High-wear-resistance high-frequency induction welded steel pipe raw material steel and preparation method and application thereof

A high-frequency induction welding, high wear-resistance technology, applied in the field of steel rolling, can solve the problems of easy cracking, inability to make pipes, and cannot be applied to the pipe-making industry, etc., to improve wear resistance and significantly increase the rate of work hardening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

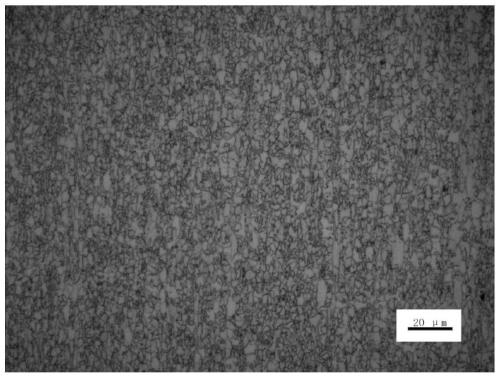

Image

Examples

Embodiment 1

[0071] Embodiment 1: Preparation of high-frequency induction welded steel pipe according to the present invention

[0072] 1. Preparation of high-frequency induction welded steel pipe raw material steel with high wear resistance according to the present invention

[0073] (1) Add molten iron to converter smelting and continuous casting to obtain continuous casting billets, wherein; in terms of mass percentage, the continuous casting billets include: C 0.15%, Mn 0.5%, P≤0.008%, S≤0.005%, Al 0.03%, Nb 0.03%, V0.03%, the rest is Fe and unavoidable impurities;

[0074] (2) Heating the continuous casting steel slab described in step (1) to 1100° C., and keeping it warm for 120 minutes;

[0075] (3) Roughly rolling the continuous casting slab obtained in step (2) to obtain an intermediate slab; coiling the intermediate slab to obtain an intermediate steel coil; decoiling the intermediate steel coil, and then performing finish rolling , to obtain strip steel; in this step, when t...

Embodiment 2

[0089] Embodiment 2: Preparation of high frequency induction welded steel pipe according to the present invention

[0090] 1. Preparation of high-frequency induction welded steel pipe raw material steel with high wear resistance according to the present invention

[0091] (1) Put molten iron into the converter for smelting and continuous casting to obtain continuous casting steel slabs, wherein; in terms of mass percentage, the continuous casting steel slabs include: C 0.20%, Si 0.05%, Mn 1.3%, P≤0.008%, S≤ 0.005%, Al 0.04%, Nb0.08%, V 0.1%, the rest is Fe and unavoidable impurities;

[0092] (2) Heating the continuous casting billet described in step (1) to 1200° C., and keeping it warm for 150 minutes;

[0093] (3) Roughly rolling the continuous casting slab obtained in step (2) to obtain an intermediate slab; coiling the intermediate slab to obtain an intermediate steel coil; decoiling the intermediate steel coil, and then performing finish rolling , to obtain strip ste...

Embodiment 3

[0107] Embodiment 3: Preparation of high-frequency induction welded steel pipe according to the present invention

[0108] 1. Preparation of high-frequency induction welded steel pipe raw material steel with high wear resistance according to the present invention

[0109] (1) Put molten iron into converter for smelting and continuous casting to obtain continuous casting billet, wherein; by mass percentage, the continuous casting billet contains: C 0.16%, Mn 0.5%, P≤0.008%, S≤0.005%, Al 0.03%, Nb 0.04%, V0.04%, the rest is Fe and unavoidable impurities;

[0110] (2) Heating the continuous casting steel slab described in step (1) to 1100° C., and keeping it warm for 120 minutes;

[0111](3) Roughly rolling the continuous casting slab obtained in step (2) to obtain an intermediate slab; coiling the intermediate slab to obtain an intermediate steel coil; decoiling the intermediate steel coil, and then performing finish rolling , to obtain strip steel; in this step, when the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com