A low-level multi-storey assembled beam-column joint

A prefabricated, beam-column technology, which is applied in the direction of construction and building construction, can solve the problems of difficulty in ensuring the quality of on-site welding between steel beam ends and steel columns, the eccentric force of steel beams, and the large amount of welding of clapboard joints. , to achieve the effect of simplifying the difficulty of construction work, strengthening the strength and improving the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

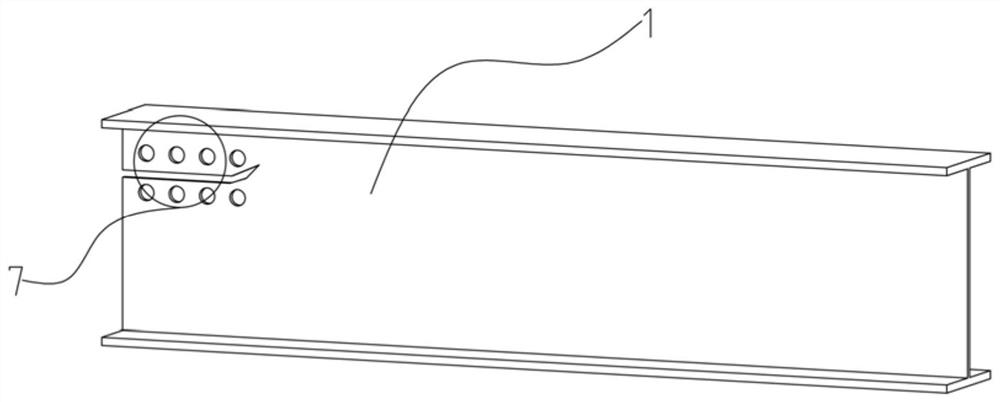

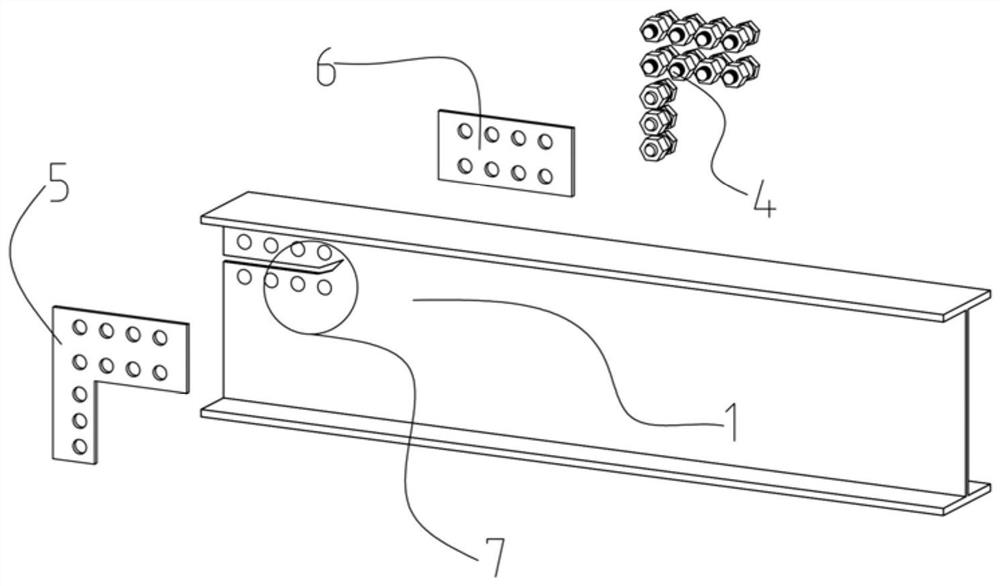

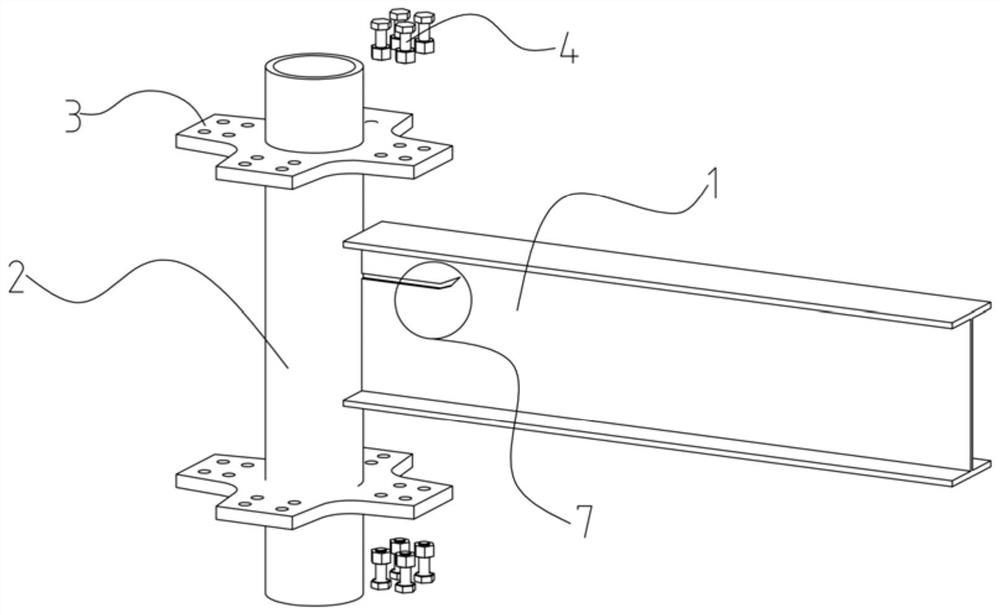

[0024] The present invention is further described below in conjunction with accompanying drawing:

[0025] see Figure 1 to Figure 6 , a low multi-layer assembled beam-column splicing node, including steel column 2, steel beam 1, web connection assembly and cover plate 3; a through hole is provided at the center of cover plate 3, and two cover plates 3 are fixedly sleeved on On the steel column 2, several steel beams 1 are fixed between the two cover plates 3, and the angle between adjacent steel beams 1 is 90° or 180°; the end of the steel beam 1 close to the steel column 2 is provided with Web connection components. Compared with the traditional diaphragm-type joints, the setting of the cover plate avoids the need to cut off the columns due to the setting of the diaphragm, thereby reducing the welding amount of the columns, diaphragms and beams. Effectively avoid cracks, pores, slag inclusions, incomplete penetration, and incomplete penetration defects during the welding p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com