Method for making quench hardening layer of cold roll barrel

A technology of cold-rolled work rolls and manufacturing methods, which is applied in the field of heat treatment, and can solve problems such as subsurface overheating, insufficient heating depth, and insufficient relaxation of the transition layer, and achieve the effects of delaying roll wear and prolonging roll changing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

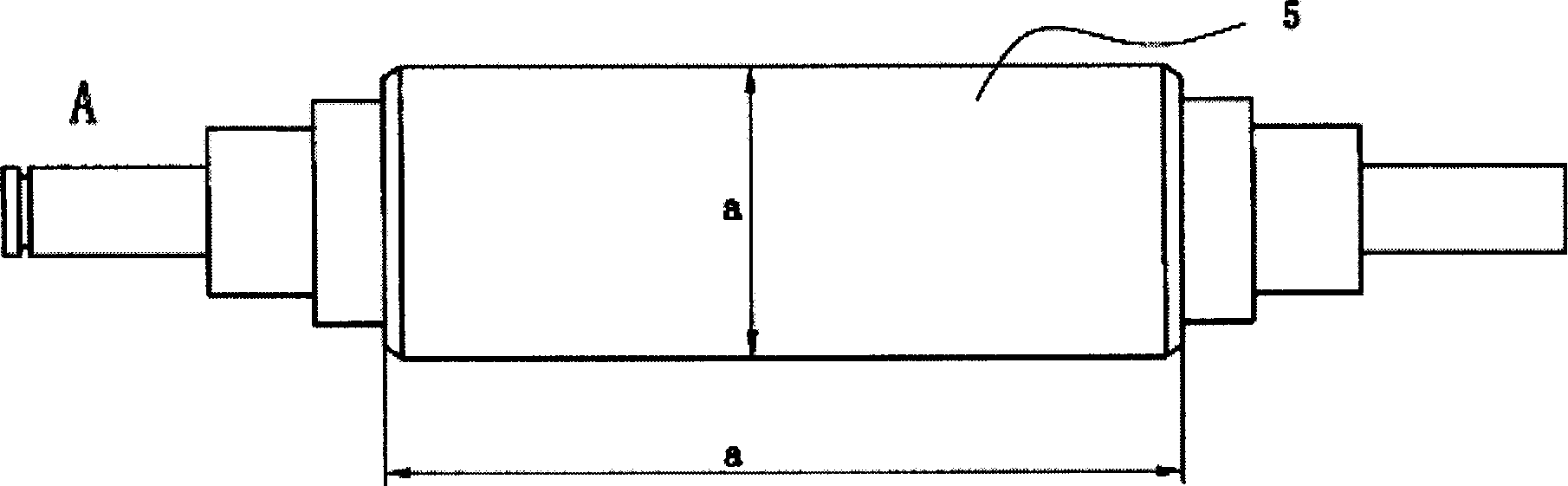

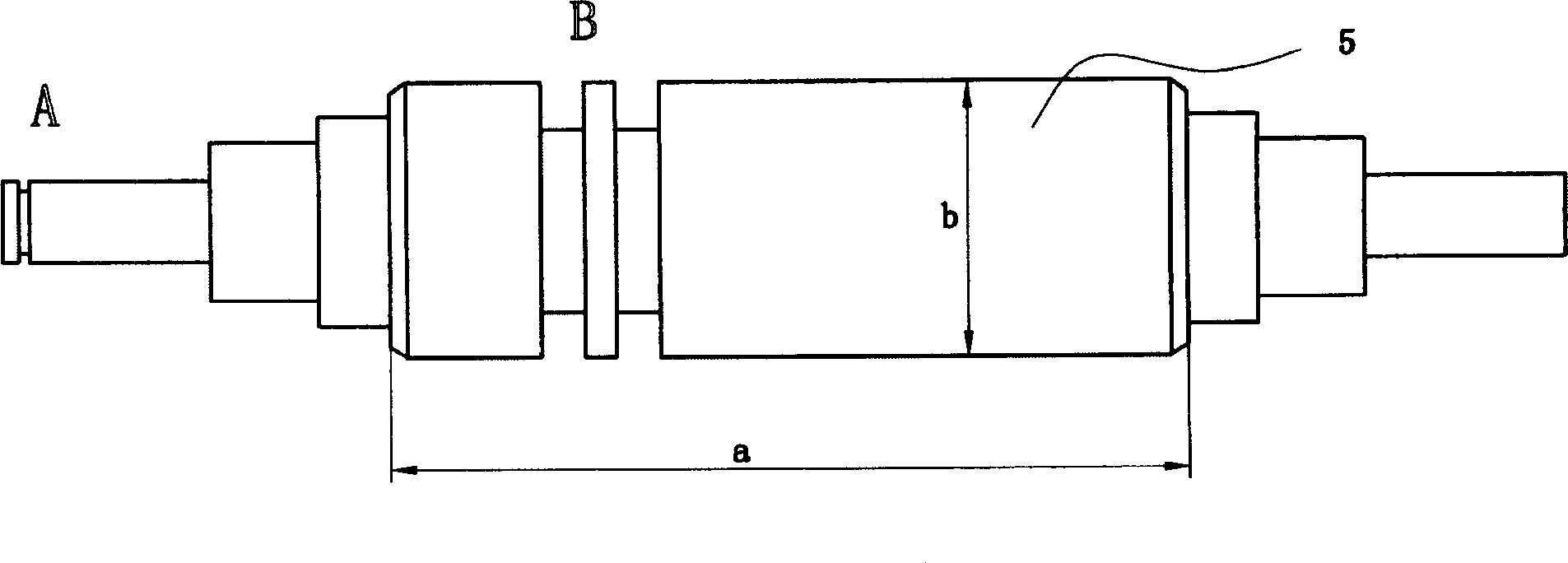

[0039] This embodiment adopts the cold-rolled work roll 5 roll blank obtained after smelting, electroslag remelting, roll blank forging, spheroidizing hydrogen expansion treatment, machining, quenching and tempering and other processes in the process of manufacturing cold-rolled work roll 5 It is a test roll, whose shape is shown in figure 1 , the length a of the roll body is 2030mm, the diameter b of the roll body is 520mm, and the end A is the lifting end of the roll during induction electric heating. The chemical composition of the materials used is shown in Table 1.

[0040] C

Si

mn

P

S

Cr

Ni

Mo

V

the rest is

Fe and

inevitable

Free of miscellaneous

quality

0.82

~0.90

0.30

~0.55

0.20

~0.50

≤

0.020

≤

0.015

4.90

~5.40

0.30

~0.50

0.20

~0.40

0.10 ...

