Cast imbedding lifting lug casting pipe

A lifting lug and casting technology, which is used in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as uneven end faces of standard parts, poor appearance quality of castings, and increased cleaning workload, so as to achieve low production costs. , Easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

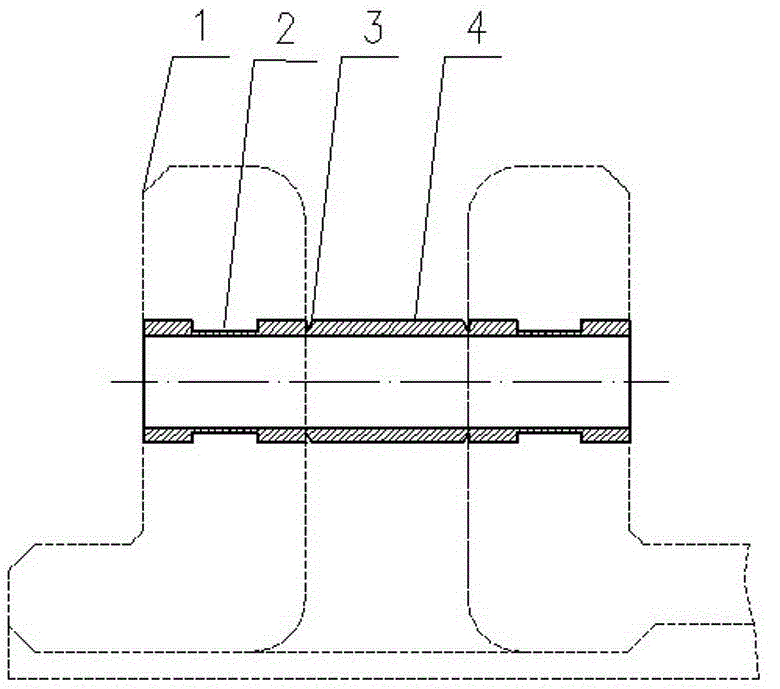

[0012] The present invention as figure 1 shown.

[0013] Casting-in-cast lifting lug casting tube, including casting body 1, casting lug casting tube 2 is cast in casting body 1, lifting lug casting tube 2 is provided with a groove 3 on the outer wall of casting body 2, and the depth of groove 3 is 0.5 ~5mm, angle 0°~60°.

[0014] The contact surface between the inner surface of the groove 3 and the contact surface of the casting body 1 is two parallel surfaces.

[0015] The inner surface of the angle between the groove 3 and the contact surface of the casting body 1 are two parallel surfaces, that is, the lifting lug cast into the tube 2 after knocking is a plane on the surface of the casting body 1, and there is no trace left after knocking .

[0016] The grooves of the above-mentioned easy-to-clean lug cast-in tubes are made according to the installation size of different lugs. Put the above-mentioned easy-to-clean lug cast-in tubes into the lug holes of the prepared pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com