Method for constructing steel column and column head sizing steel model of profile steel

A construction method, technology of steel column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

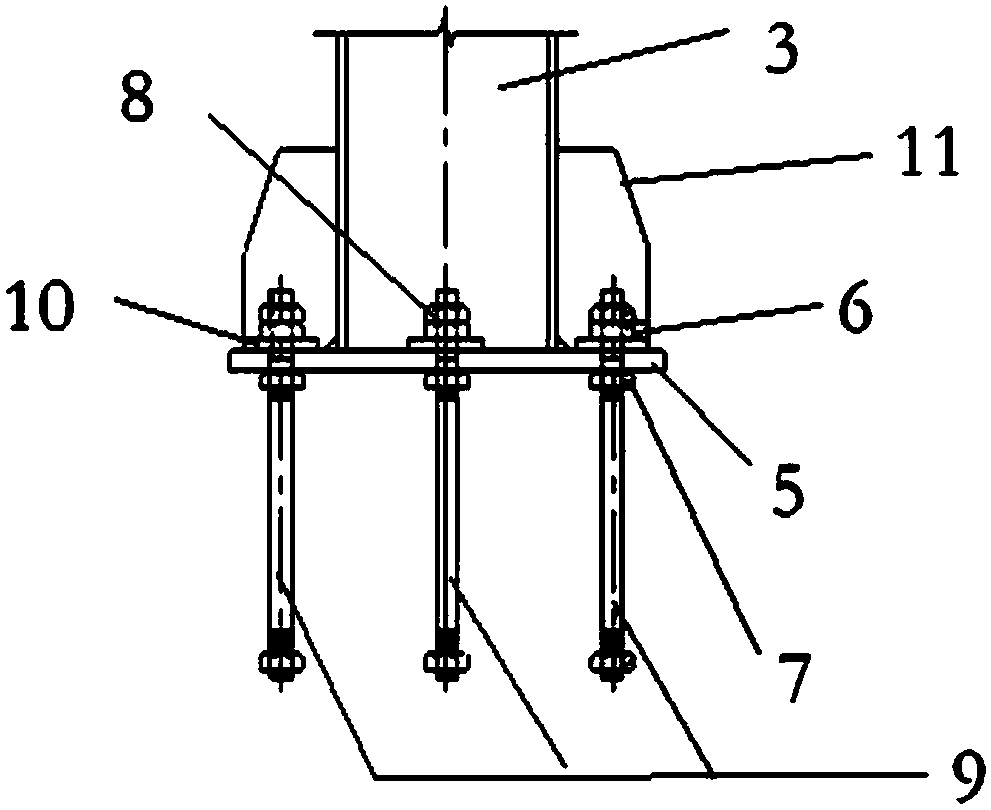

[0036] (1) Multiple sets of anchor bolts 9 are pre-embedded along the horizontal and vertical directions according to the set position on the cap foundation. Each set of anchor bolts 9 is composed of multiple anchor bolts. Adjusting nut 7;

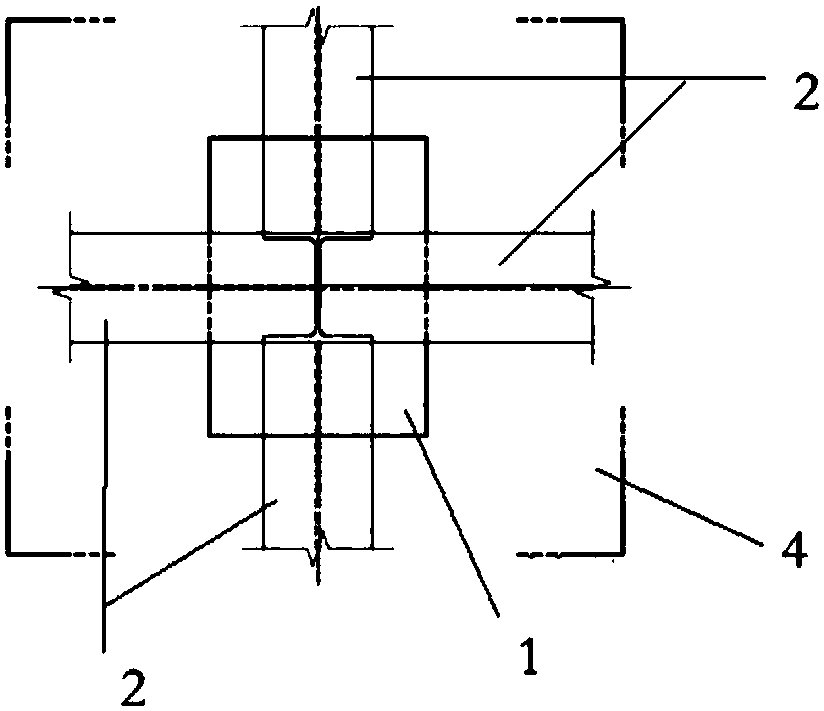

[0037] (2) Use a tower crane to hoist the shaped steel column and make the base plate 5 of the shaped steel column supported on the adjusting nuts 7 of a set of anchor bolts 9 correspondingly arranged, then insert a backing plate 10 on each anchor bolt and Screw in a fastening nut 6 and a stop nut 8 in turn, and then adjust the elevation of the adjustment nuts on each group of anchor bolts so that the elevation error of all backing plates is controlled within 1.0 mm. A column foot rib 11 is fixed between the bottom and the column foot bottom plate 5, and a column cap shaped steel mold 1 is connected with a bolt on the column head of the shaped steel column. A steel beam installation joint 2 is installed in the horizontal direction;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com