Construction method for installing wire pipe and wire box on the wall

A construction method and a technology of wiring pipes, which are applied in the direction of cable installation, cable installation devices, electrical components, etc., can solve the problems of slow construction progress, different sizes of tanks, and easy cracking, etc., to reduce environmental pollution, surface Smooth and beautiful, reduce the effect of common quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

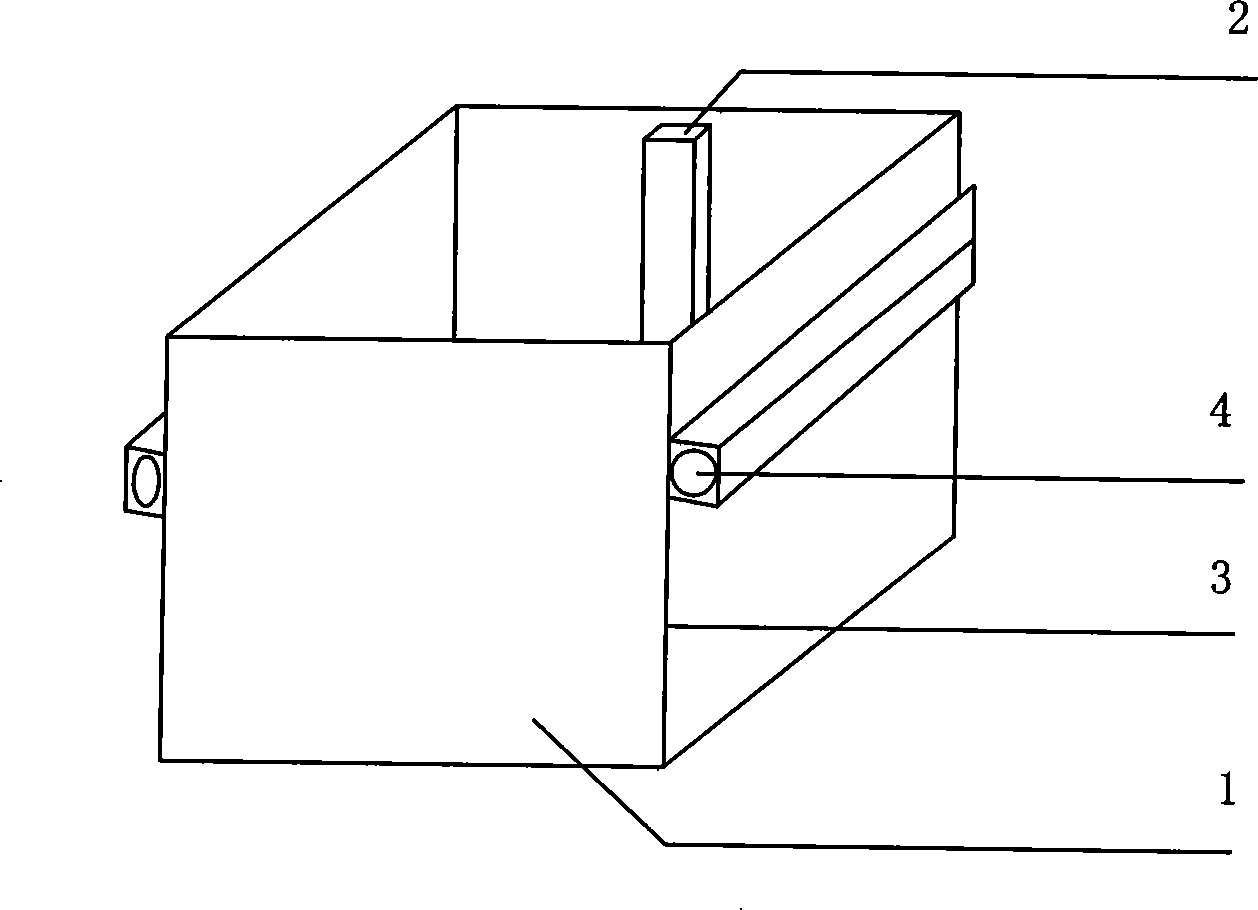

[0044] This embodiment is a construction method for wiring pipes and wire boxes on a shear wall, and the wire boxes used are as follows: figure 1 As shown, its main structure includes a housing 1 with a connecting groove 2, one side of the housing 1 is open, figure 1 The middle opening faces upwards, and its specification is 86mm×86mm×80mm (that is, the depth of the shell 1 is 80mm), and a horizontal through hole 3 of Φ10mm is respectively provided on the outer side of the upper and lower sides of the shell 1. Install it in place, and then carry out the civil construction of the wall. The main steps are as follows:

