A prefabricated assembly dry-type connection frame structure system and its construction method

A connecting frame and prefabricated assembly technology, which is applied in the direction of building components, building structures, protected buildings/shelters, etc., can solve problems such as unreliable joint connections, poor seismic performance of structures, and complicated construction, and optimize the construction process , Reliable node connection, solve the effect of heavy wet work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

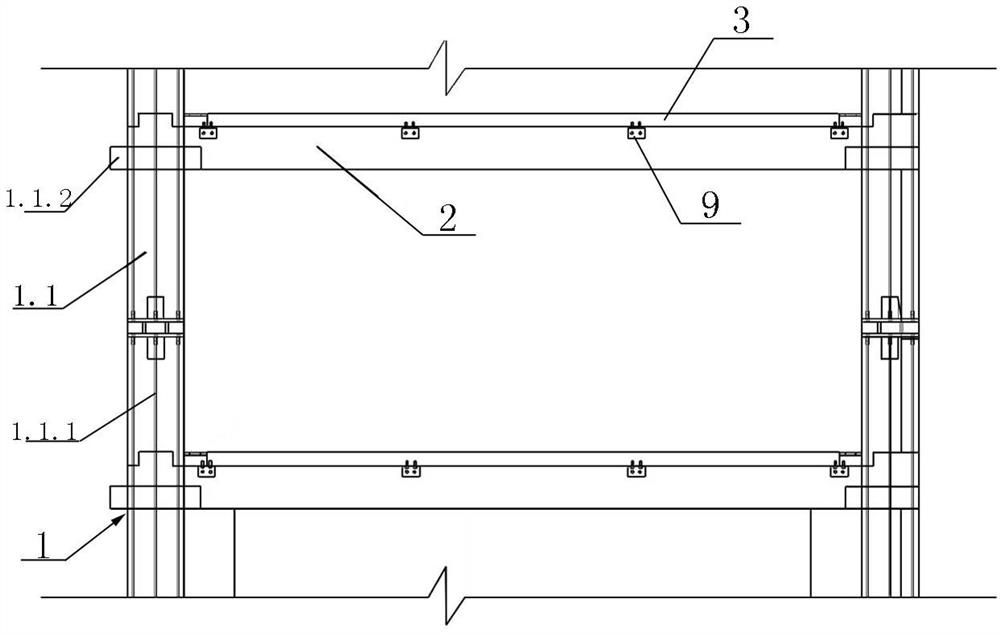

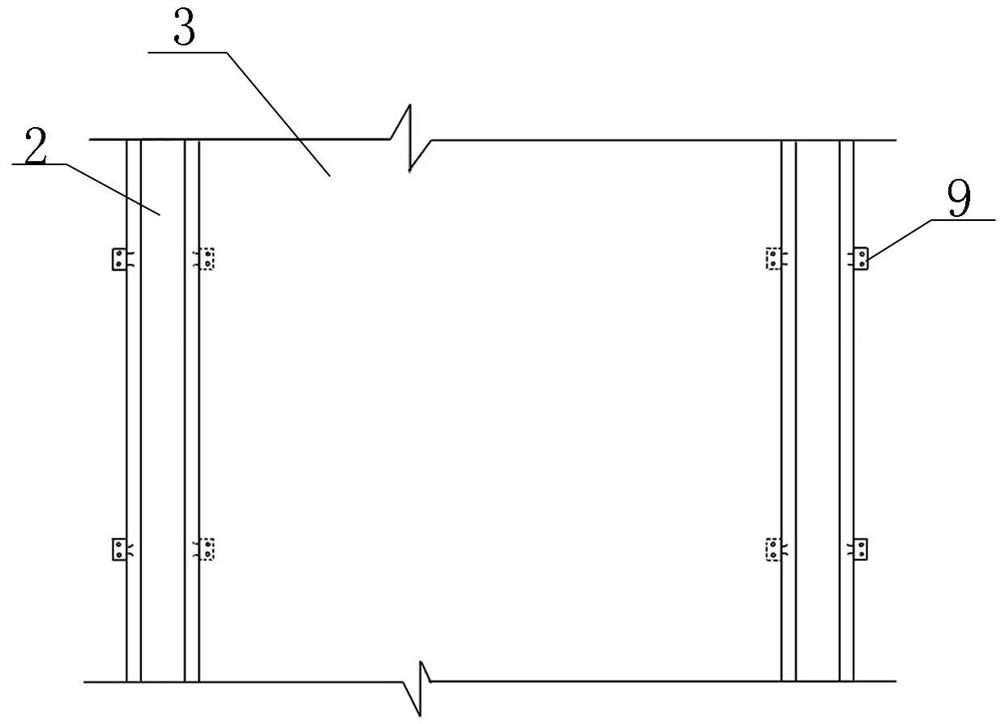

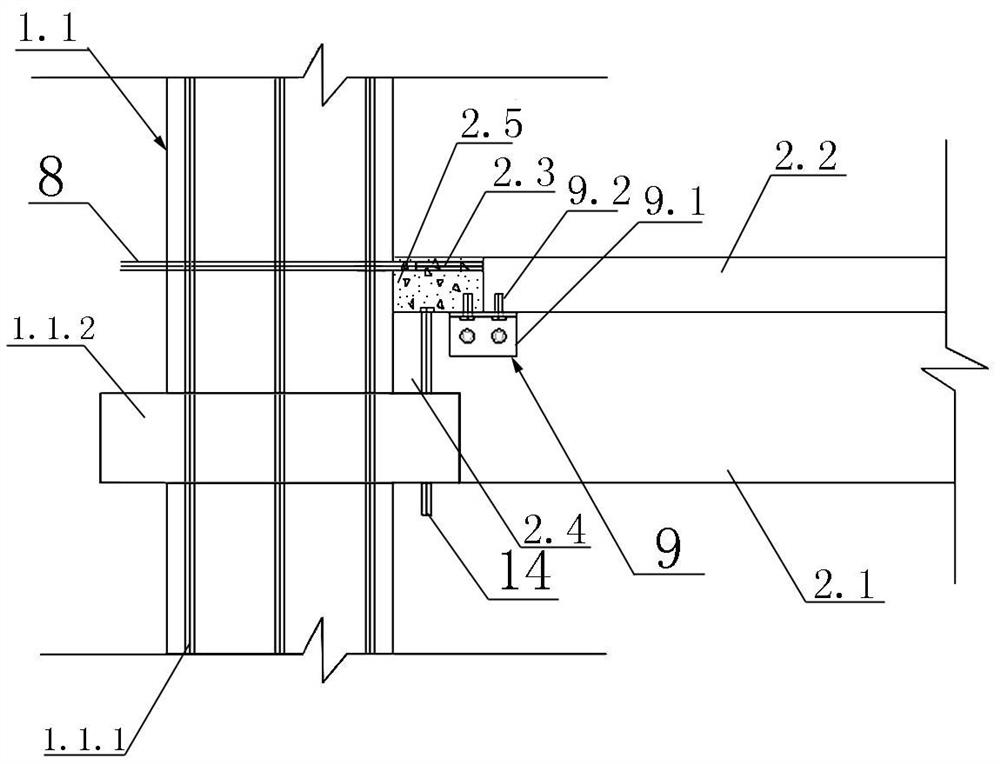

[0038] The prefabricated and assembled dry-type connection frame structure system of the present invention is designed to meet the special needs of island construction that is greatly affected by the natural environment, meet the special needs of tight construction schedules and heavy tasks, and promote the standardization of the assembly unit production of the frame structure system. The prefabrication of factory manufacturing and on-site assembly is designed The frame structure system with dry connection is assembled to achieve the effect of good seismic performance of the structure system, reliable node connection and convenient construction.

[0039] According to the node connection form of the prefabricated assembly dry connection frame structure system, the present invention is based on the finite element theory, and establishes a finite element model to perform mechanical analysis on the prefabricated assembly dry connection frame structure system to verify the reliabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com