Nanocrystalline complex phase neodymium iron boron permanent magnet texturing enhancement preparation method

A NdFeB, permanent magnet technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of uneven distribution of low melting point grain boundary phase, short deformation time, flaky crystal growth, etc. , to inhibit the formation and expansion of cracks, improve densification and magnetic properties, and enhance the texture of hard magnetic phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

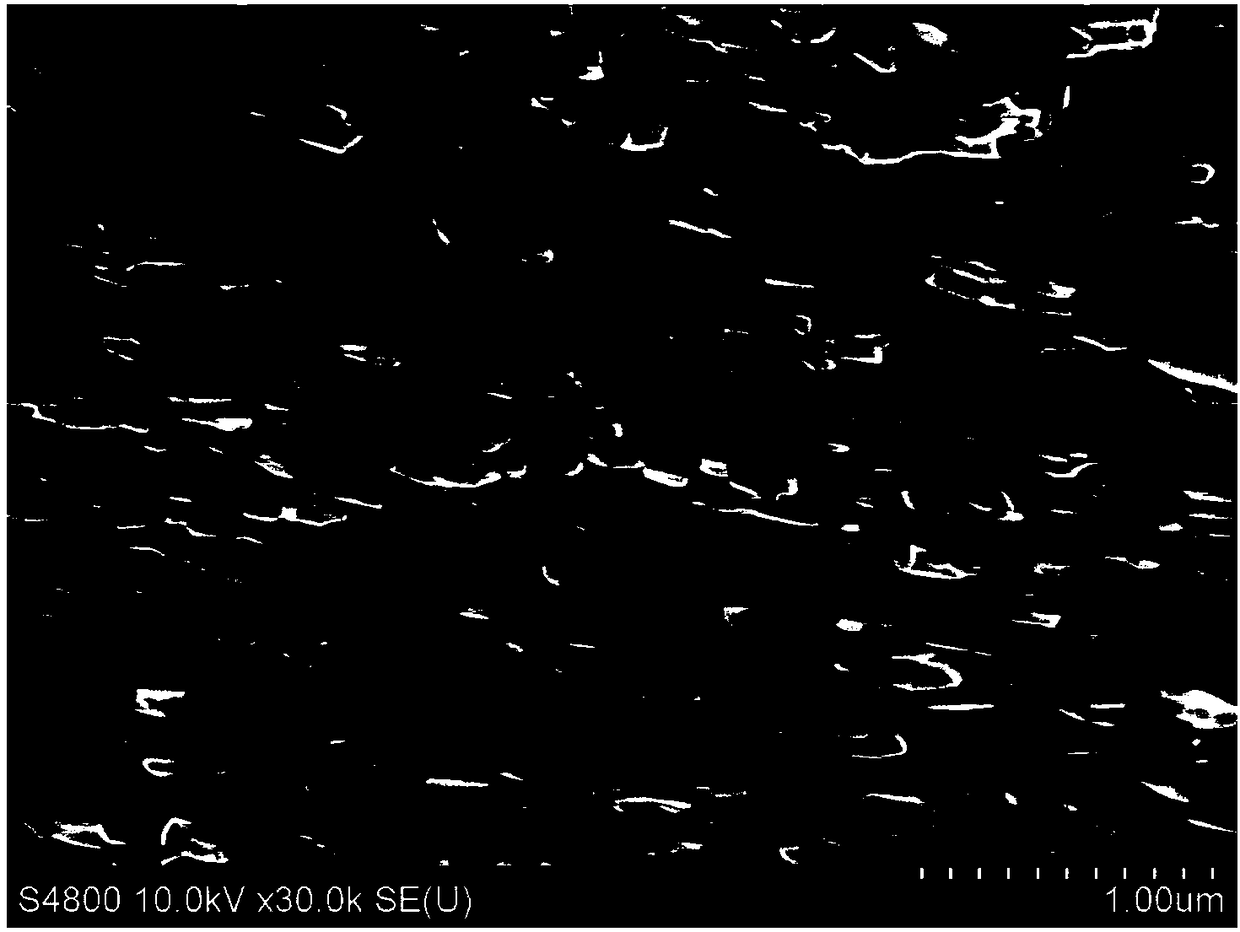

[0022] In this embodiment, the raw material is commercial rare-earth-poor dual-phase magnetic powder NdFeB (15-7) purchased from Magnequench Magnetics (Tianjin) Co., Ltd., and the raw material and low melting point alloy powder Nd 70 Cu 30 mixing, the doping amount of the Nd-Cu alloy powder accounts for 8% of the mass of the raw material to obtain the doped raw material.

