Suspension type embedded part and hole reserved template fixing method

A technology of reserved holes and embedded parts, which is used in the field of reserved hole template fixing and suspended embedded parts, can solve the problems of complex construction process, inaccurate positioning, and difficult to fix the settings of embedded parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

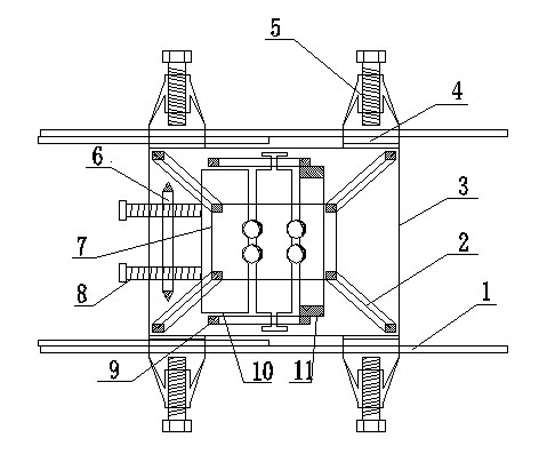

[0026] Referring to the accompanying drawings, the fixing method of suspended embedded parts and reserved hole formwork is composed of fixing frame connection, stabilization process and embedded part or reserved hole formwork and fixing frame connecting process.

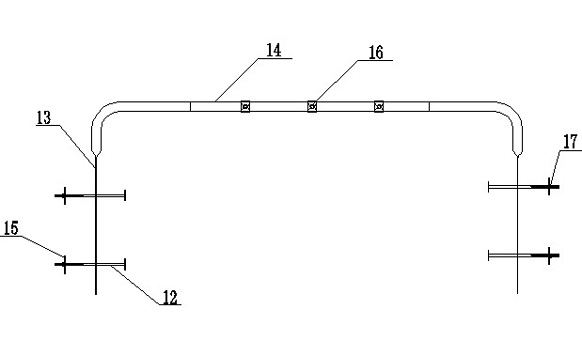

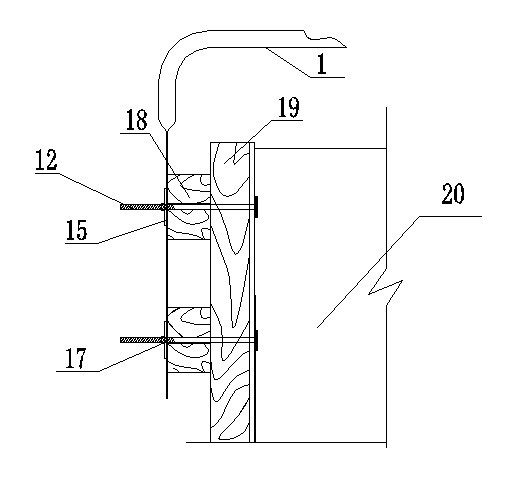

[0027] In the process of connecting and stabilizing the fixed frame, the fixed frame is first designed and installed, and the fixed frame is composed of two parallel monolithic frames 1 and an intermediate platform assembly (see figure 1 ), the monolithic rack 1 is relatively connected by two L-shaped monolithic racks, the L-shaped monolithic rack includes a terminal flat section 13 and a horizontal connecting section 14, and the terminal flat section 13 is provided with a screw hole, and the monolithic rack 1 spans Determined according to the length or width of the base, after splicing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com