Partially-prestressed reinforced concrete solid square pile upper segment and manufacturing method thereof

A technology of reinforced concrete and manufacturing methods, which is applied to sheet pile walls, manufacturing tools, ceramic molding machines, etc., can solve the problems that the pile body cannot meet the mechanical properties, pile sinking construction requirements, and inconvenient pile cutting, etc., to meet the requirements of pile sinking Construction requirements, improving the tensile bearing capacity of the pile body, and the effect of improving the crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

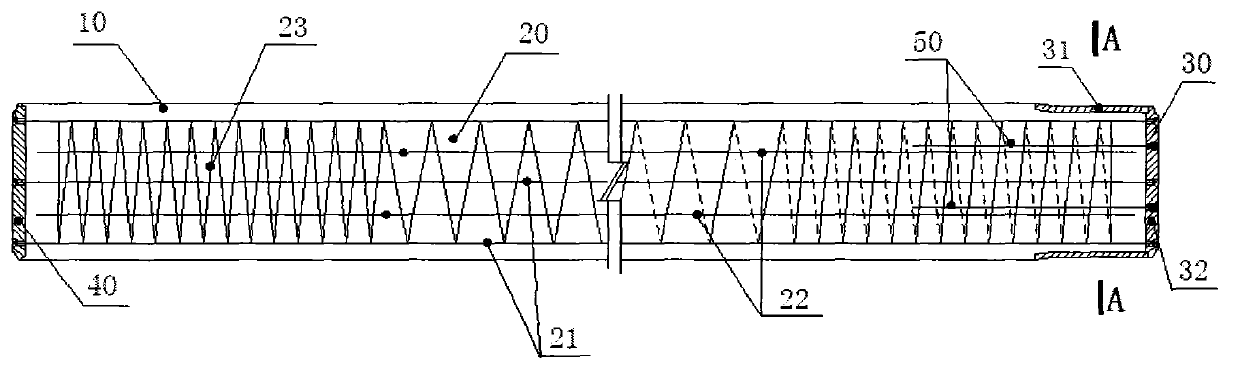

[0030] figure 1 It is a schematic diagram of the longitudinal structure of Embodiment 1 of the upper section of the partially prestressed reinforced concrete solid square pile of the present invention.

