Bogie auxiliary framework of railway wagon and production technology thereof

A technology for railway freight cars and production processes, which is applied to bogies, railway car body parts, manufacturing tools, etc., can solve the problems of difficulty in guaranteeing casting and machining, large dimensions of sub-frames, and difficulty in overall manufacturing, and reduces mechanical The effect of processing difficulty, low processing production efficiency and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

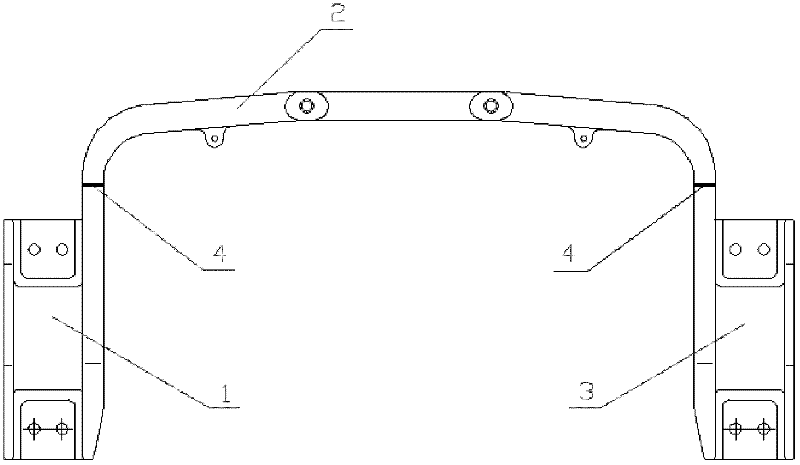

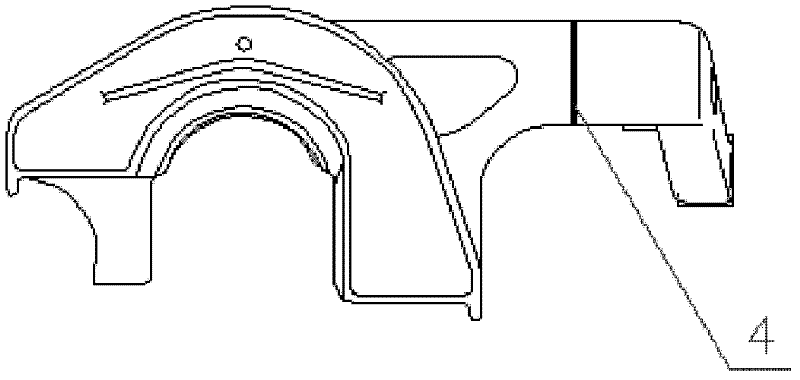

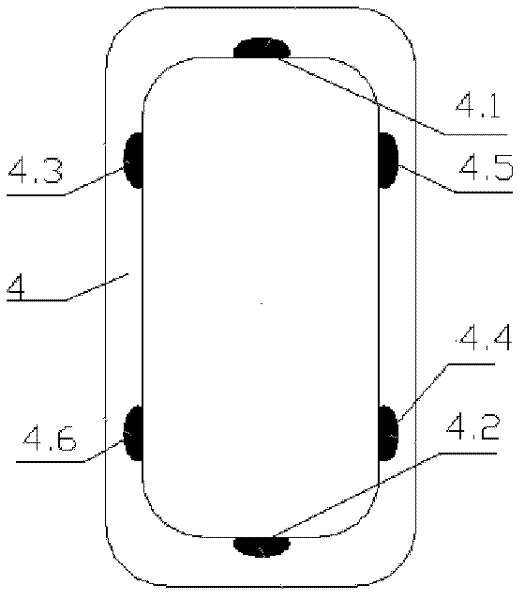

[0048] combine Figure 1 to Figure 11 .

[0049] The sub-frame of the railway freight car bogie and its production process of the present invention adopt segmental casting, separate processing, then assembly and welding to form, and finally process key characteristic dimensions, which can effectively ensure the quality requirements of each part of the sub-frame and smoothly realize the manufacturing process of the sub-frame .

[0050] Such as Figure 10 as shown, Figure 10 It is the cloud map of the stress amplitude of the U-shaped sub-frame structure, and the test of the tension rod force ± 42KN is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com