N-type bismuth telluride-based room-temperature thermoelectric material and preparation method thereof

A technology of bismuth telluride-based chamber and electrical material, which is applied in the directions of thermoelectric device junction lead-out material, thermoelectric device manufacturing/processing, etc., can solve the problems of low device service life and yield, mismatch of application temperature range, etc. Achieve the effect of matching mechanical mechanics, improving service life and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

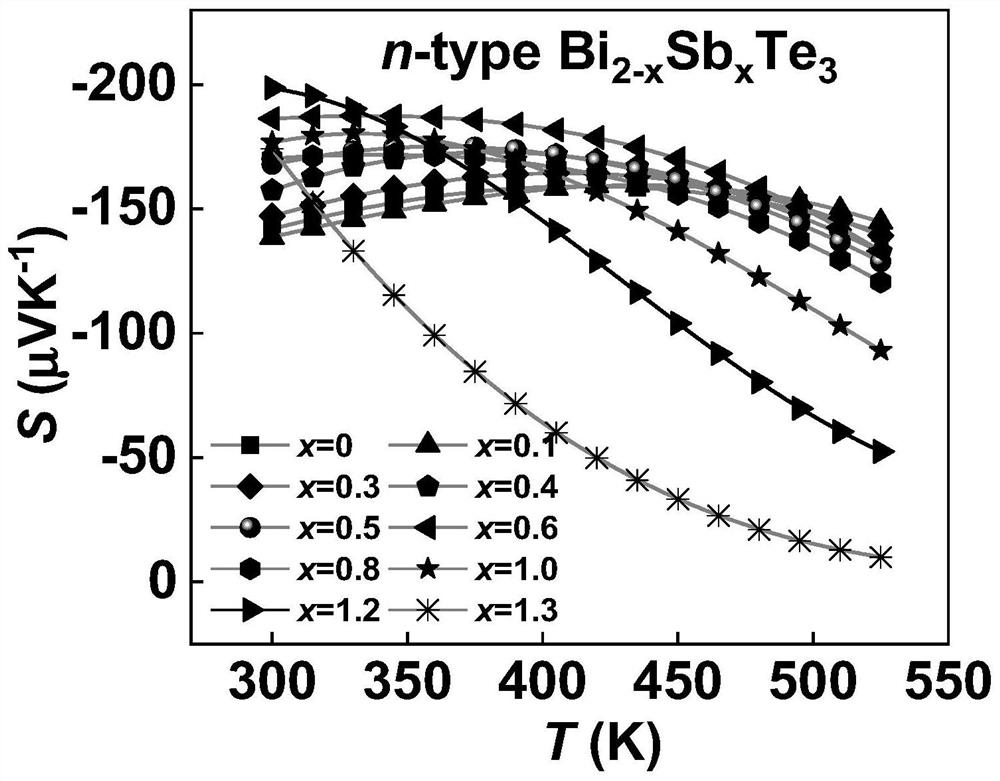

[0069] n-type Bi 2-x Sb x Te 3 Preparation of room temperature thermoelectric materials

[0070] According to the chemical formula Bi 2-x Sb x Te 3 The stoichiometric ratio of each element in the formula is to weigh the corresponding mass Bi Metal block, Sb metal block, Te metal block. Then the Sb metal block is put into the quartz tube, the Te metal block is put into the quartz tube, and finally the Bi metal block is put into the quartz tube, vacuumized and then sealed with a hydrogen flame, then it is vertical (quartz tube From bottom to top, Sb metal block, Te metal block, Bi metal block) were placed in a high-temperature box-type resistance furnace, and the temperature was gradually raised from room temperature to 650 °C at a rate of 2 °C / min, kept for 2 hours, and then heated at 4 °C The heating rate is raised to 900°C for 10 hours, and the alloy ingot is obtained after cooling. Then alloy ingots, 1 steel ball with a diameter of 15mm, 3 steel balls with a diameter...

