Friction type high-strength bolt capable of monitoring and controlling pretension force, connecting piece and construction method thereof

A high-strength bolt and pre-tension technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of increasing engineering costs and reducing utilization, saving labor costs, enhancing utilization, and high prefabrication. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0055] Figure 1a with Figure 1b Schematic diagram of a stud shear connection for a prior art beam or slab setup. It can be seen from the figure that the shear connector needs to be welded on the beam or plate, which is labor-intensive and wastes material.

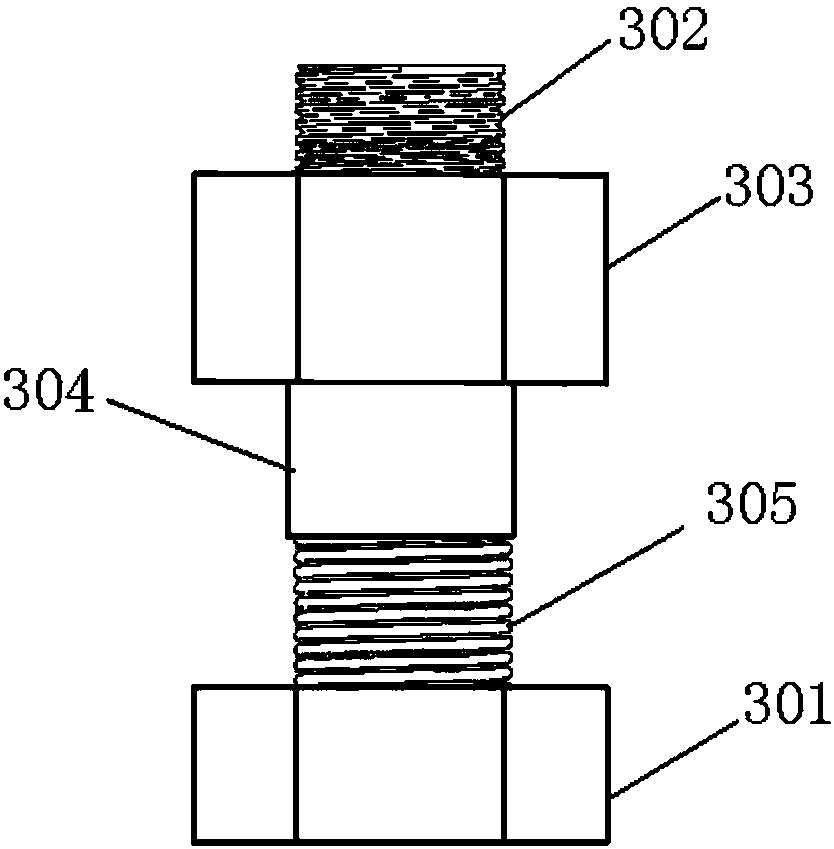

[0056] Therefore, a friction-type high-strength bolt that can monitor and control pretension is provided, such as Figure 2-Figure 10 As shown, it includes a screw section 302 provided with at least one threaded portion, a first nut 301 and a second nut 303 screwed to the screw section, a semiconductor sleeve set on the screw section and located between the first nut and the second nut Spring 305, a sleeve 304 sleeved on the outer periphery of the semiconductor spring, a positive and negative metal sheet 307 that is arranged on one side of the first nut or the second nut and can be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com