Forming explosive column/block mechanical disruption device

A technology of mechanical crushing and explosives, applied in the direction of grain processing, etc., can solve the problems of poor particle size uniformity, damage, economic loss, etc., to achieve the effect of inhibiting continued growth or expansion, achieving uniform particle size, and achieving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

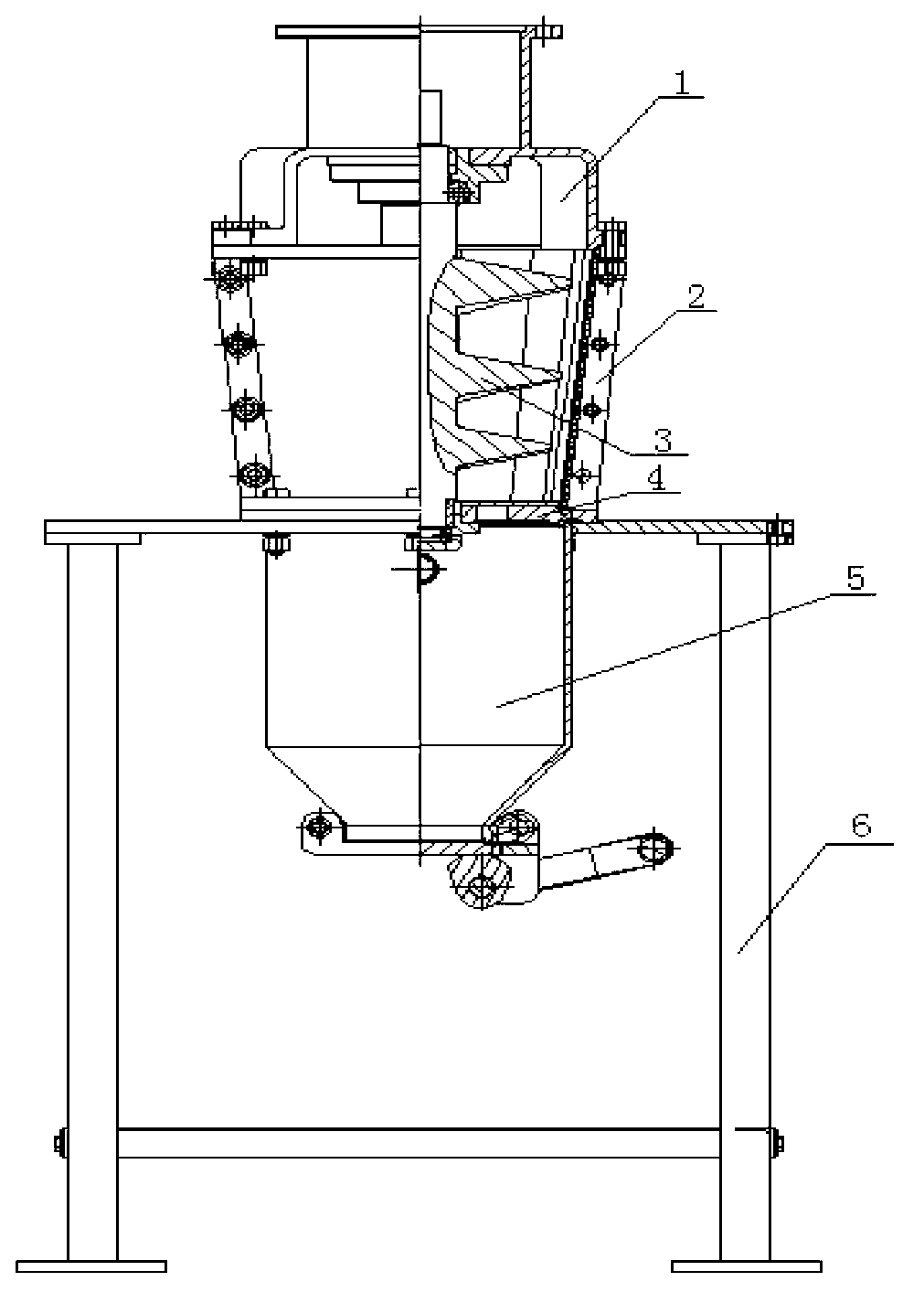

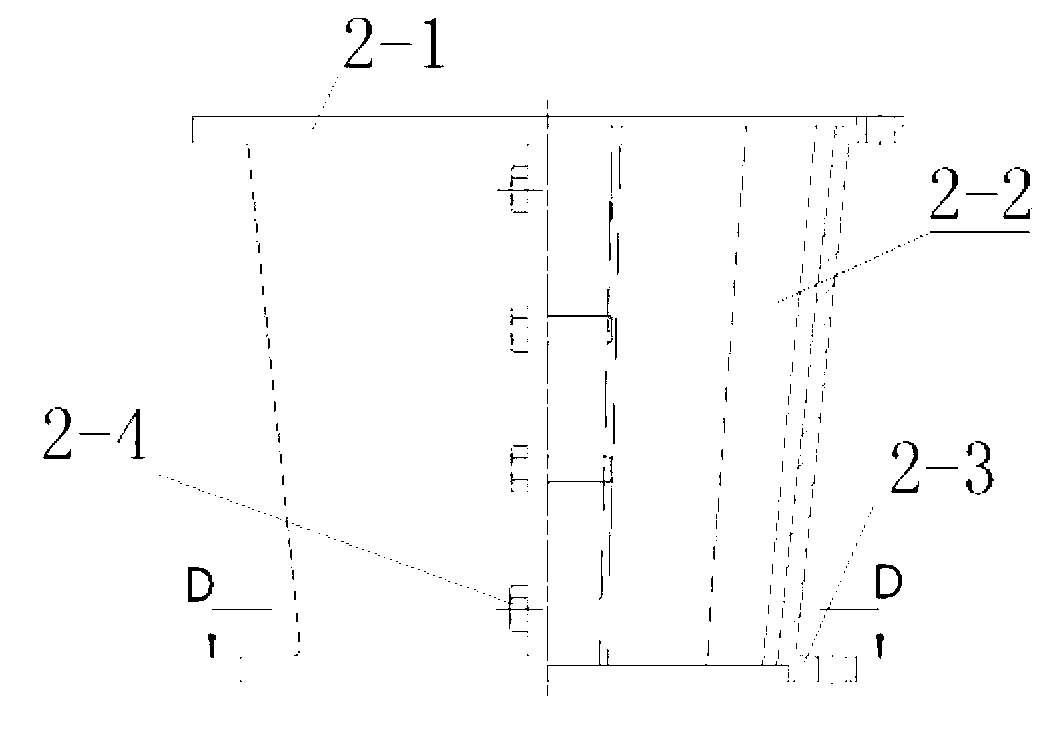

[0027] refer to Figure 1 to Figure 8 , this embodiment gives a specific structure and manufacturing and assembly example of a shaped explosive column / block mechanical crushing device. The shaped explosive column / block mechanical crushing device at least includes a feeding cylinder 1 , a crushing cartridge 2 , a variable pitch worm 3 , a sieve plate 4 , a feeding cylinder 5 and a bracket 6 .

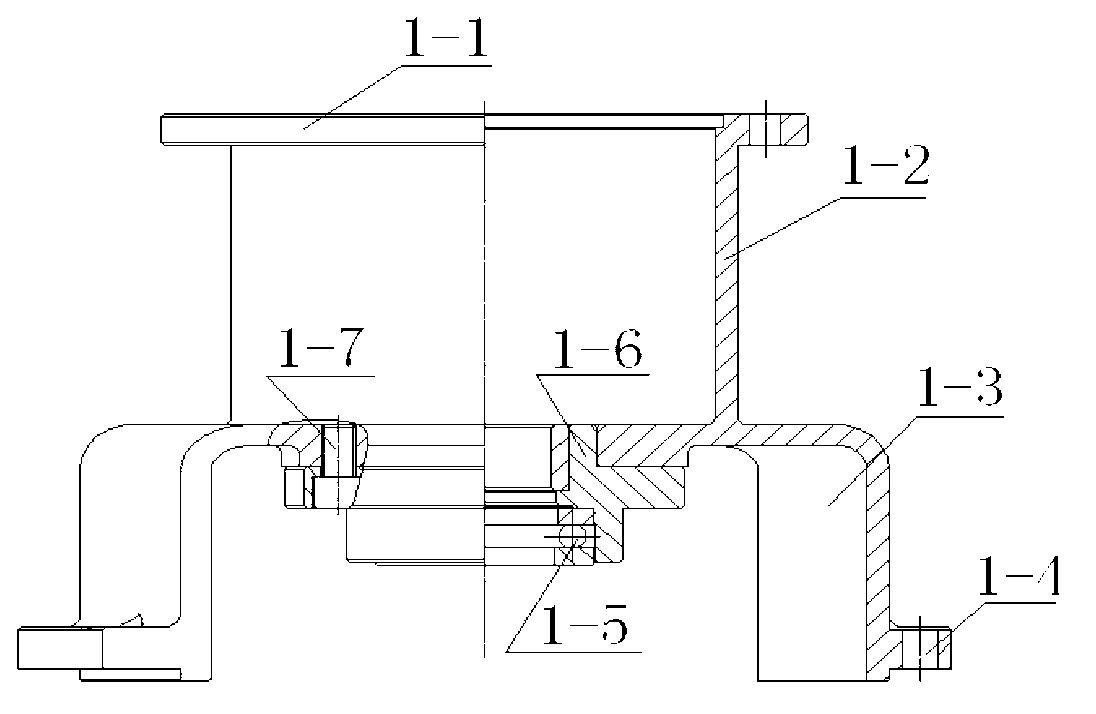

[0028] see figure 2 , There are flanges at both ends of the feeding cylinder 1, the upper end is an open cylinder, and the lower end is in the shape of an inverted basin. The specific structure includes: an upper flange 1-1, an upper straight cylinder 1-2, a feed inlet 1-3, a lower flange 1-4, a rolling bearing 1-5, a bearing frame 1-6 and fastening bolts 1-7. The upper straight cylinder 1-2 and the feed inlet 1-3 are integrally cast with cast steel, with a thickness of 8mm to 10mm; the upper straight cylinder 1-2 has a height of 100mm, an outer diameter of 170mm, and the height of th...

Embodiment 2

[0038] This embodiment provides the press-packed explosive column 10 by using the shaped explosive column / block mechanical crushing device prepared in Example 1. # -159 broken instances.

[0039] The used shaped explosive 10 of the present embodiment # The charge of -159 is cylindrical in shape with a size of 120mm in diameter and 135mm in height.

[0040] Before breaking the powder column, inject tap water into the water bath, and the water surface height reaches the upper end surface of the feed port 1-3, and 10 # -159 explosive column is put into the crushed cartridge 2 through the feed port 1-3, turn on the power supply of the explosion-proof speed-regulating motor, adjust the motor speed to 5rad / min~10rad / min, the rotation of the explosion-proof speed-regulating motor drives the variable-pitch worm 3 at the same speed Rotate, so that the drug column is broken under the extrusion action of the variable pitch worm 3 and the barrel 2-2 of the crushing cartridge 2. Through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com