Double sand core positioning device and method

A positioning device and sand core technology, which is applied in the field of sand mold casting, can solve problems such as difficult operation, waste of labor, scrapping of castings, etc., and achieve the effect of ensuring the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

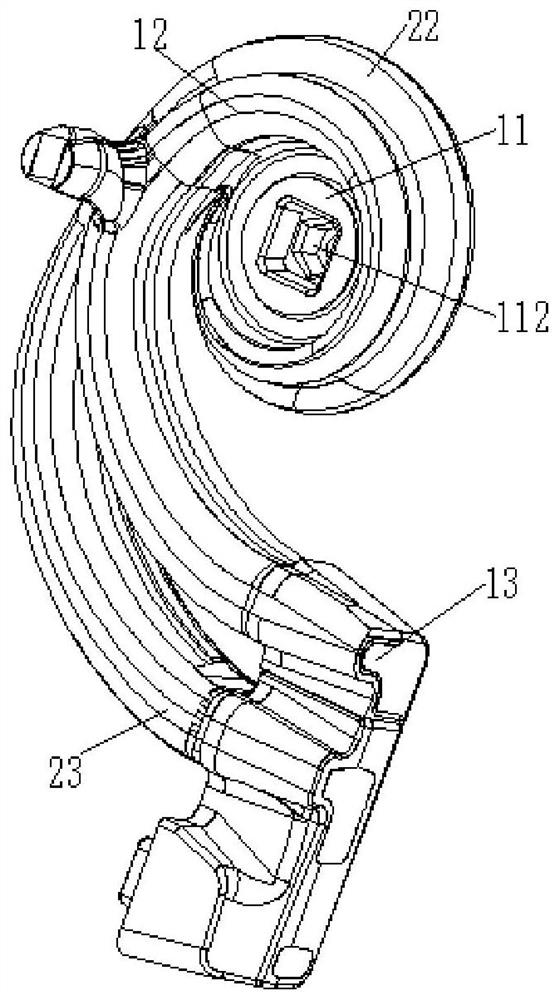

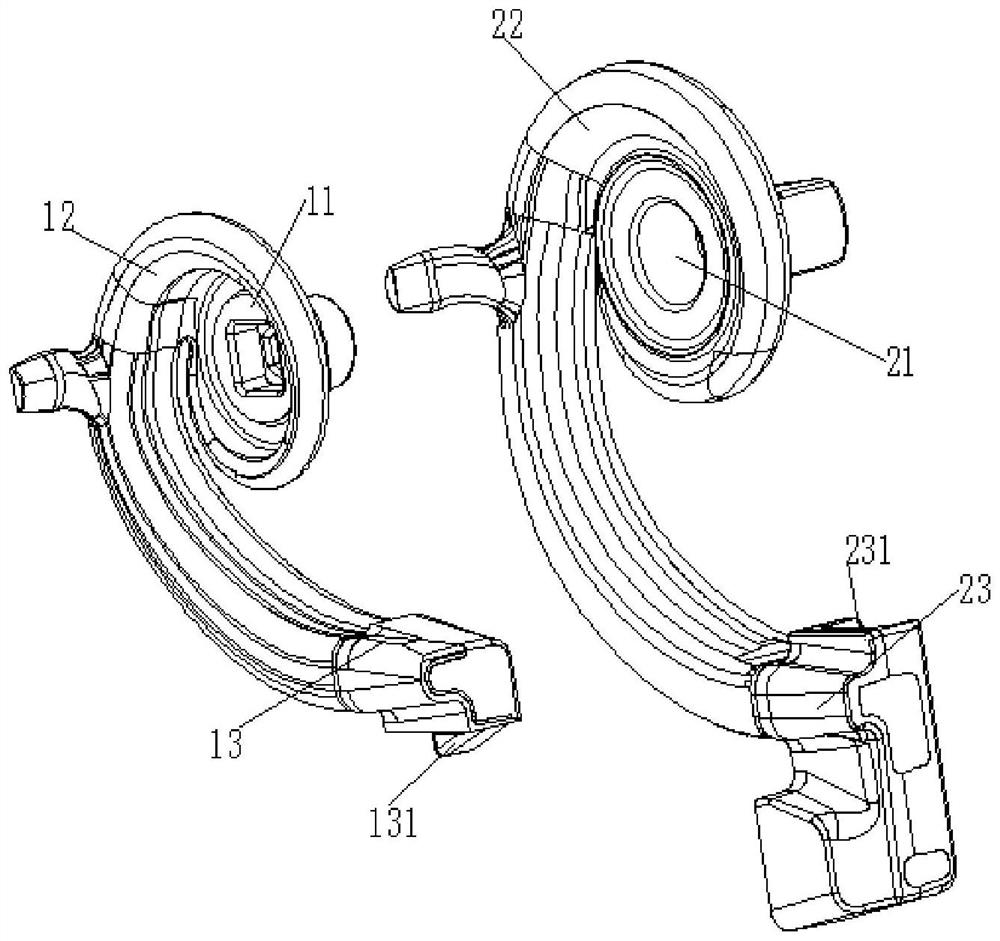

[0034] Such as figure 1 - Figure 4 As shown, the embodiment of the present invention provides a double sand core positioning device, including a connecting piece and a first sand core 1 and a second sand core 2 that abut against each other; the first sand core 1 includes a first forming part 12 and a first sand core. The connecting part 11, the second sand core 2 includes a second forming part 22 and a second connecting part 21, the first connecting part 11 and the second connecting part 21 can be fixedly connected by a connecting piece, so that the first forming part 12 and the second forming part Sections 22 remain relatively fixed and form a gap therebetween for forming a bulkhead.

