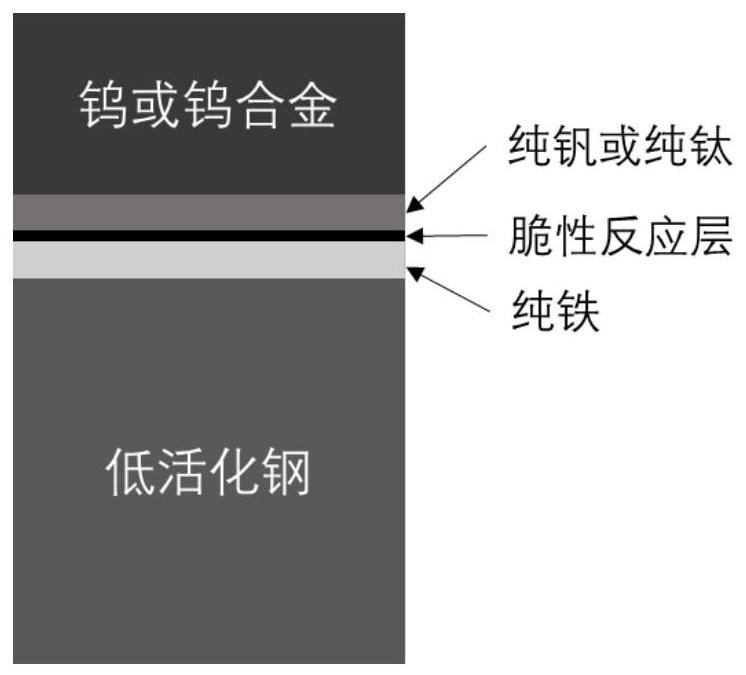

A Diffusion Bonding Method of Tungsten and Low-Activation Steel

A low-activation steel and diffusion bonding technology, which is applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of reducing the thermal fatigue resistance of the interface, increasing the thickness of the reaction layer, reducing the joint strength and plasticity, etc. , to achieve excellent thermal fatigue resistance, inhibition of initiation and expansion, and high connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