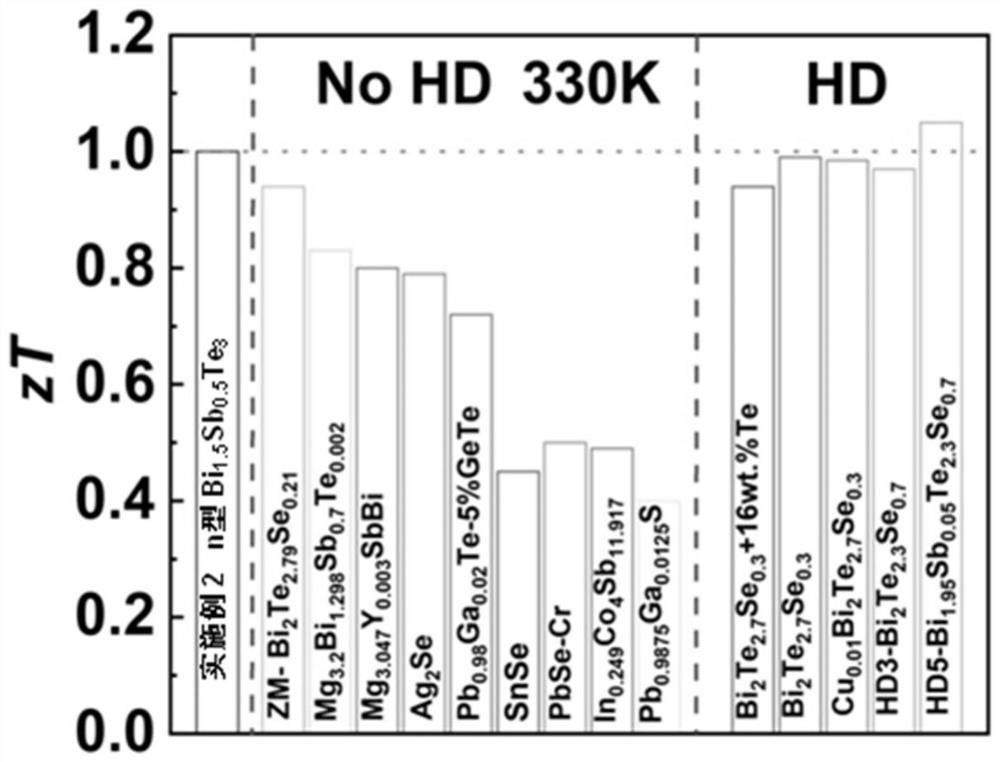

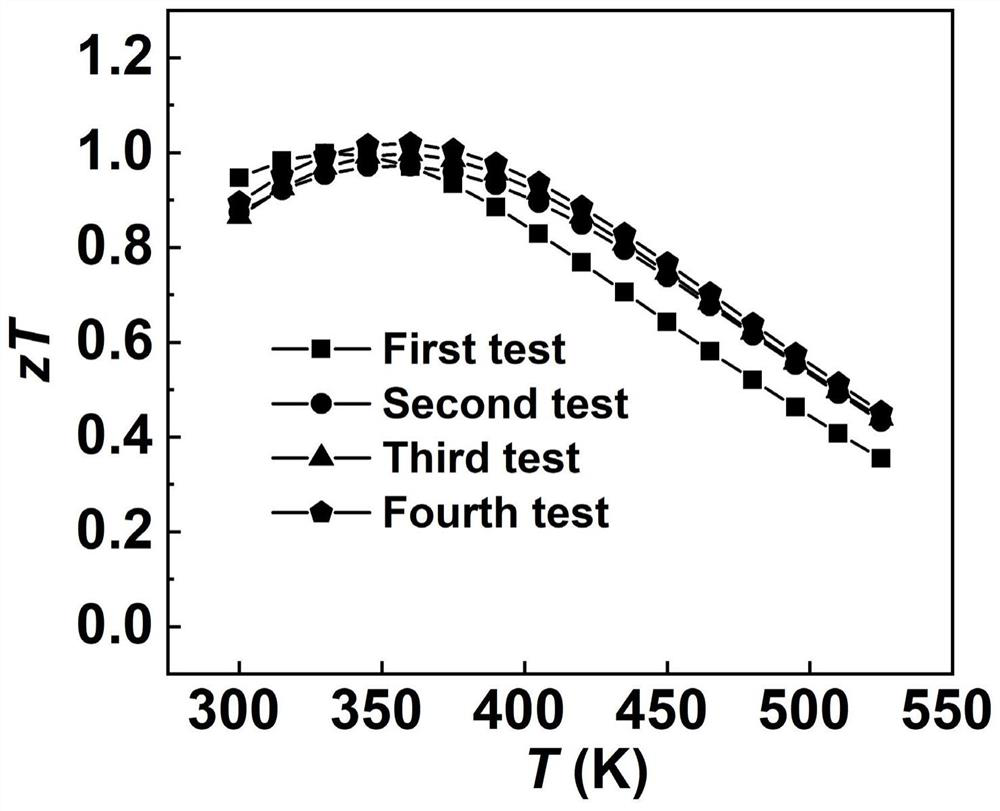

Embodiment 2

[0072] n-type Bi 1.5 Sb 0.5 Te 3 Preparation of room temperature thermoelectric materials

[0073] According to the chemical formula Bi 2-x Sb x Te 3 The stoichiometric ratio of each element is to weigh the corresponding mass of Bi metal block, Sb metal block and Te metal block according to the molar ratio of 1.5:0.5:3. Then the Sb metal block is put into the quartz tube, the Te metal block is put into the quartz tube, and finally the Bi metal block is put into the quartz tube, vacuumized and then sealed with a hydrogen flame, then it is vertical (quartz tube From bottom to top, Sb metal block, Te metal block, Bi metal block) were placed in a high-temperature box-type resistance furnace, and the temperature was gradually raised from room temperature to 650 °C at a rate of 2 °C / min, kept for 2 hours, and then heated at 4 °C The heating rate is raised to 900°C for 10 hours, and the alloy ingot is obtained after cooling. Then alloy ingots, 1 steel ball with a diameter of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com