[0035] The double sand core positioning device provided by the embodiment of the present invention includes a connecting piece, a first sand core 1 and a second sand core 2, wherein the first sand core 1 and the second sand core 2 can abut against each other and be fixed in the mold cavity O...

Embodiment 2

[0057] The embodiment of the present invention provides a double sand core positioning method, which is designed by using the above-mentioned double sand core positioning device, and includes the following steps in turn:

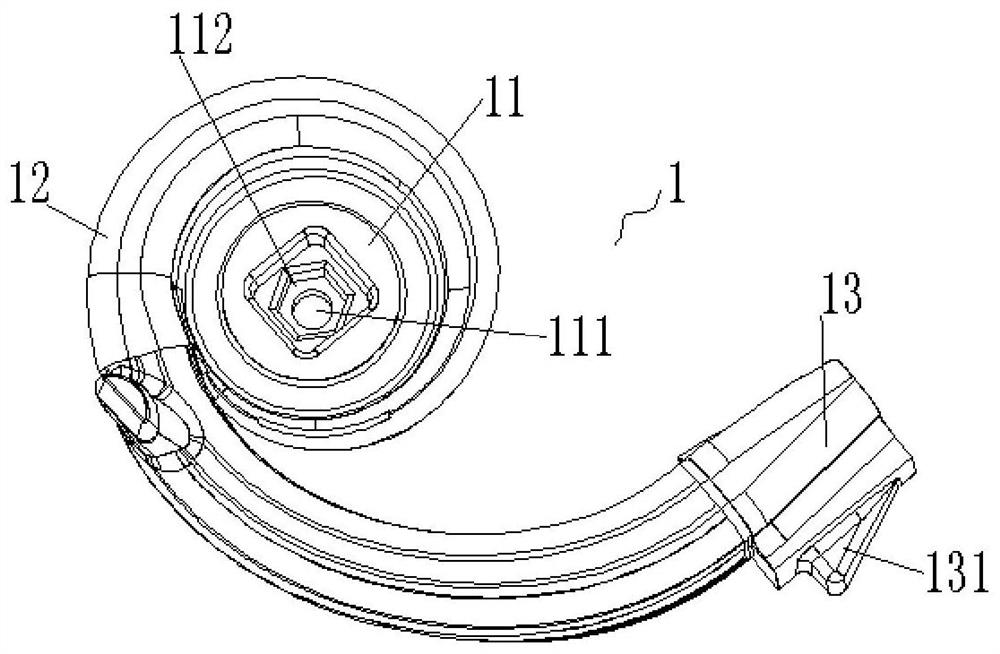

[0058] S1: Combine the first sand core 1 and the second sand core 2 so that the central axis of the first through hole 111 and the central axis of the second through hole 211 are on the same straight line;

[0059] S2: passing the bolts through the first through hole 111 and the second through hole 211 respectively, and clamping the nut of the bolt in the first groove 112 at the end of the first through hole 111;

[0060] S3: Use a wrench to tighten and fix the nut and the bolt protruding from the end of the second through hole 211. At this time, the ends of the nut and the bolt are all located in the second groove 212 at the end of the first through hole 111;

[0061] S4: filling the first groove 112 and the second groove 212 with molding sand and pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com