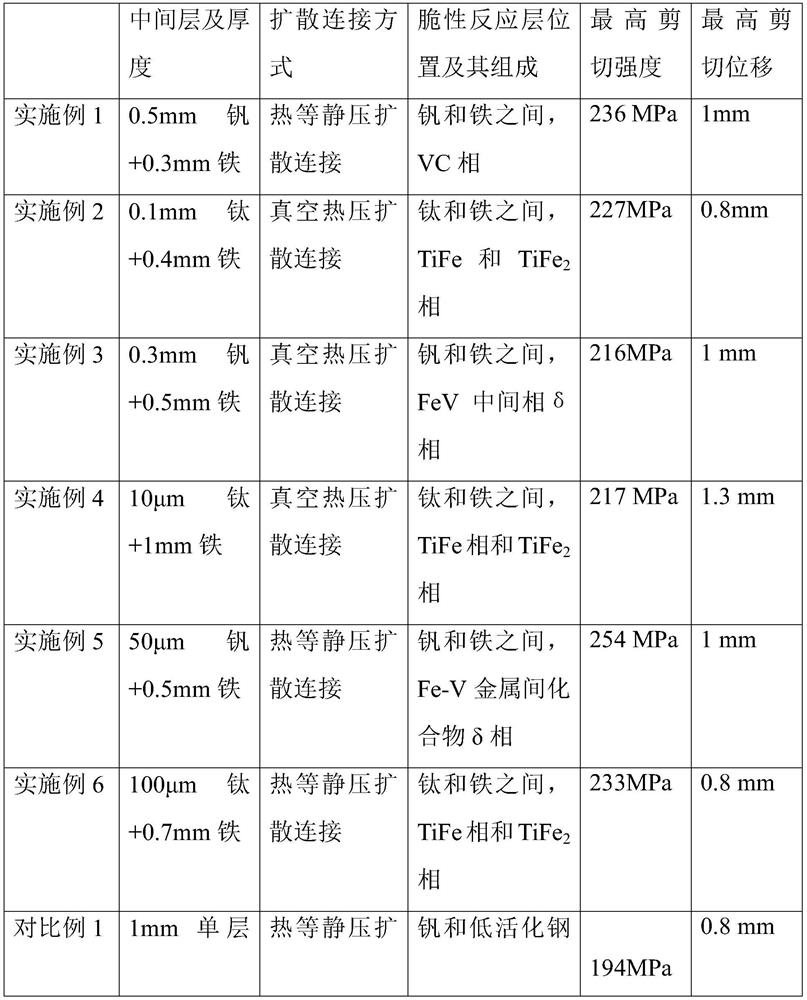

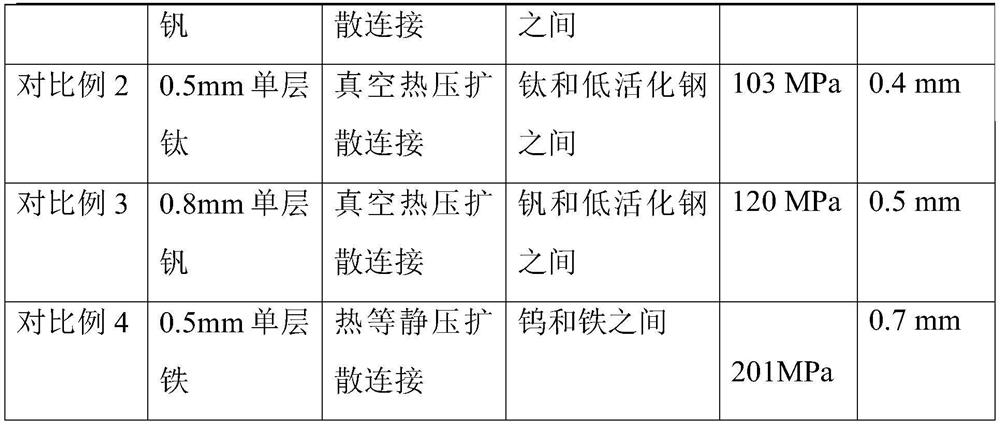

Embodiment 1

[0035] Embodiment 1 Preparation of tungsten / vanadium / iron / low activation steel joint

[0036] 1) Process pure tungsten, pure vanadium, pure iron and low activation steel into sizes of 30mm×30mm×3mm, 30mm×30mm×0.5mm, 30mm×30mm×0.3mm and 30mm×30mm×30mm respectively;

[0037] 2) Carry out vacuum softening annealing treatment on pure vanadium foil and pure iron foil. -3 Pa;

[0038] 3) Use SiC sandpaper to polish the surface of pure tungsten, low-activation steel, pure vanadium and pure iron to be welded brightly, and the surface roughness Ra≤3.2μm;

[0039] 4) pickling the surfaces to be welded of pure tungsten, low-activation steel, pure vanadium foil and pure iron foil with dilute hydrochloric acid with a volume fraction of 5%, to remove residual oxides on the surface;

[0040] 5) Put the pickled pure tungsten, low-activation steel, pure vanadium foil and pure iron foil into acetone and alcohol for ultrasonic cleaning, respectively, for 20 minutes;

[0041] 6) Put the cleane...

Embodiment 2

[0045] Embodiment 2 Preparation of tungsten / titanium / iron / low activation steel joint

[0046]1) Process pure tungsten, pure titanium, pure iron and low activation steel into sizes of 30mm×30mm×3mm, 30mm×30mm×0.1mm, 30mm×30mm×0.4mm and 30mm×30mm×30mm respectively;

[0047] 2) Carry out vacuum softening annealing treatment on pure titanium foil and pure iron foil. -3 Pa;

[0048] 3) Use SiC sandpaper to polish the surface of pure tungsten, low-activation steel, pure titanium and pure iron to be welded brightly, and the surface roughness Ra≤3.2μm;

[0049] 4) pickling the surface to be welded of pure tungsten, low-activation steel, pure titanium foil and pure iron foil with dilute hydrochloric acid with a volume fraction of 5%, to remove residual oxides on the surface;

[0050] 5) Put the pickled pure tungsten, low-activation steel, pure titanium foil and pure iron foil into acetone and alcohol in sequence for ultrasonic cleaning, respectively, for 20 minutes;

[0051] 6) Put ...

Embodiment 3

[0054] Embodiment 3 Preparation of tungsten / vanadium / iron / low activation steel joint

[0055] 1) Process pure tungsten, pure vanadium, pure iron and low activation steel into sizes of 30mm×30mm×3mm, 30mm×30mm×0.3mm, 30mm×30mm×0.5mm and 30mm×30mm×30mm respectively;

[0056] 2) Carry out vacuum softening annealing treatment on pure vanadium foil and pure iron foil. -3 Pa;

[0057] 3) Use SiC sandpaper to polish the surface of pure tungsten, low-activation steel, pure vanadium and pure iron to be welded brightly, and the surface roughness Ra≤3.2μm;

[0058] 4) pickling the surfaces to be welded of pure tungsten, low-activation steel, pure vanadium foil and pure iron foil with dilute hydrochloric acid with a volume fraction of 5%, to remove residual oxides on the surface;

[0059] 5) Put the pickled pure tungsten, low-activation steel, pure vanadium foil and pure iron foil into acetone and alcohol for ultrasonic cleaning, respectively, for 20 minutes;

[0060] 6) Put the cleane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com