Cooling device for overcoming shrinkage porosity defect of casting and cooling method of vertical casting

A cooling device and cooling method technology, applied in safety devices, casting equipment, manufacturing tools, etc., can solve problems such as lack of replenishment of casting parts, affecting casting quality, shrinkage, etc., to ensure casting quality, optimize casting process, The effect of good casting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

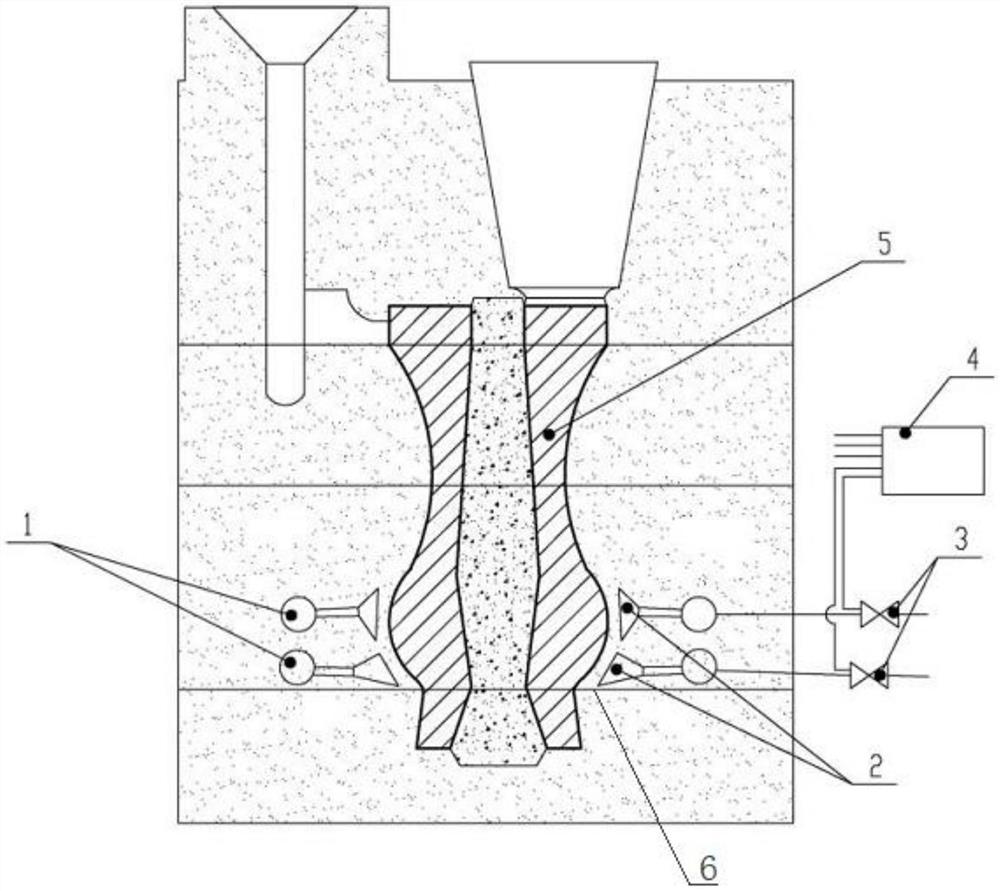

[0017] The controllable cooling device is arranged on the mold used for casting, and cooperates with the original mold to complete the processing of the casting 5 with vertical structure and local volume expansion, such as figure 1 shown. The cooling device includes one or more layers of cooling delivery pipes 1 (two layers are provided in this example), and the cooling delivery pipes 1 can be pre-embedded inside the mold or fixed outside the mold. The cooling delivery pipe 1 is provided with a blowing nozzle 2, and the blowing nozzle 2 is provided with a corresponding control switch 3, the control switch 3 is a control valve, and the control valve is a manual control valve or an automatic control valve, and the automatic control valve is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com