Assembly-type residential shear wall structural wall body vertical connection construction method

A shear wall, prefabricated technology, applied in building construction, construction, building material processing, etc., can solve the problems of slow construction speed, high cost, difficult quality control, etc., to reduce the number of connections and reduce construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings and embodiments.

[0023] The construction method for the vertical connection of the prefabricated residential shear wall structure wall described in this embodiment is as follows:

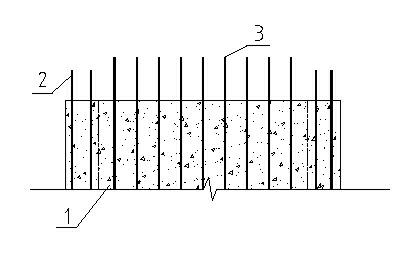

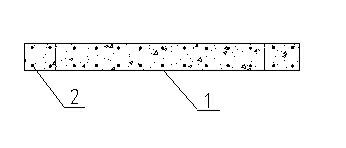

[0024] a. Prefabricated lower wall 1:

[0025] See figure 1 , figure 2 The outer elongation of the lower sleeve anchoring connecting steel bars at the leg positions of the lower wall 1 should meet the technical requirements of sleeve grouting, the anchoring length of the steel bars in the sleeve should be controlled within the range of 120-150mm, and the middle part of the steel bars should be laid The outer elongation of the lower lap connecting steel bar 3 of the connecting connection section is generally 41D (D is the diameter of the steel bar).

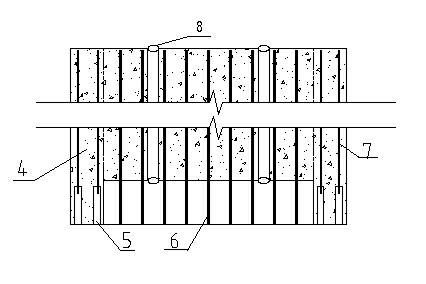

[0026] b. Prefabricated upper wall 4:

[0027] See image 3 , Figure 4 , The upper wall 4 has two anchor connecting sleeves 5 embedded in the concrete at the leg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com