A normal-temperature health-preserving type steel bridge deck pavement structure and a construction method thereof

A bridge deck pavement, room temperature technology, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as residual stress, inconvenient maintenance and reduction of driving comfort, etc. The effect of reducing free water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

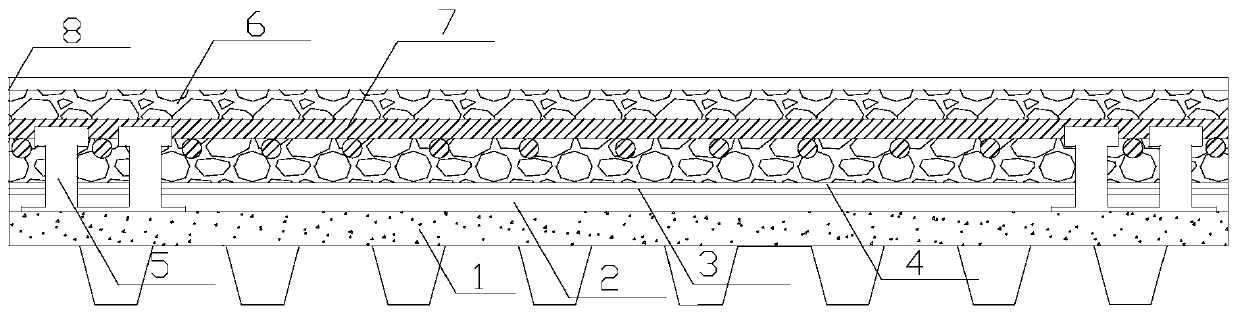

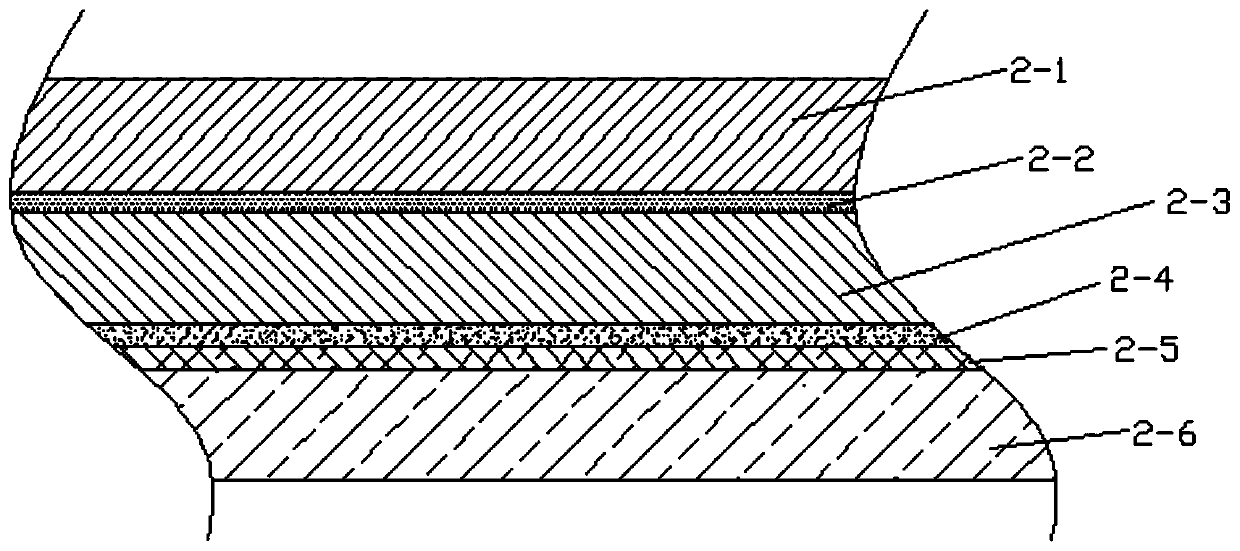

[0066] The normal-temperature health-preserving steel bridge deck pavement structure of the present invention comprises a steel plate 1, a stress-absorbing layer 2, an epoxy resin crushed stone anti-shear layer 3, a wet joint interface agent layer 4, a strip steel floor anti-shear stud 5, and a normal-temperature health-preserving type Ultra-high toughness cement concrete layer 6, double-layer steel mesh 7 and resin crushed stone wear layer 8.

[0067] It includes a steel plate 1, on the upper surface of the steel plate 1, there are strip steel bottom plate shear studs 5, on the strip steel bottom plate shear studs 5, a stress absorbing layer 2 is set, and on the stress absorbing layer 2, epoxy resin chips are set. The stone shear layer 3 is provided with a double-layer steel mesh 7 on the upper surface of the epoxy resin crushed stone shear layer 3, and a wet interface agent layer 4 is arranged on the double layer steel mesh 7, and a wet interface agent layer 4 is arranged on ...

Embodiment 2

[0089] On the basis of the pavement structure of the room-temperature health-preserving type steel bridge deck in Embodiment 1, in this embodiment, the distance between the shear studs in the horizontal bridge direction is 30 cm, the distance between the longitudinal bridge direction is 20 cm, and the thickness of the stress-absorbing layer 2 is 7 mm. The thickness of the ductile cement concrete layer 6 is 42mm, which is formed by binding Double-layer steel mesh 7, the distance between steel bars is set to 60mm, the distance between the steel mesh layer of the longitudinal bridge and the epoxy resin crushed stone shear layer 3 is 8mm, and the distance between the steel mesh layer of the horizontal bridge and the normal temperature health-preserving ultra-high toughness cement concrete layer 6 The surface distance is 14mm (protective layer thickness).

[0090] On the basis of embodiment one, change the proportioning of normal-temperature health-preserving type ultra-high tough...

Embodiment 3

[0093] On the basis of the pavement structure of the room-temperature health-preserving steel bridge deck in Example 1, in this embodiment, the shear studs have a horizontal distance of 40 cm and a longitudinal distance of 10 cm, and the thickness of the stress-absorbing layer 2 is 5 mm. The thickness of the ductile cement concrete layer 6 is 44mm, which is formed by binding Double-layer steel mesh 7, the distance between the steel bars is set to 80mm, the distance between the steel mesh layer of the longitudinal bridge and the epoxy resin crushed stone shear layer 3 is 10mm, and the distance between the steel mesh layer of the horizontal bridge and the normal-temperature health-preserving ultra-high toughness cement concrete layer 6 Surface distance is 10mm (thickness of protective layer).

[0094] On the basis of embodiment one, change the proportioning of normal-temperature health-preserving type ultra-high toughness cement concrete, specifically as follows:

[0095] In a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com