Double-ripple ventral shield steel case built-up beam

A technology of composite beams and double corrugations, which is applied to floors, structural elements, building components, etc., can solve the problems that traditional products are difficult to meet the requirements, it is difficult to realize automatic production, and increase the processing workload, so as to achieve beautiful welds without spatter , Excellent anti-fatigue performance, excellent light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

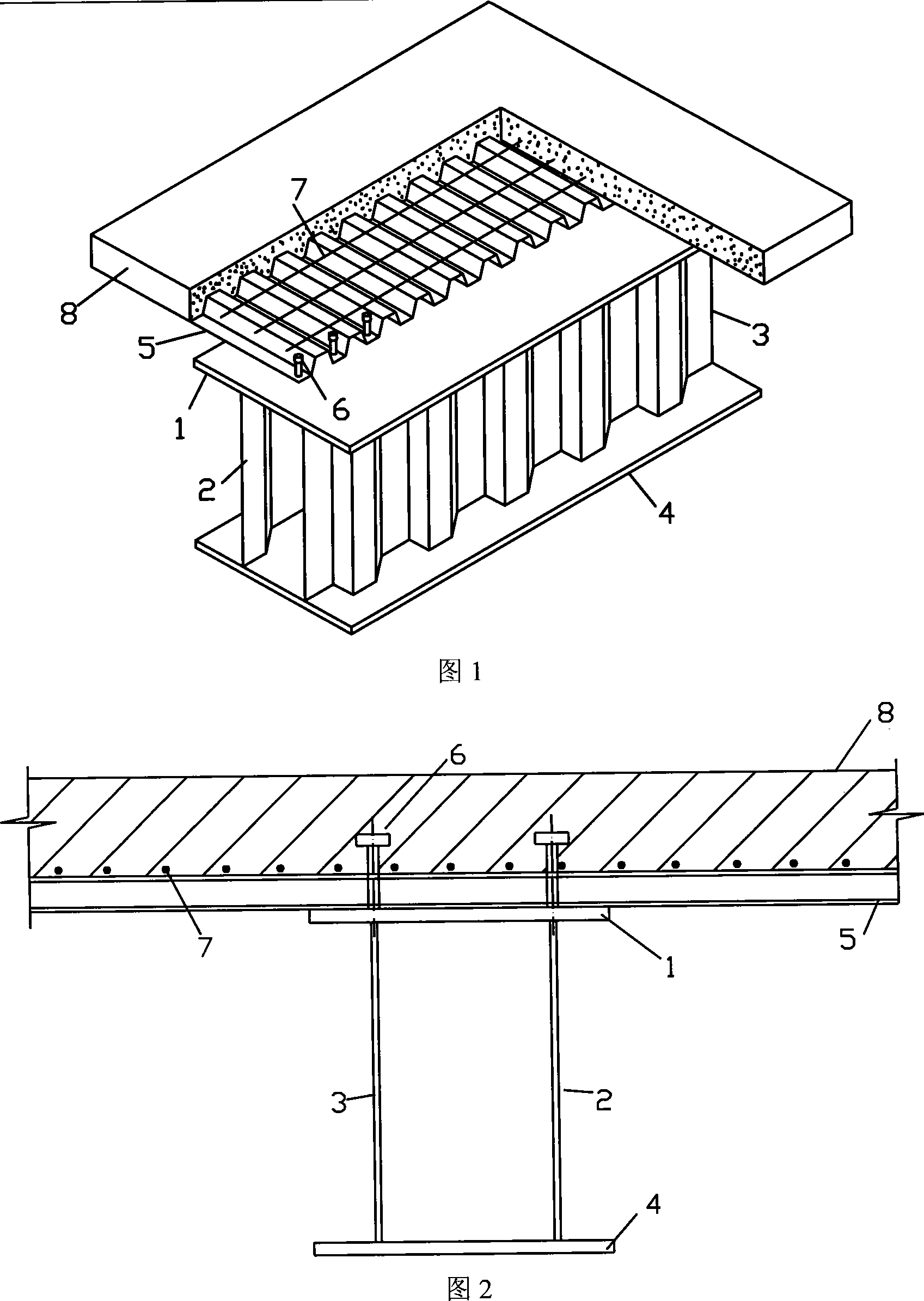

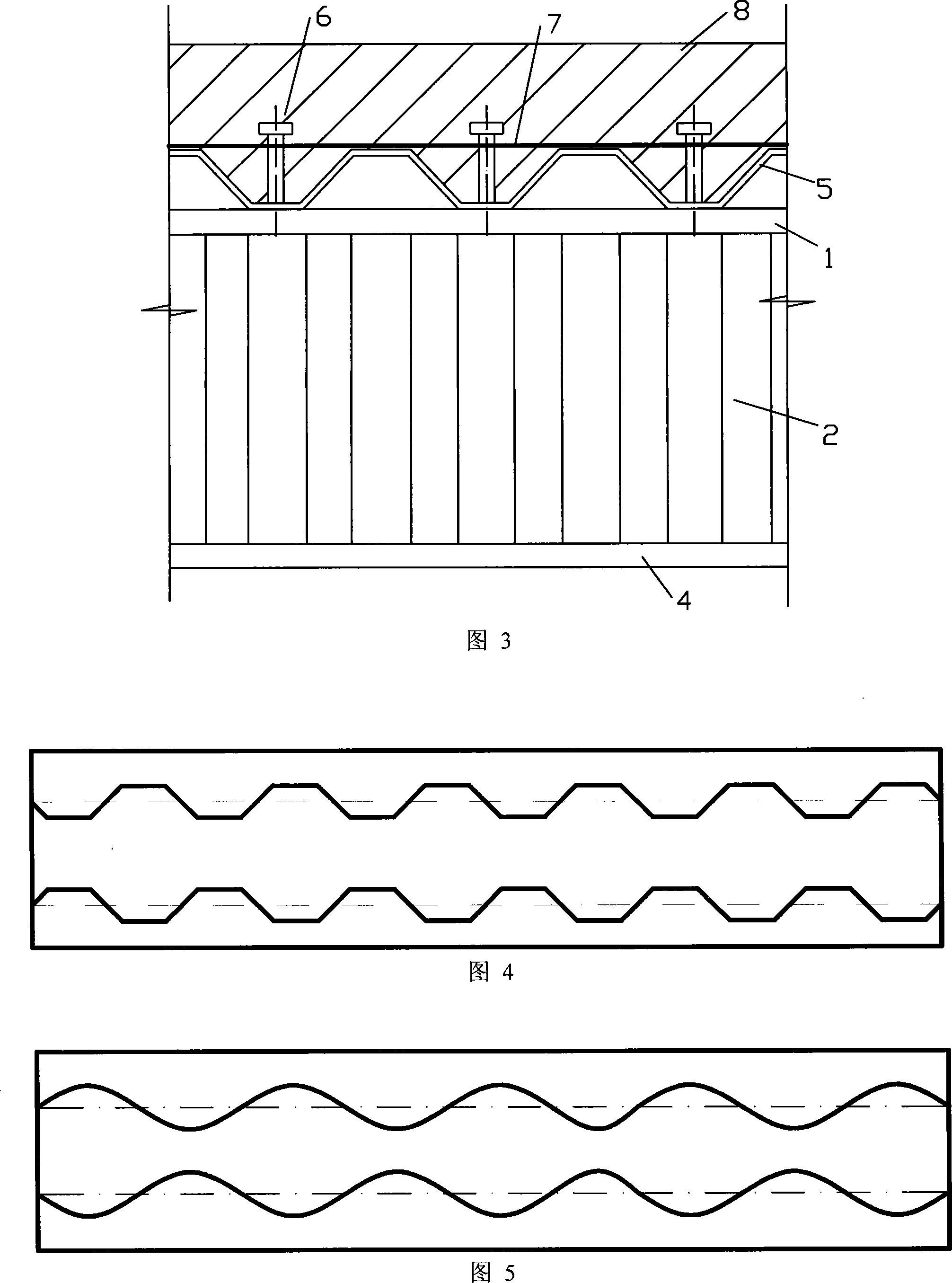

[0037] Example 1: The cross-section shape of the double corrugated web steel box composite girder is composed of the middle web 2, web 3, upper flange 1, and lower flange 4. The upper flange 1 is parallel to the lower flange 4. , the web 2 and the web 3 are perpendicular to the upper flange 1 and the lower flange 4, and the cross-sectional shape of the web 2 and 3 is trapezoidal. The reinforced concrete wing plate 8 is located above the profiled steel plate 5, the profiled steel plate 5 is located above the upper flange 1, the reinforced concrete wing plate 8, the profiled steel plate 5, and the upper flange 1 are fixed by the tack 6, and the transverse reinforcement 7 Welded on the profiled steel plate 5 tops.

[0038] In order to verify the performance of the device, a test piece was made for research. The steel materials in the test pieces are all made of Q235 steel, the thickness of the reinforced concrete wing plate 8 is 100 mm, and C20 concrete is used, the stud 6 is ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com