Water-based quenching liquid, preparation method thereof and application of water-based quenching liquid in quenching of elastic strip

A water-based quenching and clip technology, which is used in quenching agents, manufacturing tools, heat treatment equipment, etc., can solve the problems of difficulty in ensuring the hardness of the core of clips, increase the cost of environmental protection, and reduce the service life of clips. With the effect of extension, long service life and increased quenching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

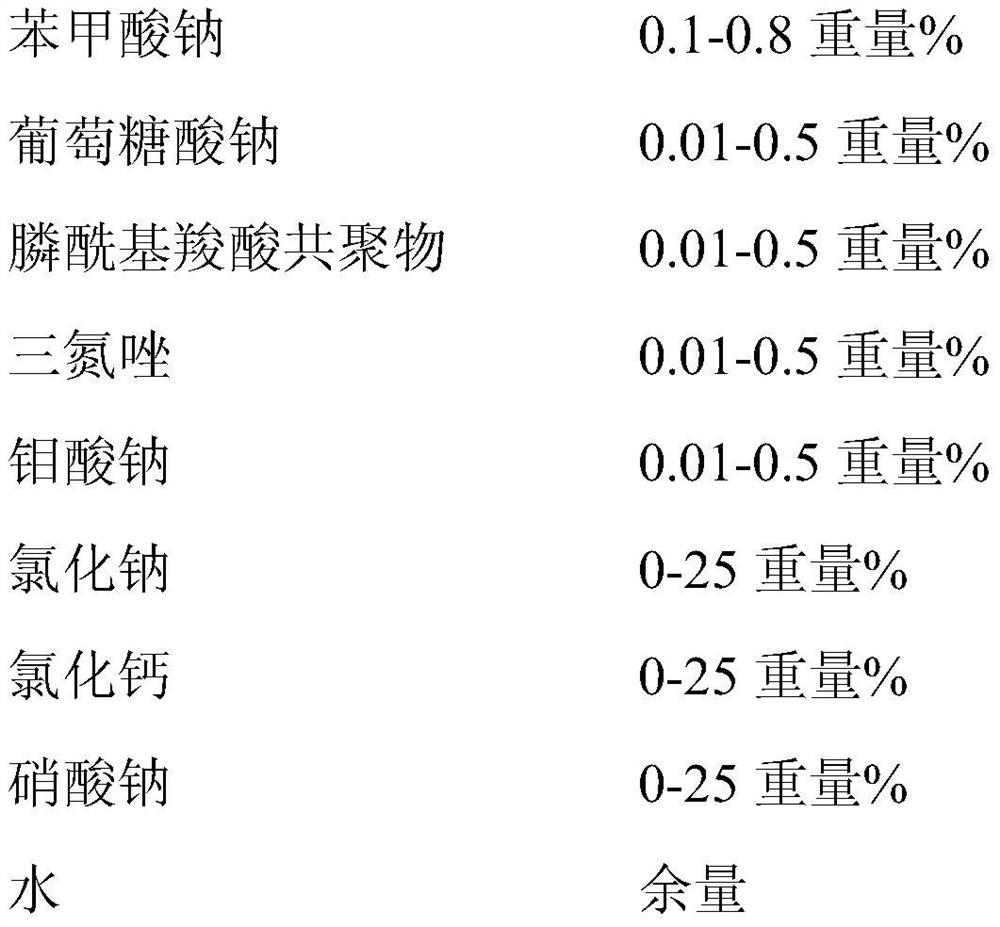

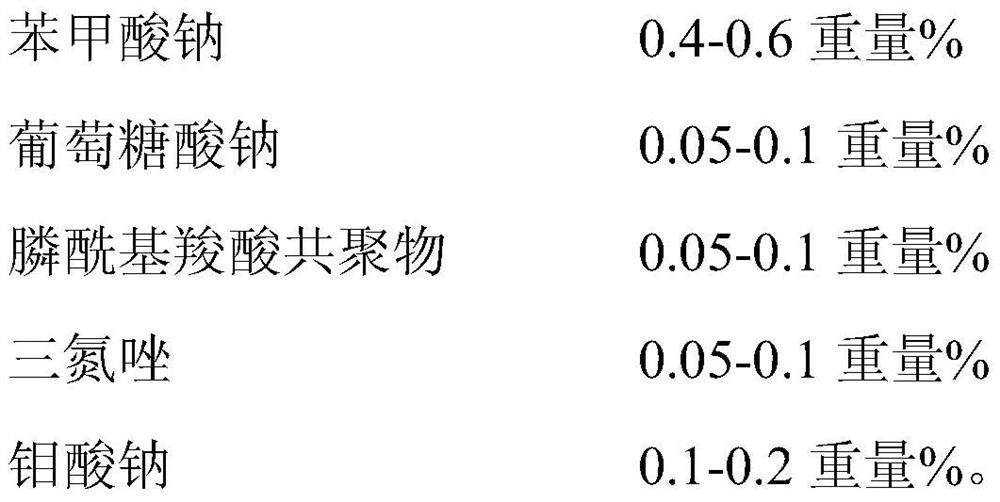

[0024] According to a preferred embodiment of the present invention, the water-based quenching liquid contains sodium chloride, and its concentration can be 0.01% by weight, 0.05% by weight, 0.1% by weight, 0.5% by weight, 1% by weight, 2% by weight, 3% by weight % by weight, 4% by weight, 5% by weight, 6% by weight, 7% by weight, 8% by weight, 9% by weight, 10% by weight, 15% by weight, 20% by weight, 25% by weight, preferably 3-8% by weight .

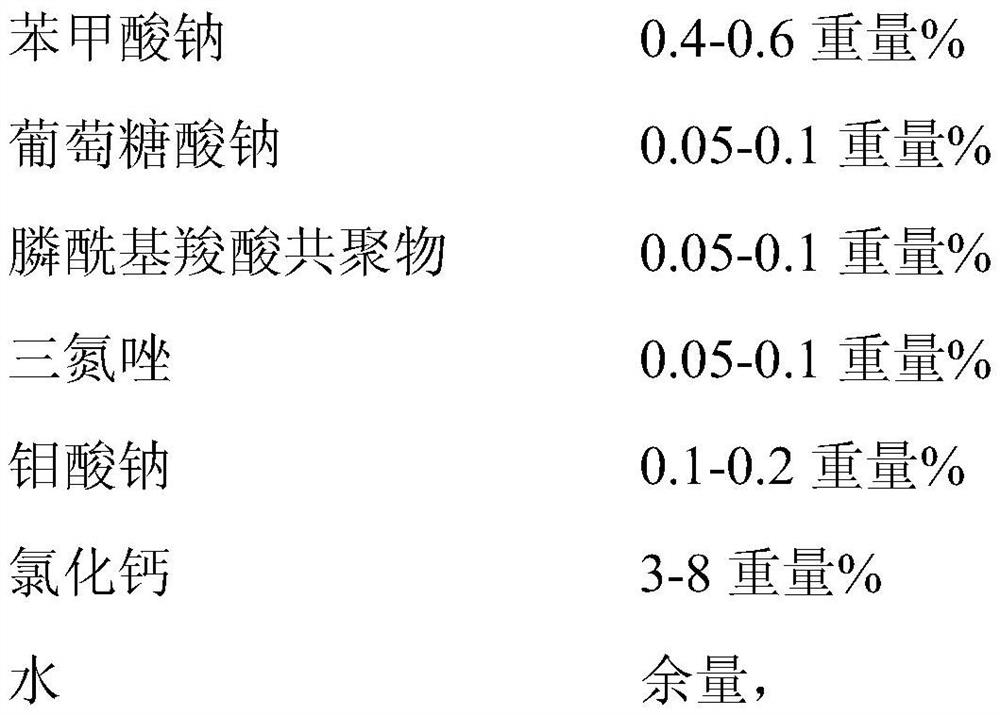

[0025] According to a preferred embodiment of the present invention, the water-based quenching liquid contains calcium chloride, and its concentration can be 0.01% by weight, 0.05% by weight, 0.1% by weight, 0.5% by weight, 1% by weight, 2% by weight, 3% by weight % by weight, 4% by weight, 5% by weight, 6% by weight, 7% by weight, 8% by weight, 9% by weight, 10% by weight, 15% by weight, 20% by weight, 25% by weight, preferably 3-8% by weight .

[0026] According to a preferred embodiment of the present invention, the water-based q...

Embodiment 1-3

[0060] Used to illustrate the water-based quenching liquid provided by the present invention and its preparation method

[0061] 1. Dissolve calcium chloride in deionized water and stir for 60 minutes to obtain the initial solution;

[0062] 2. Add sodium benzoate, sodium gluconate, and sodium molybdate to the mixed solution in step 1, and stir for 60 minutes;

[0063] 3. Heat the mixed solution in step 2 to 60°C, add phosphonocarboxylic acid copolymer (POCA, weight average molecular weight 4000), triazole, and stir for 60 minutes;

[0064] 4. Cool the mixed solution in step 3 to 25°C, and adjust the pH value by adding sodium hydroxide. After stirring for 30 minutes, filter the precipitate to obtain a water-based quenching solution. The concentration of each component is shown in Table 1.

[0065] Table 1

[0066] Example 1 Example 2 Example 3 Calcium chloride (weight%) 5 8 3 Sodium Benzoate (wt%) 0.5 0.05 0.1 Sodium gluconate (weight%) 0...

Embodiment 4

[0068] The preparation of the water-based quenching solution was carried out according to the method of Example 1, except that calcium chloride was not added, but replaced with an equivalent amount of sodium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com