Embodiment 2

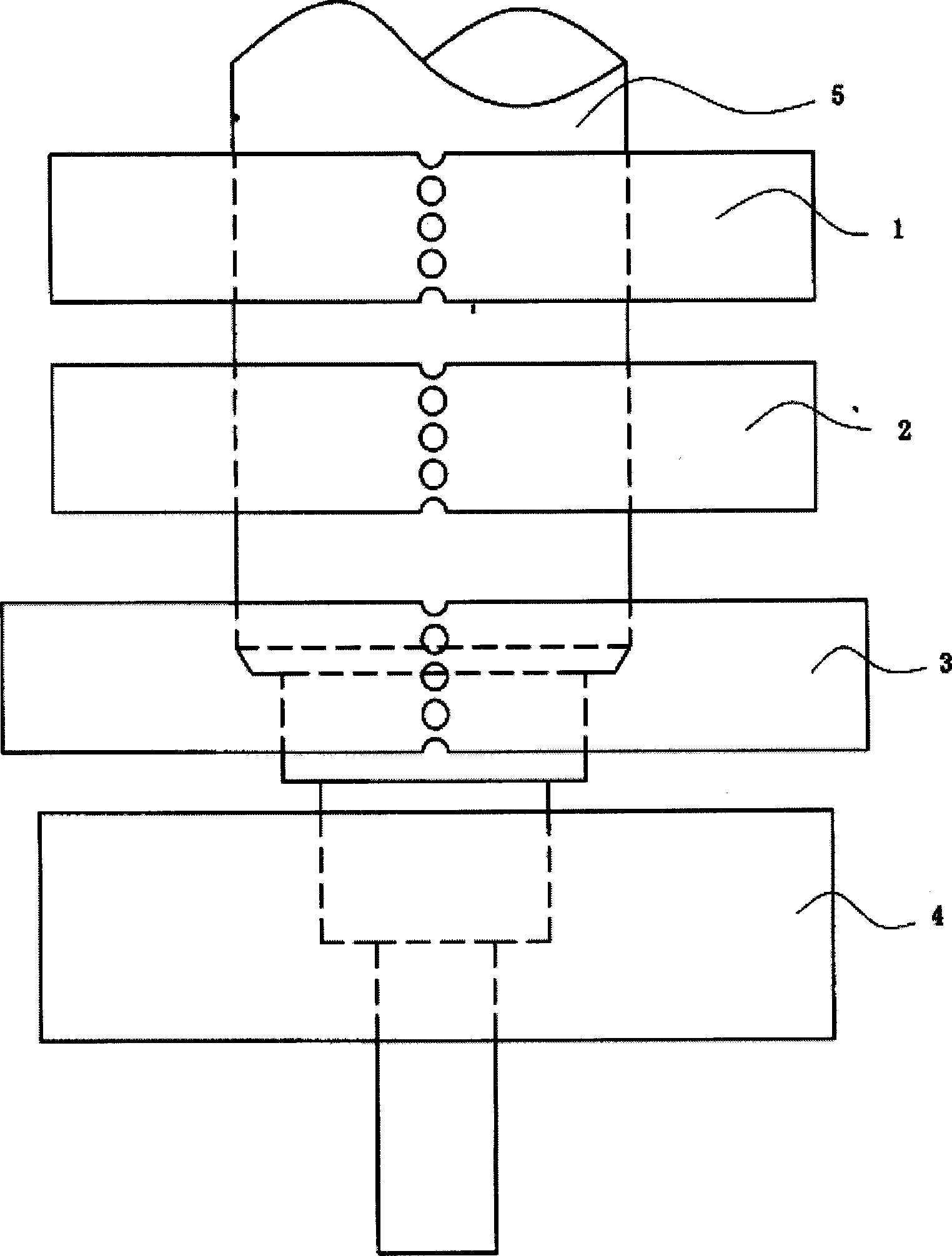

[0044] All the other are identical with embodiment 1, and difference is: in the double-frequency three-inductor machine tool, the horizontal spacing of roll body and the first industrial frequency inductor 1 is 37mm, and the horizontal spacing of the second industrial frequency inductor 2 can be 48mm, and the horizontal distance between the intermediate frequency sensor 3 is 50mm; the vertical distance between the first power frequency sensor 1 and the second power frequency sensor 2 is 37mm, and the vertical distance between the second power frequency sensor 2 and the intermediate frequency sensor 3 is 37mm, the vertical distance between the intermediate frequency sensor 3 and the sprinkler 4 is 37mm; after adjusting the relative position between the roll and the three sensors and the sprinkler 4, make the roll rotate at a speed of 200rad / min on one side of the machine tool , while vertically descending at a speed of 0.9mm / s; when the lower edge of the roll body stretches into...

Embodiment 3

[0047]The rest are the same as in Embodiment 1, except that in the dual-frequency three-inductor machine tool, the horizontal distance between the roll body and the first power frequency sensor 1 is 62mm, and the horizontal distance between the roll body and the second power frequency sensor 2 is 75mm , The horizontal distance from the intermediate frequency sensor 3 is 75mm; the vertical distance between the first power frequency sensor 1 and the second power frequency sensor 2 is 65mm, and the vertical distance between the second power frequency sensor 2 and the intermediate frequency sensor 3 is 65mm 1. The vertical distance between the intermediate frequency inductor 3 and the sprinkler 4 is 65mm; after adjusting the relative position between the roll and the three inductors and the sprinkler 4, the roll is rotated at a speed of 360rad / min in the lathe. One side drops vertically at a speed of 1.5mm / s; when the lower edge of the roll body extends into the first power frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com