[0023] The preparation method of this Nd-Cu alloy powder is as follows:

[0024] (1) According to the composition of NdCu alloy, Nd is obtained by vacuum induction melting 70 Cu 30 alloy ingot;

[0025] (2) Broken the Nd under the protection of argon 70 Cu 30 Alloy ingots are ground and sieved to obtain NdCu alloy powders with a particle size below 90um;

[0026] Using this doping raw material, the anisotropic Nd 2 Fe 14 B complex phase permanent magnet block material, as follows:

[0027] (1) Hot pressing process: put the quantitative amount of the doped raw material into the cemented carbide mold,...

Embodiment 2

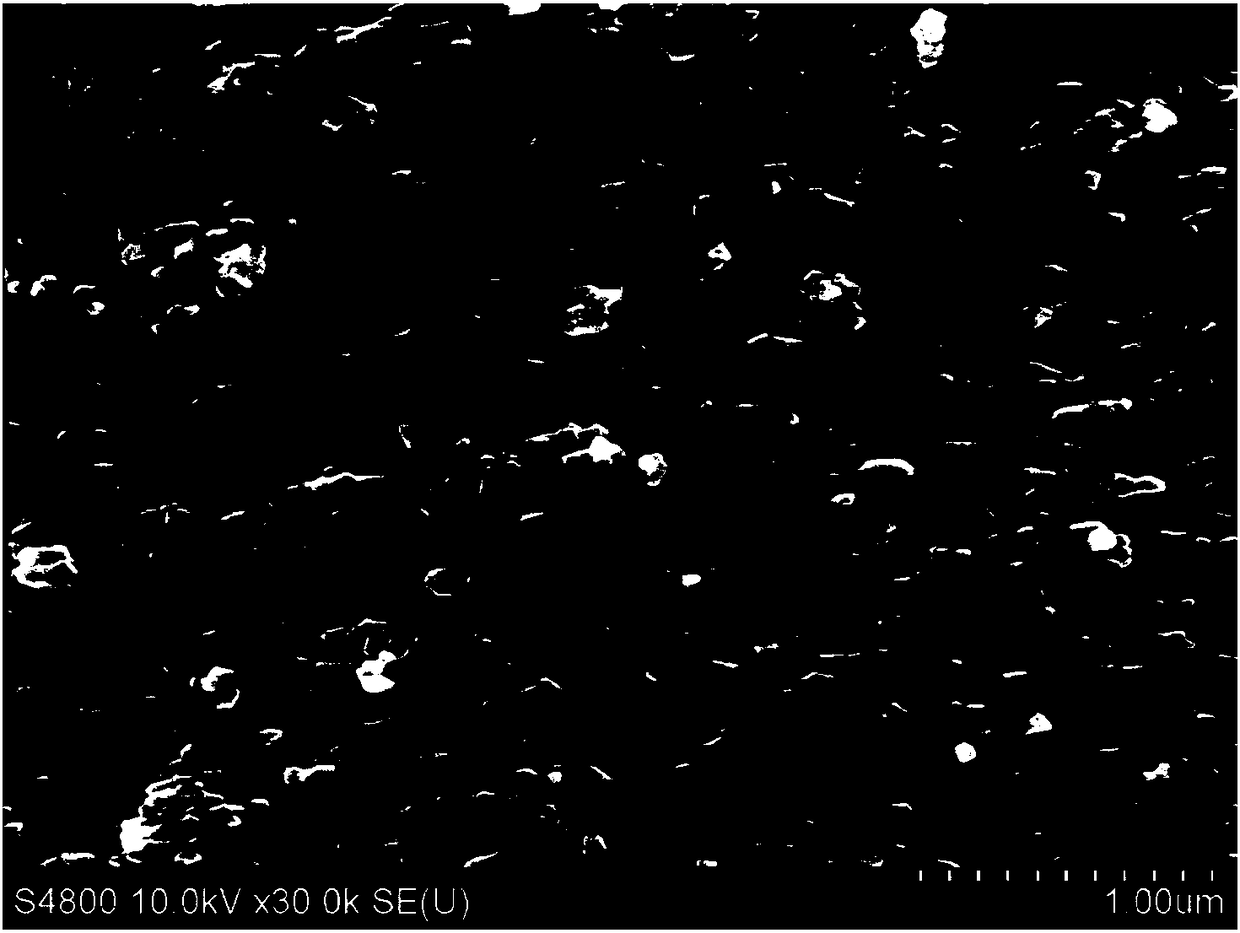

[0030] In this embodiment, the same doping raw materials as in Embodiment 1 are used.

