Tube manufacturing method and apparatus for fixed diameter rolling

A manufacturing method and sizing technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as wrinkles on the inner surface of tubes, and achieve the effect of suppressing wrinkles, suppressing occurrence and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] One embodiment of the present invention will be described below with appropriate reference to the drawings.

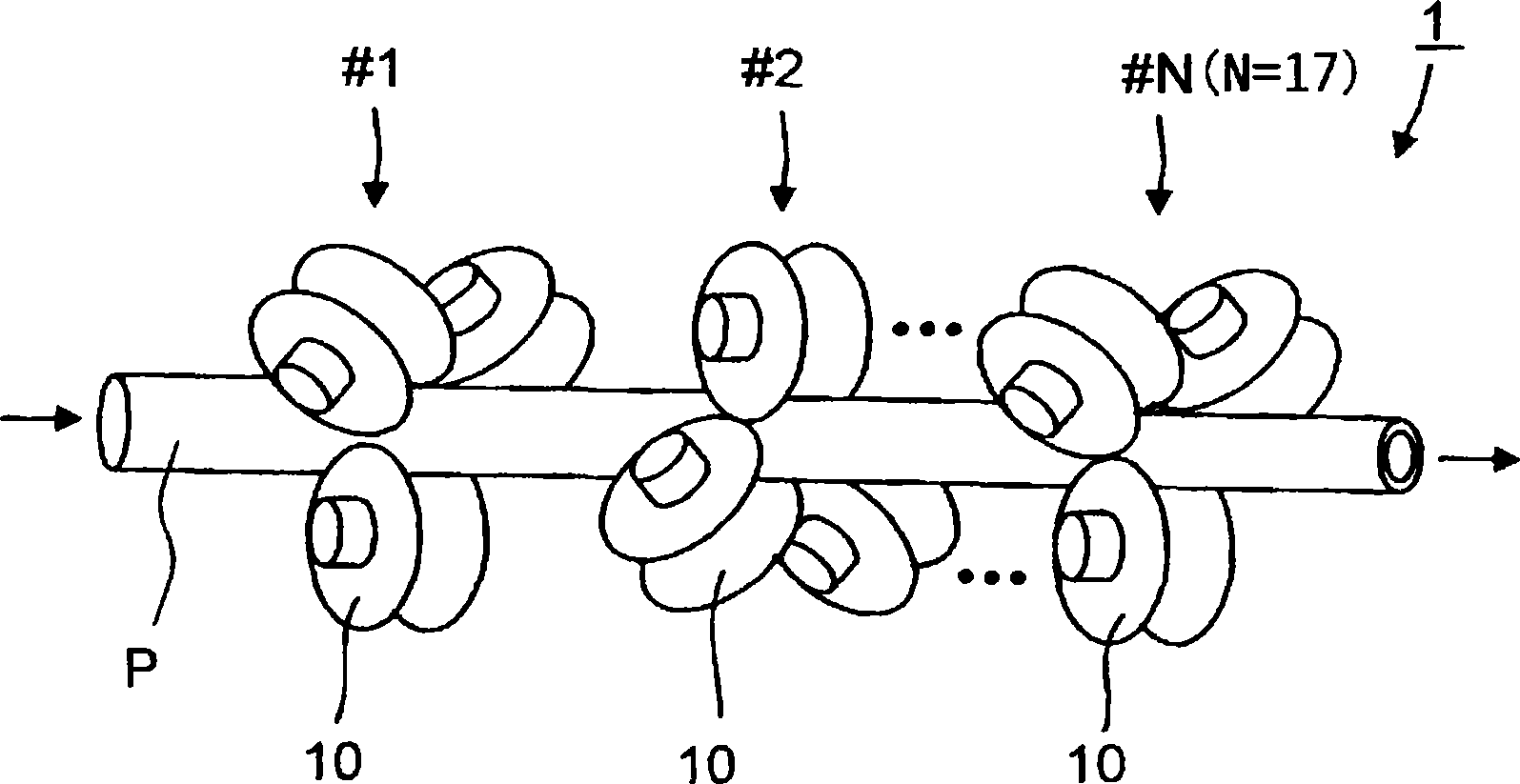

[0031] figure 1 It is a diagram schematically showing a 3-high sizing rolling apparatus to which a method for manufacturing a pipe according to an embodiment of the present invention is applied. Such as figure 1 As shown, in the sizing rolling device of this embodiment (in this embodiment, a tension reducing mill for hot sizing rolling) 1, in a plurality (N, in this embodiment, N= 17) Stands #1 to #N are respectively provided with three grooved rolls 10 with an included angle of 120° in the pressing direction, and the rolling directions of the rolls 10 are alternately arranged by staggering 60° between adjacent stands. The pipe P to be rolled is passed through the pass formed by the rolls of each stand, and sizing rolling is performed on the exit side of the final stand #N so that the outer diameter becomes a predetermined value. In addition, when the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com