[0045] (1) Construction preparation: mainly including materials such as wire boxes and welding machines for construction;

[0046] (2), line pipe construction: the line pipe 6 is installed in place;

[0047] (3), wire box installation: wire box 5 is installed in place;

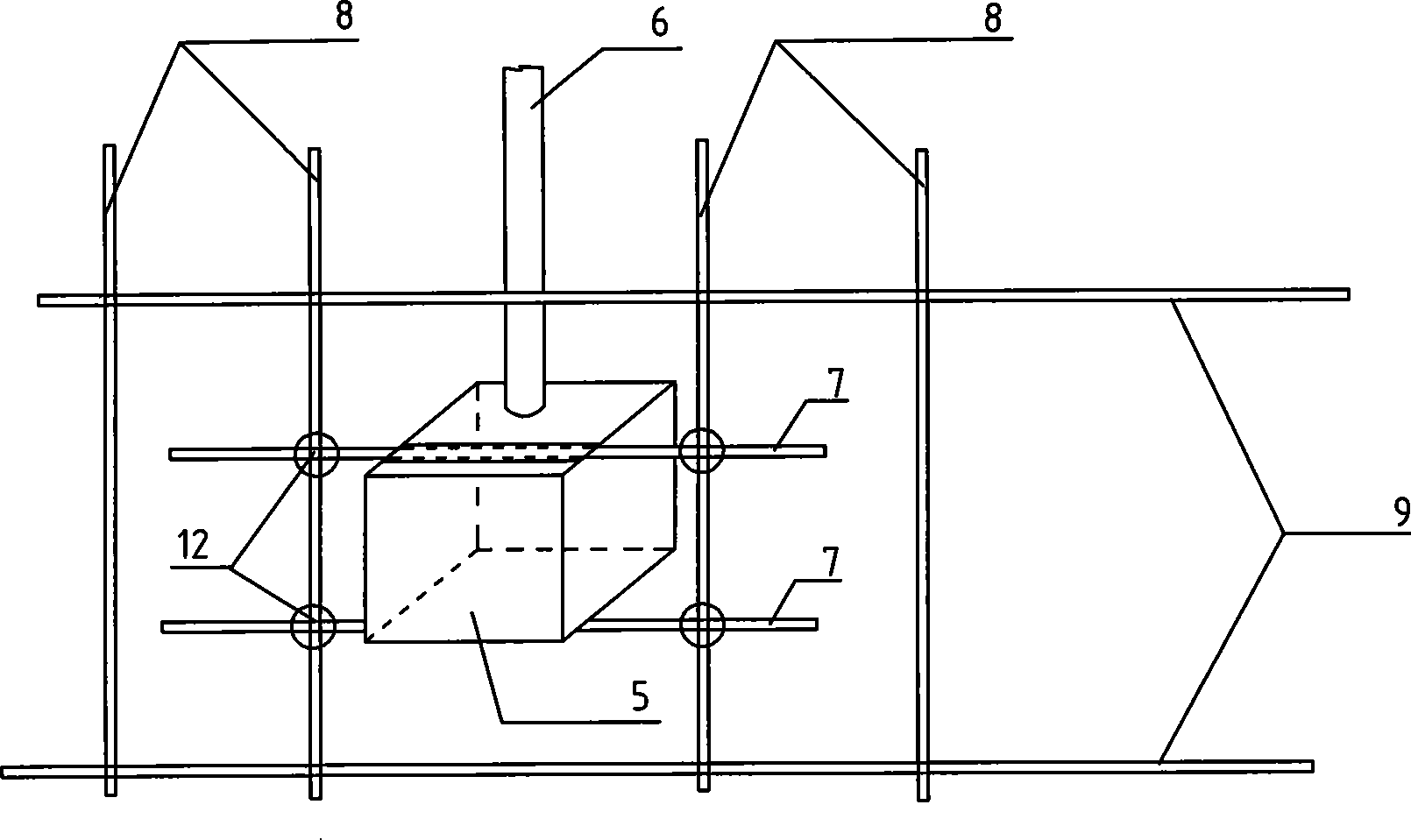

[0048] (4), wire box fixed: such as image 3 As shown, the horizontal through hole 3 on th...

