4D printing crack-free special substrate made of titanium-nickel shape memory alloy and preparation method thereof

A memory alloy, crack-free technology, applied in the direction of additive processing, etc., can solve the problems of inability to prepare workpieces with complex shapes, affect the performance, and cracks are easy to occur on the titanium-nickel substrate, achieve high hardness and strength, and hinder grain growth , the effect of not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

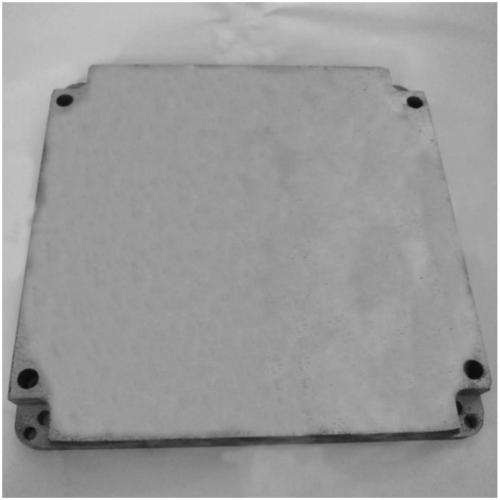

Image

Examples

Embodiment 1

[0028] The special substrate for 4D printing titanium-nickel shape memory alloy without cracks, the weight percentage of each component is as follows: Ni: 60%, Ti: 37%, Zr: 3%.

[0029] A method for preparing a crack-free 4D printed titanium-nickel shape memory alloy special substrate, comprising the following steps:

[0030] Mixing micron grade pure Ni powder, pure Ti powder and pure Zr powder, and adding 2wt% polyvinyl alcohol binder to fully mix;

[0031] Press the mixed NiTiZr powder according to the pressure of 400 tons;

[0032] The NiTiZr powder is sintered into a plate by conventional vacuum sintering method, the sintering parameters are: sintering temperature 1100°C, sintering time 4h, and the NiTiZr plate is processed into a special substrate for 4D printing titanium-nickel shape memory alloy.

[0033] The special substrate for 4D printing titanium-nickel shape memory alloy prepared by the above method has no cracks, a hardness of 280HV, and a tensile strength of 76...

Embodiment 2

[0035] A special substrate for 4D printing titanium-nickel shape memory alloy without cracks, the weight percentage of each component is as follows: Ni: 60%, Ti: 38%, Zr: 2%.

[0036] A method for preparing a crack-free 4D printed titanium-nickel shape memory alloy special substrate, comprising the following steps:

[0037] Mix micron grade pure Ni powder, pure Ti powder and pure Zr powder, and add 1wt% polyvinyl alcohol binder to fully mix;

[0038] The mixed NiTiZr powder is pressed into shape according to a pressure of 390 tons;

[0039] The NiTiZr powder is sintered into a plate by conventional vacuum sintering method. The sintering parameters are: sintering temperature 1080°C, sintering time 3h, and the NiTiZr plate is processed into a special substrate for 4D printing titanium-nickel shape memory alloy.

[0040] The special substrate for 4D printing titanium-nickel shape memory alloy prepared by the above method has no cracks, a hardness of 290HV, and a tensile strength...

Embodiment 3

[0042] A special substrate for 4D printing titanium-nickel shape memory alloy without cracks, the weight percentage of each component is as follows: Ni: 60%, Ti: 39%, Zr: 1%.

[0043] A method for preparing a crack-free 4D printed titanium-nickel shape memory alloy special substrate, comprising the following steps:

[0044] Mix micron grade pure Ni powder, pure Ti powder and pure Zr powder, and add 3wt% polyvinyl alcohol binder to fully mix;

[0045] Press the mixed NiTiZr powder according to the pressure of 380 tons;

[0046] The NiTiZr powder is sintered into a plate by conventional vacuum sintering method, the sintering parameters are: sintering temperature 1060°C, sintering time 2h, and the NiTiZr plate is processed into a special substrate for 4D printing titanium-nickel shape memory alloy.

[0047] The special substrate for 4D printing titanium-nickel shape memory alloy prepared by the above method has no cracks, a hardness of 295HV, and a tensile strength of 775MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com