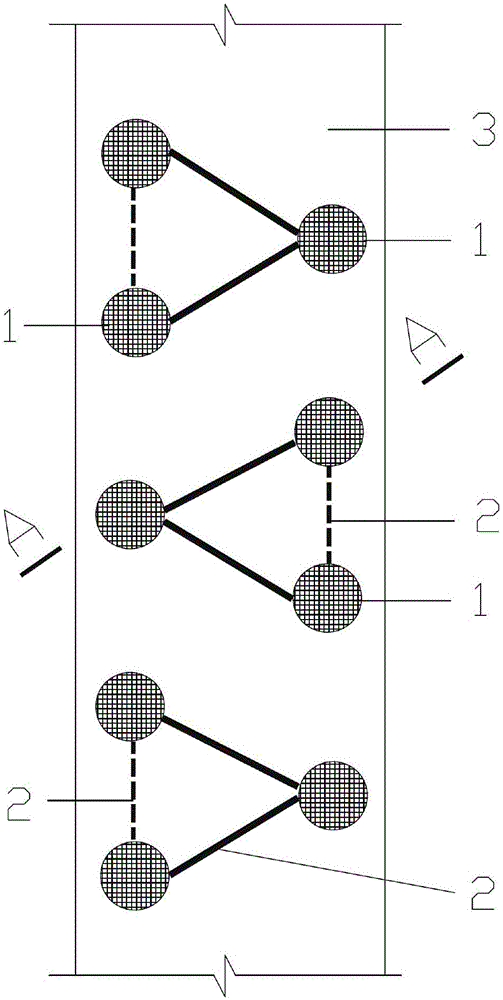

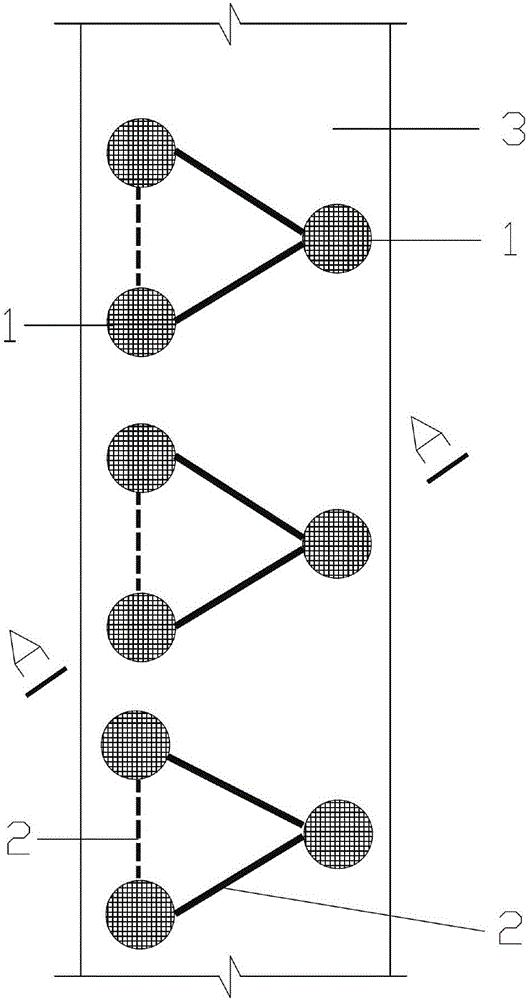

[0077] Step 1: (see Figure 1 to Figure 17 shown) as described above to make composite reinforcements.

[0078] The second step: make cement and soil external auxiliary materials according to the above construction.

[0079] Step 3: Quickly insert the combined reinforcement to the predetermined position before the initial setting of the cement and soil.

[0080] Step 4: Fill in the inner filler according to the construction method mentioned above, and the body crown can be removed and reused after the outer auxiliary material is condensed.

[0081] Step 5: After the external auxiliary material and the internal filling material are condensed and reach the set age, the continuous wall of the combined reinforcement is formed.

Embodiment 2

[0083] The first step: with embodiment 1.

[0084] The second step: make lime soil external accessories according to the above construction.

[0085] Step 3: Before the initial setting of the lime-soil slurry, quickly insert the combined reinforcement to the predetermined position.

[0086] The fourth step: with embodiment 1.

[0087] Step 5: Same as Example 1.

Embodiment 3

[0089] The first step: with embodiment 1.

[0090] The second step: make lime soil external accessories according to the above construction.

[0091] Step 3: before the initial setting of the lime-soil slurry, quickly insert the combined reinforcement to the predetermined position, and mix sand and stone into the lime-soil slurry to form the external auxiliary material of composite clay.

[0092] The fourth step: with embodiment 1.

[0093] Step 5: Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com