Embodiment 2

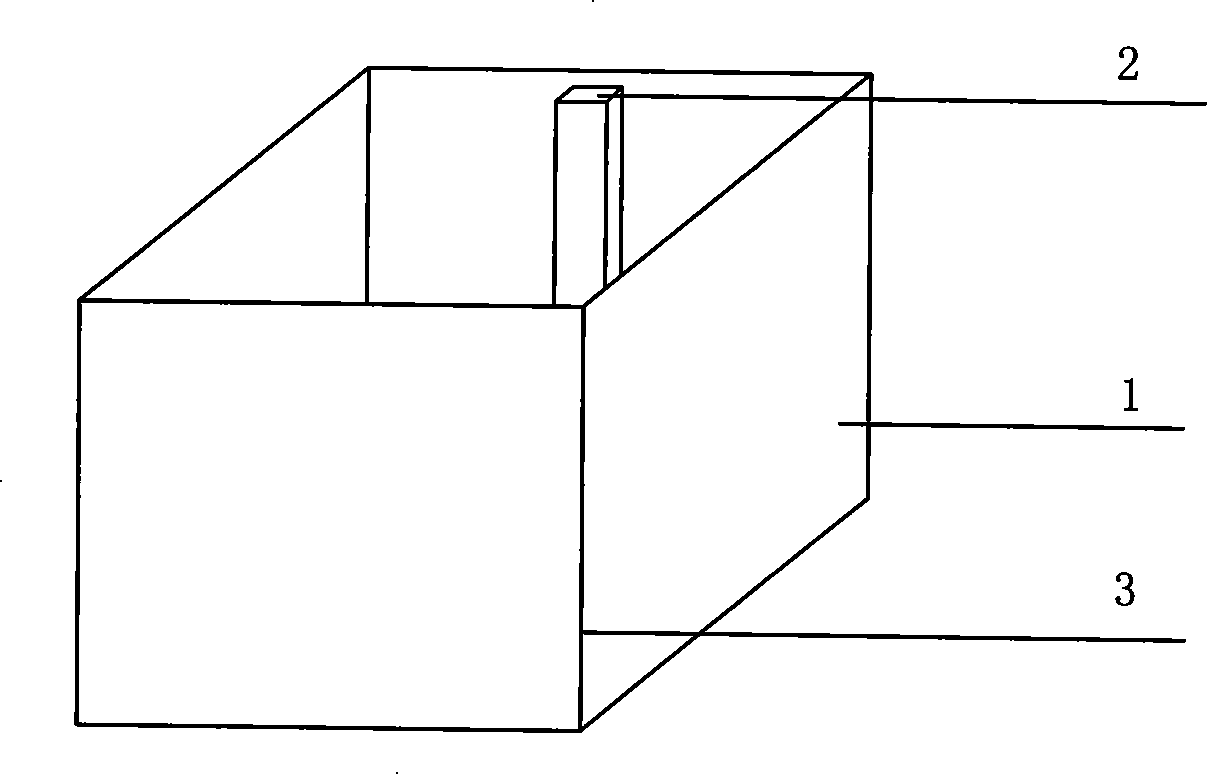

[0052] This embodiment is a construction method for wiring pipes and wire boxes on a brick wall, and the wire boxes adopted are as follows: figure 2 As shown, its main structure includes a housing 1 with a connecting groove 2, one side of the housing 1 is open, figure 2 The middle opening faces upwards, and its specification is 86mm×86mm×80mm (that is, the depth of shell 1 is 80mm). During construction, first install the wire box in place, and then carry out the civil construction of the wall. The main steps are as follows:

[0053] (1) Construction preparation: specifically including the calculation of the number of bricks to be cut, the preparation of cutting machines, etc.;

[0054] (2), brick concentrated drilling and laying grooves: according to the brick requirement of line pipe 6, wire box 5 installation part, gather some bricks and carry out cutting groove or drilling, prepare the brick 11 that cuts into groove; Groove The size of the (hole) is determined according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com