Process for producing compact silicon/silicon carbide coating of optics reflection mirror

A technology of silicon carbide coatings and mirrors, which is applied in optics, coatings, optical components, etc., can solve the problems of surface roughness difficult to achieve high-resolution mirrors, SiC materials are difficult to complete, and low bonding strength, etc., to achieve shortening The effect of short preparation cycle and processing cycle and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The pre-coating formula is 40wt% of silicon powder, 15wt% of silicon carbide powder, 35wt% of carbon powder and 10wt% of polyvinyl alcohol, then add water ball mill with the same weight as the total weight of the above formula and mix it into mud, and then use the method of manual brushing Coating the surface of the mirror substrate preform made of C / C material to obtain a pre-coating, and then sintering the pre-coated C / C preform in a vacuum sintering furnace, process parameters: in the furnace The vacuum degree is less than 500Pa, the sintering temperature is 1600°C, and the temperature is kept for 4 hours to obtain a product coated with a dense silicon / silicon carbide coating (Si / SiC).

Embodiment 2

[0020] The pre-coating formula is 35wt% of silicon powder, 10wt% of silicon carbide powder, 45wt% of carbon powder and 10wt% of phenolic resin, and then add acetone ball mill with the same weight as the total weight of the above formula to make a slurry, and then make it on the C / SiC material The surface of the reflector substrate prefabricated part is brushed to obtain a precoat, and then placed in a vacuum sintering furnace for reaction to obtain a product coated with a dense silicon / silicon carbide coating (Si / SiC), and the sintering process parameters are the same as in Example 1 .

