Ion plating Ni-P nanometer laminated membrane and preparation method thereof

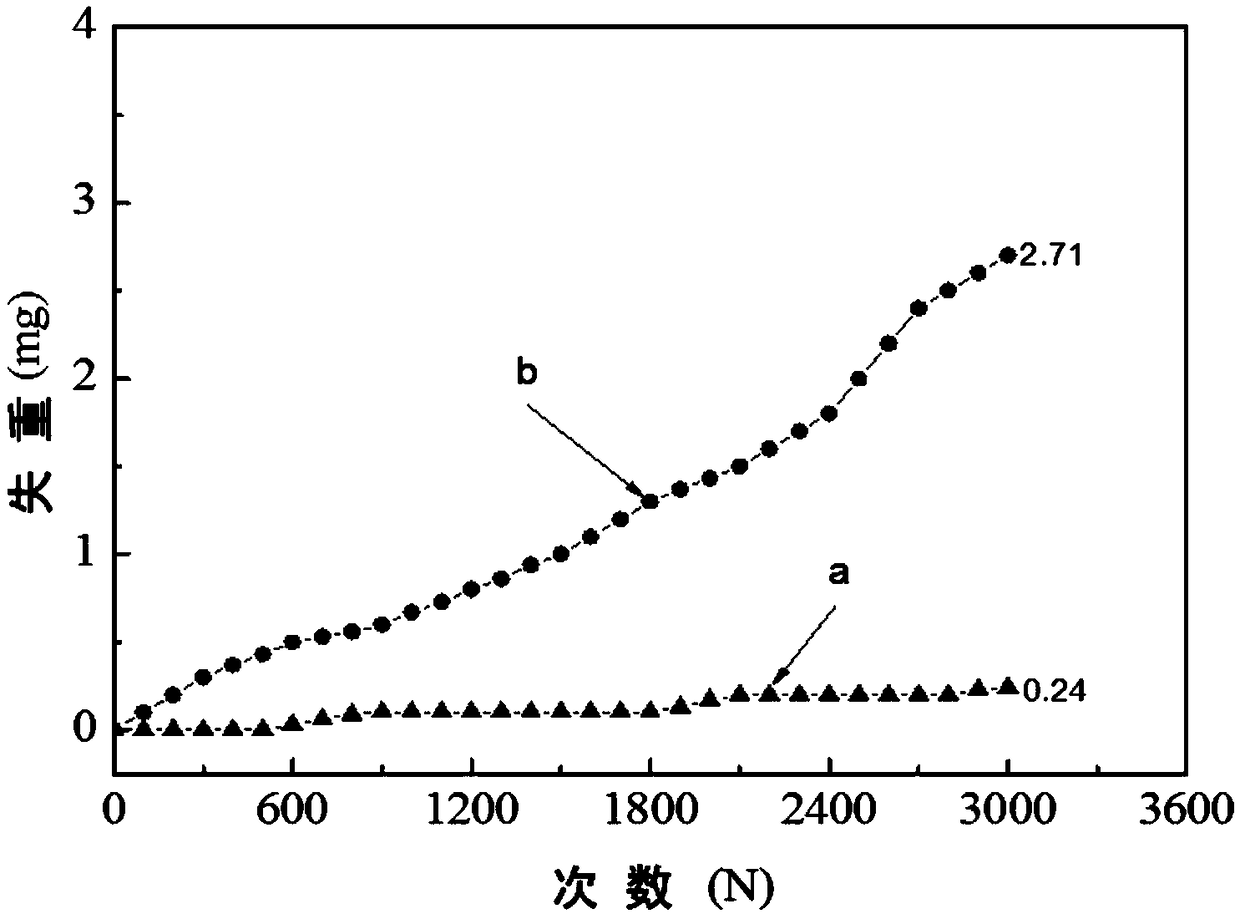

A technology of nano lamination and ion plating, applied in ion implantation plating, coating, sputtering plating, etc., can solve the problems of a large amount of waste liquid, non-compliance, and corrosion resistance to be improved, so as to improve corrosion resistance , avoid heterogeneous interface, reduce the effect of coating porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

