Building waste residue sintering-free embedded pipeline groove brick and using method thereof

A technology of construction waste and pre-embedded pipelines, which is applied in the field of wall bricks, can solve the problems of difficult control of the size and depth of the groove, large labor, material and energy consumption, and large gaps in the inner holes of hollow bricks, etc., to achieve quality benefits and economy Obvious benefits, high construction efficiency, and less construction dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

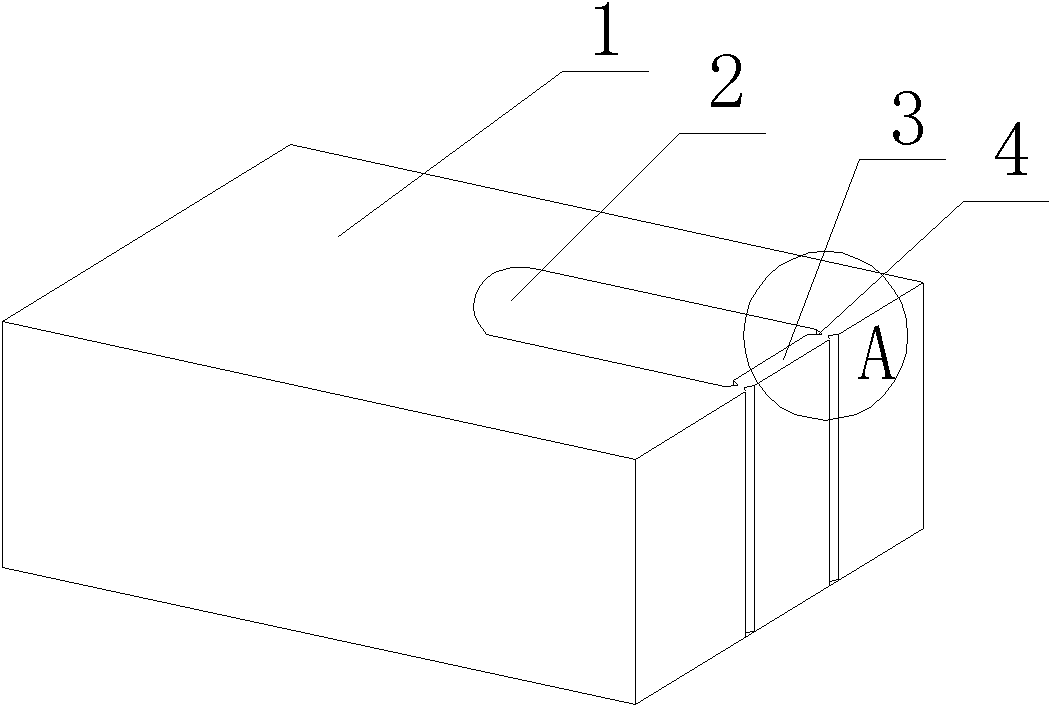

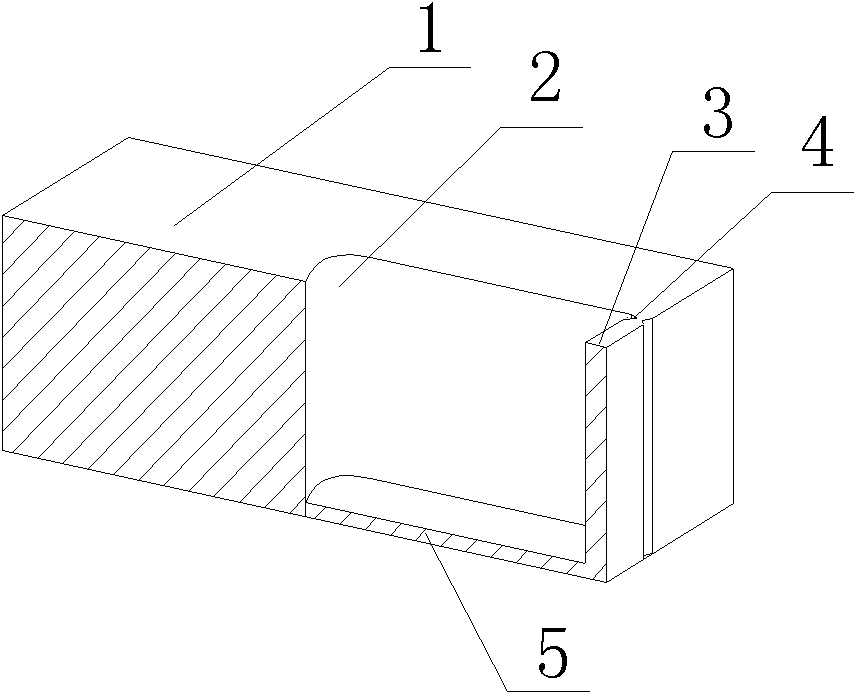

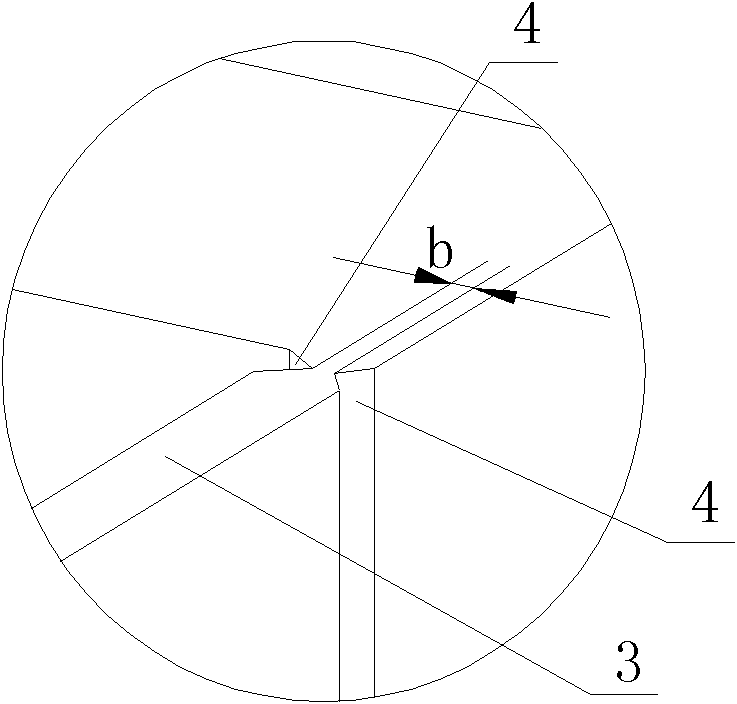

[0030] like figure 1 , figure 2 , image 3 As shown, a construction waste sinter-free pre-embedded pipeline channel brick includes a brick body 1, the brick body adopts a solid brick body, and the brick body 1 is provided with a cutout 2, and the cutout groove 2 is a U-shaped groove, In order to ensure the use performance of the brick body, the length of the cut groove 2 shall not exceed half of the brick body 1, the cut groove 2 is located in the middle of the width direction of the brick body, and the end of the cut groove 2 is provided with a reserved layer 3, and the cut groove 2 is provided with a reserved layer 3. The bottom of the groove 2 is provided with a surface layer 5 flush with the bottom surface of the brick body 1, and the surface layer 5 is convenient for plastering. In order to ensure the load-bearing performance of the brick body 1 and facilitate rapid knock-off, the thickness of the reserved layer 3 is not more than 8mm. The functions of the reserved la...

Embodiment 2

[0040] like Figure 4 As shown, a construction waste sinter-free pre-embedded pipeline trough brick includes a brick body 1. The brick body is a hollow brick body. The brick body 1 is provided with a slot 2. In order to ensure the performance of the brick body, the slot 2 The length of the groove is not more than half of the brick body 1, the distance a between the side wall of the cut groove 2 and the side wall of the brick body 1 is not less than 20mm, the end of the cut groove 2 is provided with a reserved layer 3, and the cut groove The bottom of 2 is provided with the surface layer 5 flush with brick body 1 bottom surface, and surface layer 5 is the effect that is convenient to plastering. In order to ensure the load-bearing performance of the brick body 1 and facilitate rapid knock-off, the thickness of the reserved layer 3 is not more than 8mm. The functions of the reserved layer are: convenient for transportation; the bricks of the reserved layer can be used as ordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com