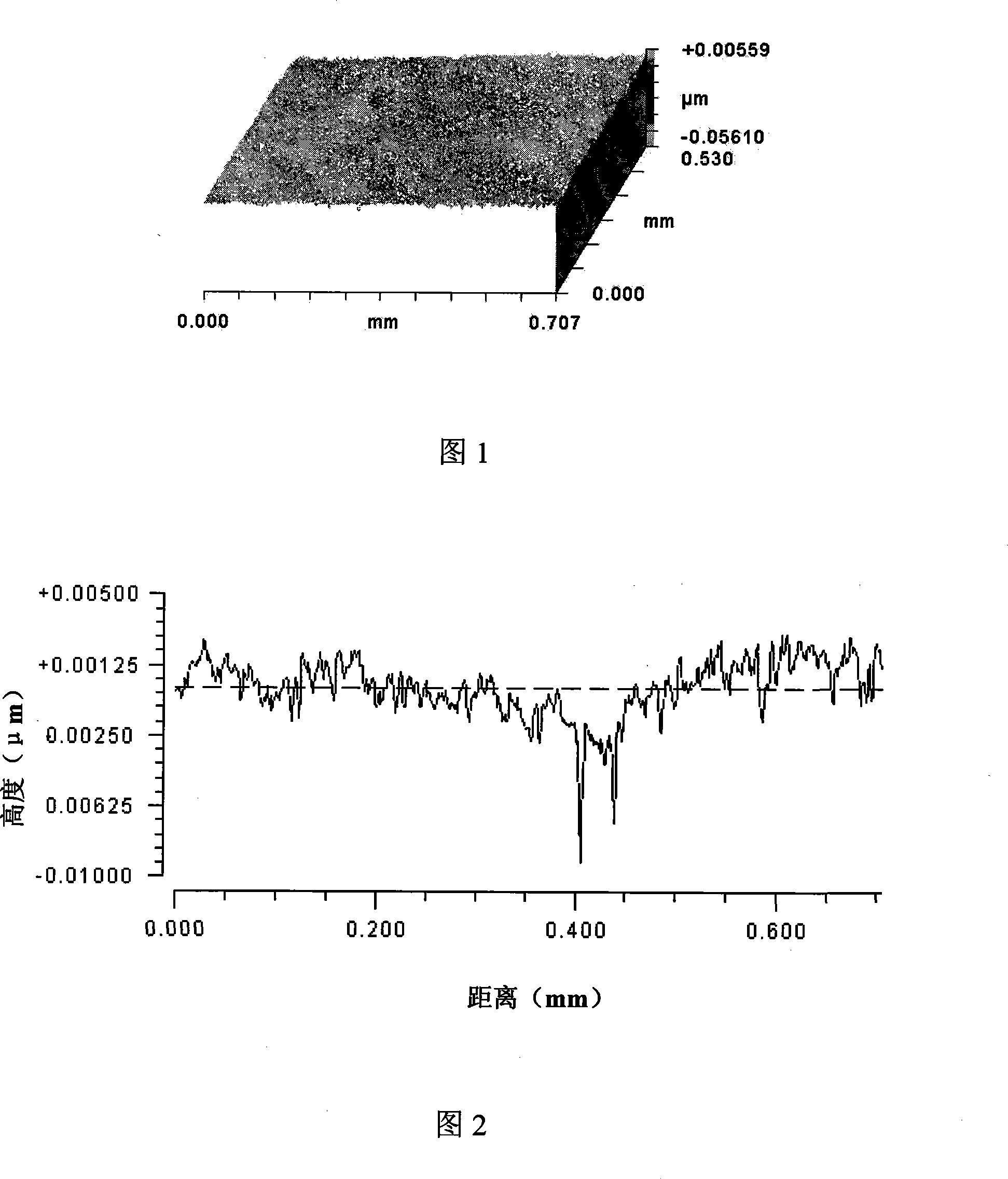

[0021] It can be seen from Figure 1 and Figure 2 that the surface roughness of the reaction sintered Si / SiC coating after polishing is less than 1.5nm, which meets the optical application requirements of the mirror.

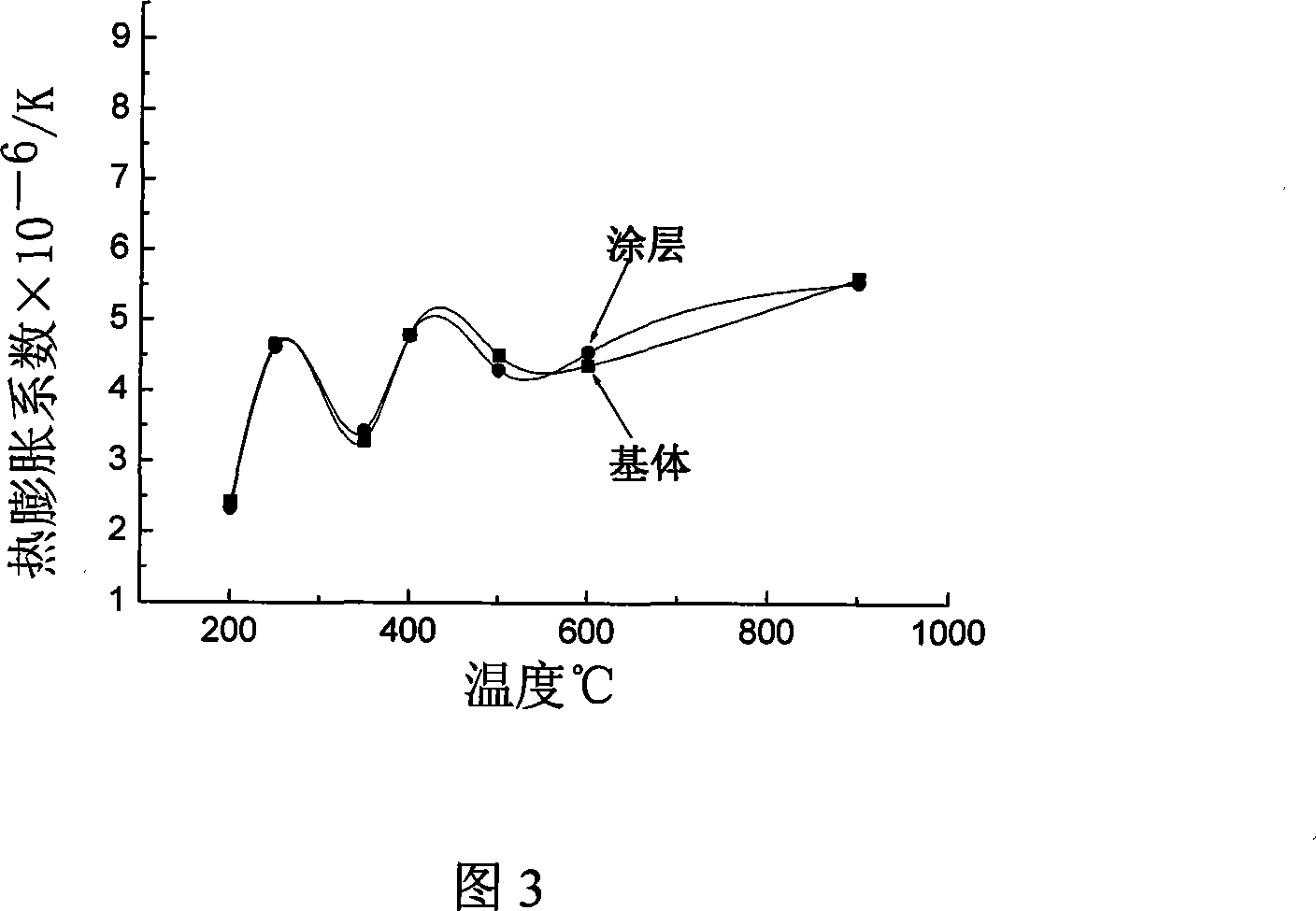

[0022] From the comparison of the thermal expansion coefficients of the reaction sintered Si / SiC coating and the C / SiC substrate shown in Figure 3, it can be seen that the therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com