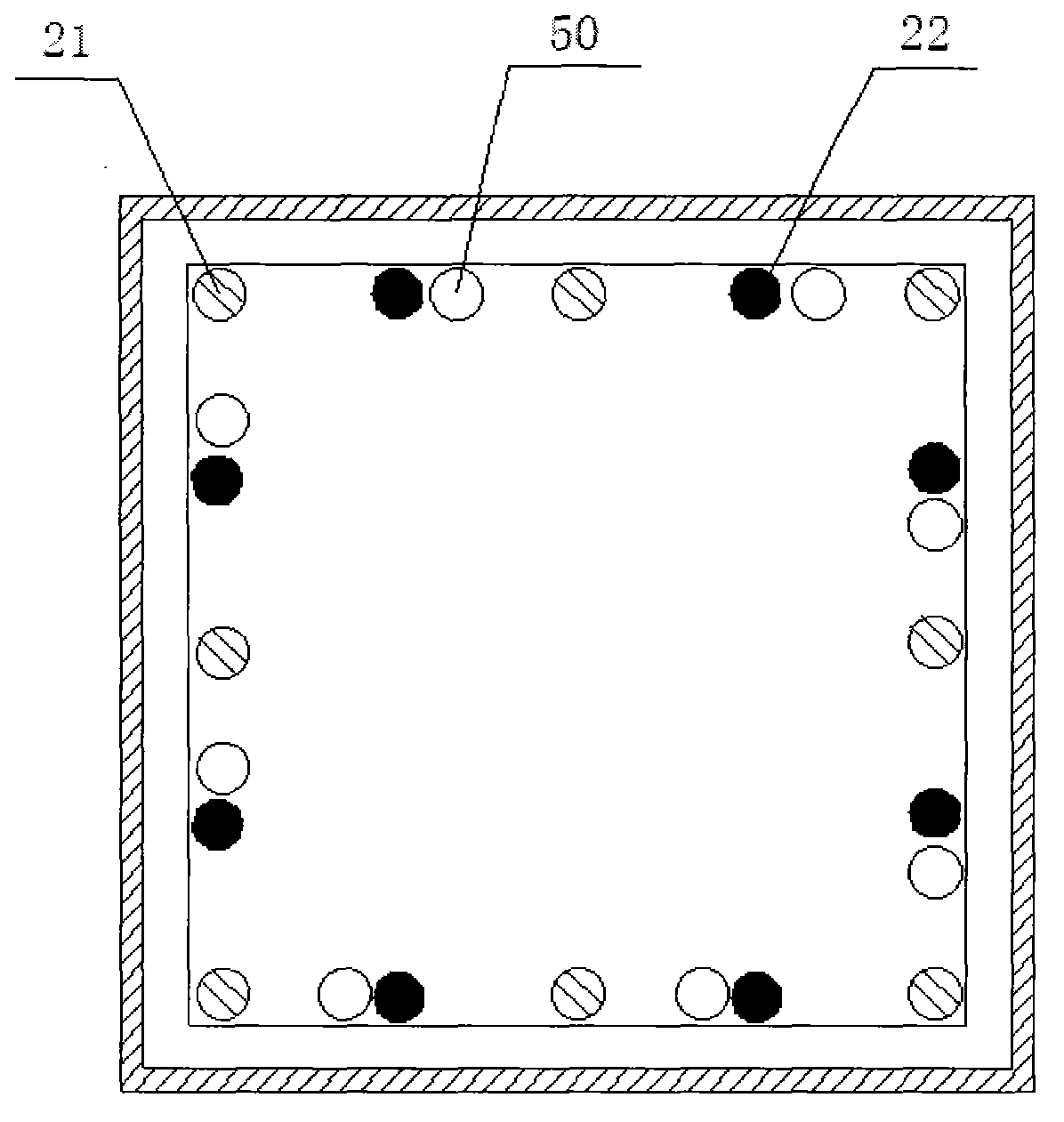

[0031] figure 2 is along figure 1 Sectional view of line A-A.

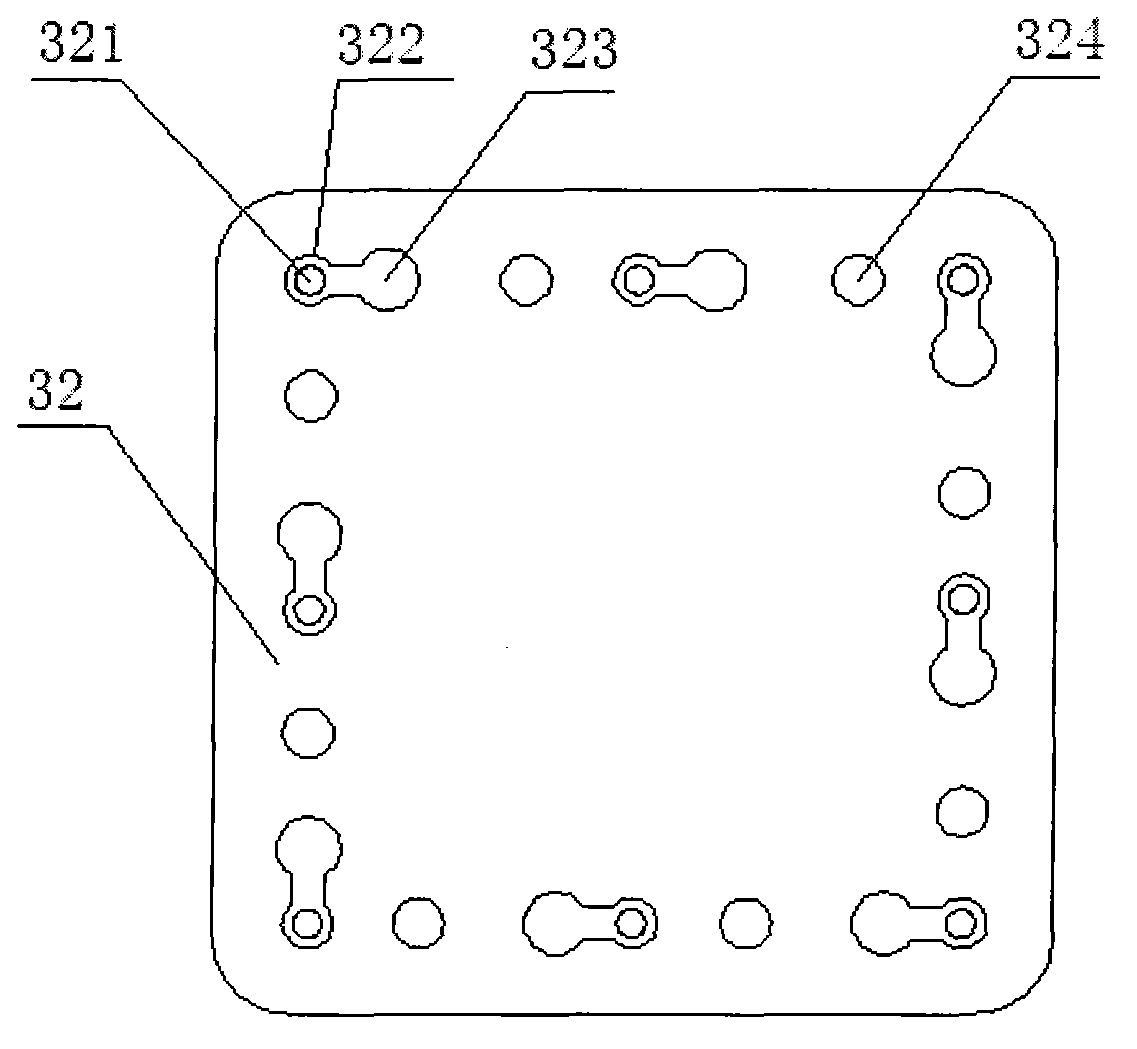

[0032] Such as figure 1 , figure 2 As shown, the upper part of the partially prestressed reinforced concrete solid square pile of the present invention includes: concrete 10 , steel cage 20 , pile cap 30 and fixed end plate 40 .

[0033] The reinforcement cage 20 is a square combined overall structure, one end of which is fixedly connected to the pile cap 30 , and the other end is fixedly connected to the fixed end plate 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com