3D printing reinforced concrete structure integrated implementing device and method thereof

A reinforced concrete, 3D printing technology, applied in building construction, building material processing, construction and other directions, can solve the problems of difficult material filling, rapid construction contrary to additive manufacturing, etc., to improve labor efficiency, simple structure, Flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

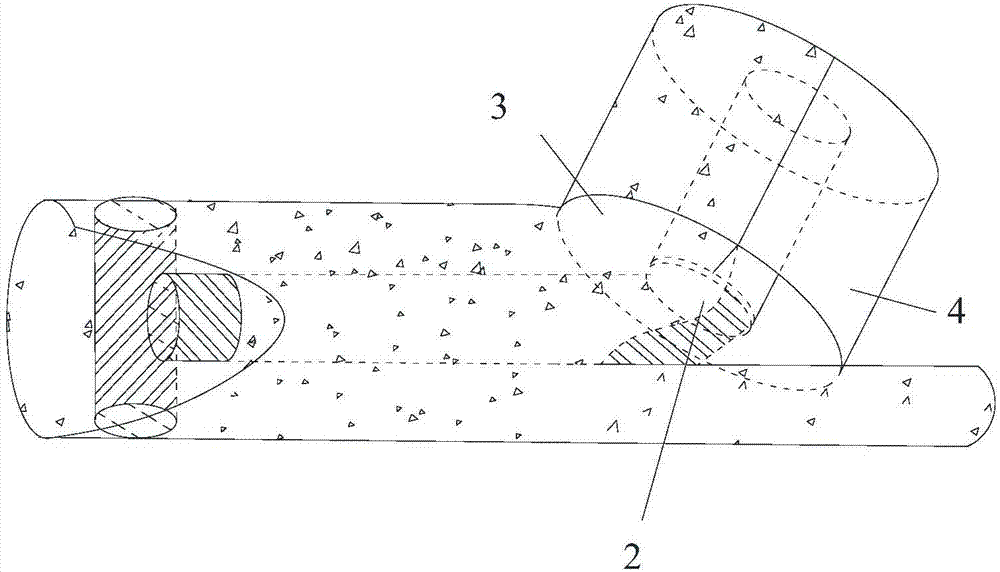

[0040] In this preferred embodiment, an implementation method of an integrated implementation device based on the above-mentioned 3D printing reinforced concrete structure includes the following steps:

[0041] Close the concrete sprinkler, open the reinforcement head, move (including horizontal, vertical or oblique) the reinforcement head according to the construction needs to make steel bars and cool to room temperature;

[0042] Close the reinforcement head, open the concrete nozzle, extrude the concrete that can embed the current reinforcement, and form a reinforced concrete integrated wrapping structure;

[0043] Repeat the above steps until all reinforced concrete structures meet the design requirements;

[0044] Normally close the reinforcement head, open the concrete sprinkler, and complete the pouring of other materials without reinforcement.

[0045] Specifically, the reinforcement head is moved at a constant speed during reinforcement. In addition, when carrying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com