[0031] Using this doping raw material, the anisotropic Nd 2 Fe 14 B complex phase permanent magnet block material, as follows:

[0032] (1) is exactly the same as the step (1) of embodiment 2;

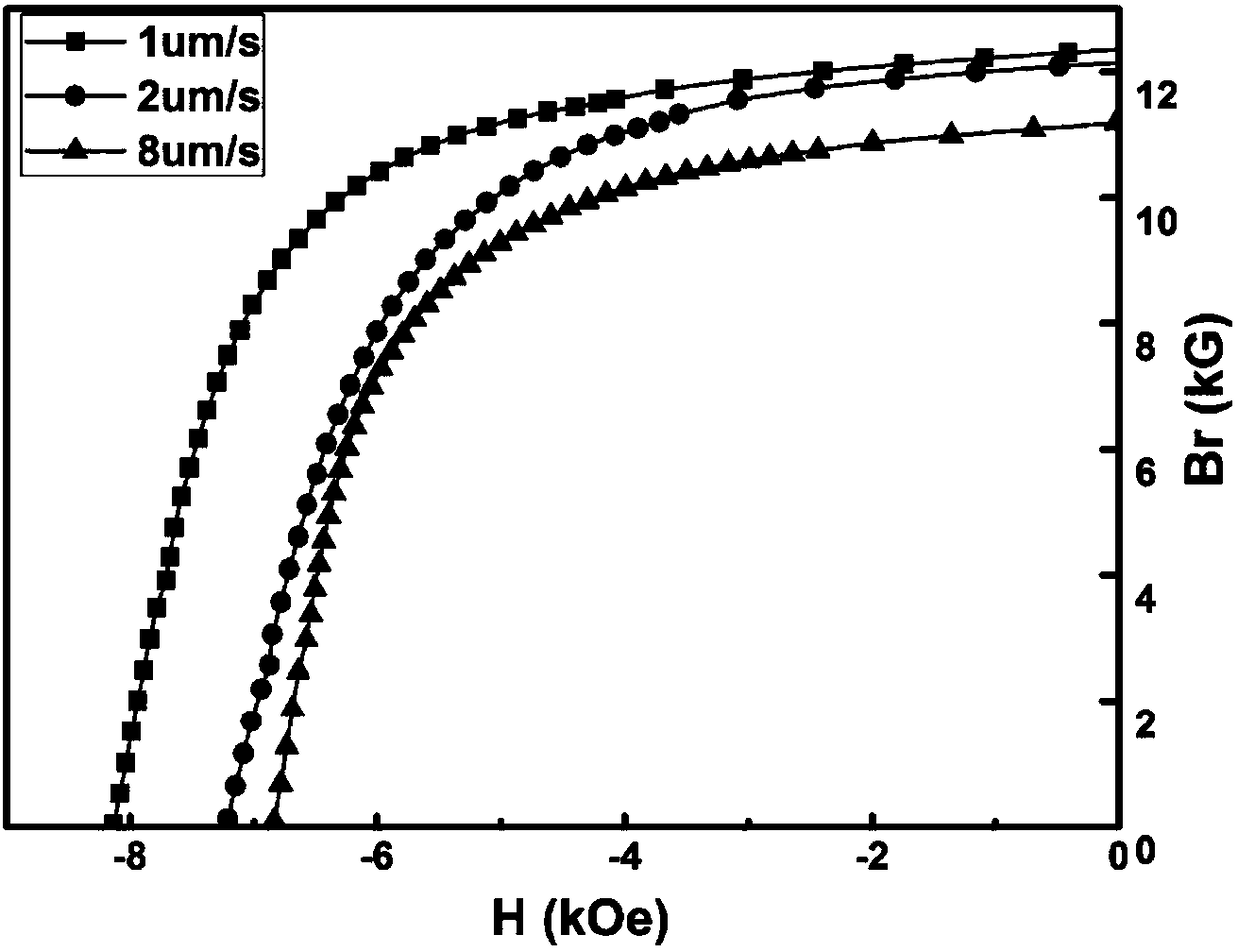

[0033] (2) It is basically the same as step (2) of Example 2, the only difference is that the deformation rate along the pressure direction v=2um / s is controlled under the condition of 600°C to carry out hot pressing deformation to the predetermined size, and the double Composite permanent magnet block material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com