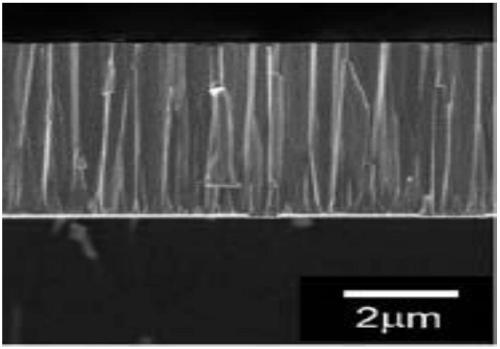

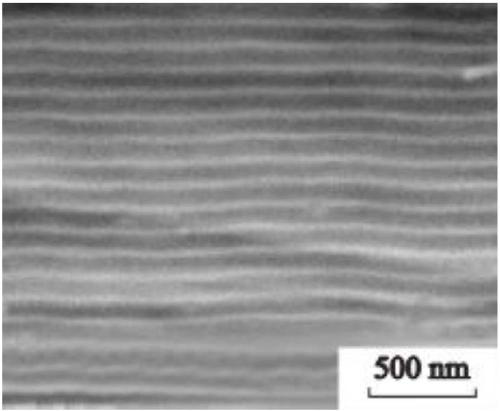

[0037] An ion-plated Ni-P nano-laminated film is a nano-laminated Ni-P film with a layered structure obtained by depositing a ferrous metal as a base material by ion-plating technology. The coating is composed of layered Ni-P film, the average thickness of each single layer is about 50nm, the total thickness of the coating is about 2.5μm, the self-corrosion potential is ≥-230mV, and the cross-sectional appearance is as follows: figure 2 shown.

[0038] The content of P in the nano lamination Ni-P film is 4at%, and the balance is Ni.

[0039] The preparation method of above-mentioned ion-plated Ni-P nano laminated film, comprises the following steps:

[0040] 1) Use the environmentally friendly detergent solution to remove the oil on the surface of the 304 stainless steel substrate material by high-pressure spraying, and then use superheated steam to completely remove the residual detergent solution on the surface of the substrate, so that the surface of the substrate can be ...

Embodiment 2

[0045] An ion-plated Ni-P nano-laminated film is a nano-laminated Ni-P film with a layered structure obtained by depositing a ferrous metal as a base material by ion-plating technology. The coating is composed of a layered Ni-P film, the average thickness of each single layer is about 120nm, the total thickness of the coating is about 80μm, and the self-corrosion potential is ≥-230mV.

[0046] The content of P in the nano lamination Ni-P film is 8 at%, and the balance is Ni.

[0047] The preparation method of above-mentioned ion-plated Ni-P nano laminated film, comprises the following steps:

[0048] 1) Use the environmentally friendly detergent solution to remove the oil on the surface of the 304 stainless steel substrate material by high-pressure spraying, and then use superheated steam to completely remove the residual detergent solution on the surface of the substrate, so that the surface of the substrate can be kept highly clean and has a certain activity;

[0049] 2) T...

Embodiment 3

[0053] An ion-plated Ni-P nano-laminated film is a nano-laminated Ni-P film with a layered structure obtained by depositing a ferrous metal as a base material by ion-plating technology. The coating is composed of a layered Ni-P film, the average thickness of each single layer is about 80nm, the total thickness of the coating is about 50μm, and the self-corrosion potential is ≥-230mV.

[0054] The content of P in the nano lamination Ni-P film is 6at%, and the balance is Ni.

[0055] The preparation method of above-mentioned ion-plated Ni-P nano laminated film, comprises the following steps:

[0056] 1) Use the environmentally friendly detergent solution to remove the oil on the surface of the 304 stainless steel substrate material by high-pressure spraying, and then use superheated steam to completely remove the residual detergent solution on the surface of the substrate, so that the surface of the substrate can be kept highly clean and has a certain activity;

[0057] 2) Tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com