Steel-concrete shear connector and preparation method thereof

A technology of shear connectors and concrete, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of distributed steel bars not on the same plane, single function of steel bars, high difficulty, etc., and achieve the effect of improving economy and construction convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

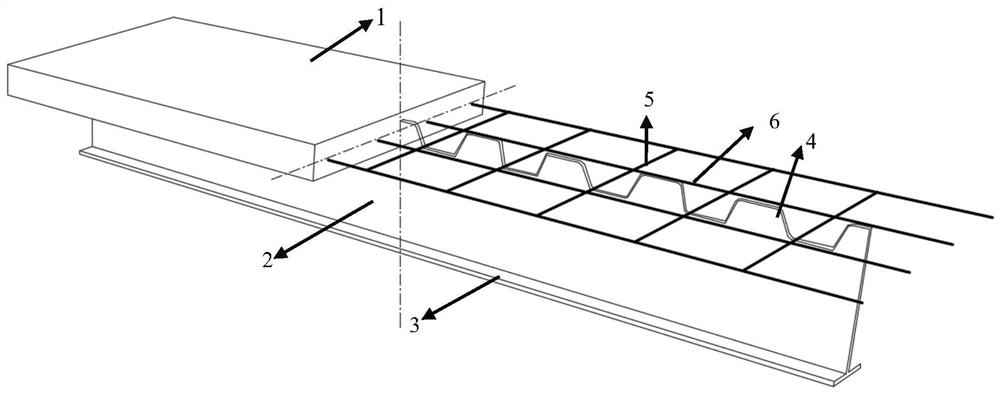

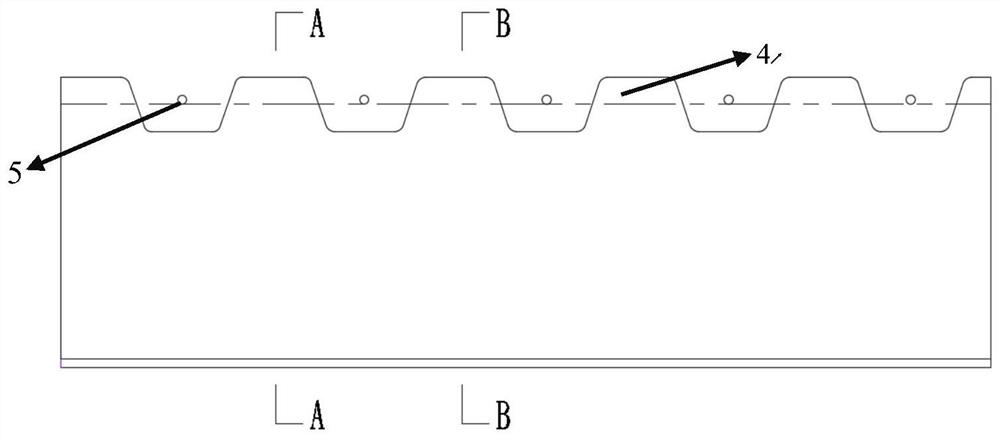

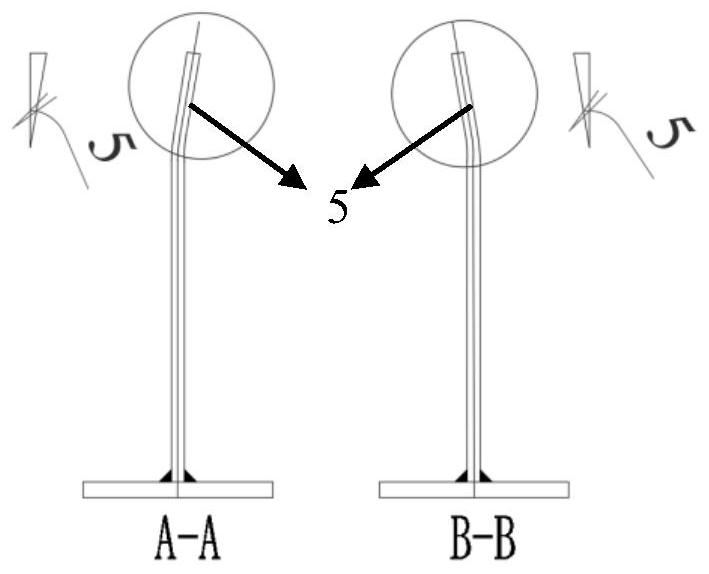

[0022] Below in conjunction with the embodiment shown in the accompanying drawings, the utility folding shape is further described.

[0023] The cutting track of the steel plate by the CNC machine tool is a centrally symmetrical figure, and after one cutting of the steel plate, two identical steel beam webs 1 with folded tooth-shaped shear connectors can be obtained. A rolling machine is used to alternately roll out shear connectors 2 with a certain kink angle toward the left and right sides. The shape of the shear connector 2 is changeable, and its bending angle facing out of the plane can be adjusted according to the actual situation.

[0024] figure 1 It is a schematic diagram of the shear connector in the present invention.

[0025] On the premise of ensuring the shear bearing capacity and ductility of the shear connectors, a folded toothed shear connection with better economic performance and more convenient construction has been developed. Main train of thought of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com