Preparation method of high-dispersion graphene-ruthenium oxide nano composite material

A nanocomposite material and graphene technology, applied in the field of electrochemistry, can solve problems such as insufficient performance advantages, low reactivity, and unfriendly environment, and achieve the effects of improving electrochemical activity, simplifying preparation methods, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of graphene-ruthenium oxide nanocomposite material, comprising the following steps:

[0028] (1) Place citric acid and histidine in a beaker at a molar ratio of 1:1, react at 180° C. to obtain graphene quantum dots, and disperse graphene quantum dots in deionized water to obtain graphene quantum dot aqueous solution;

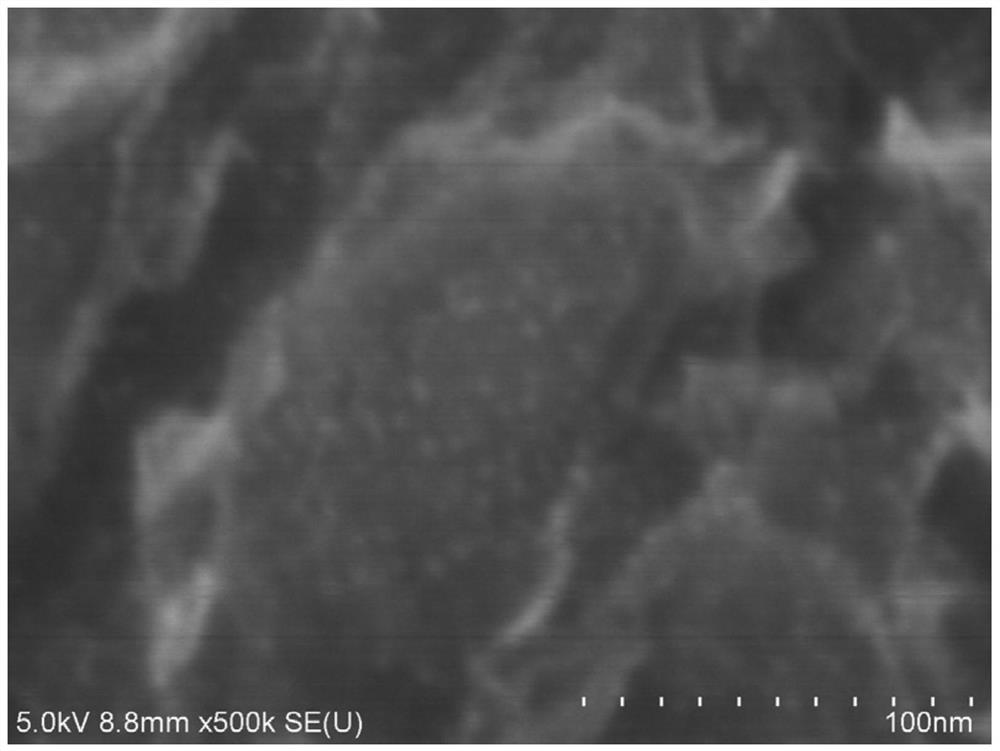

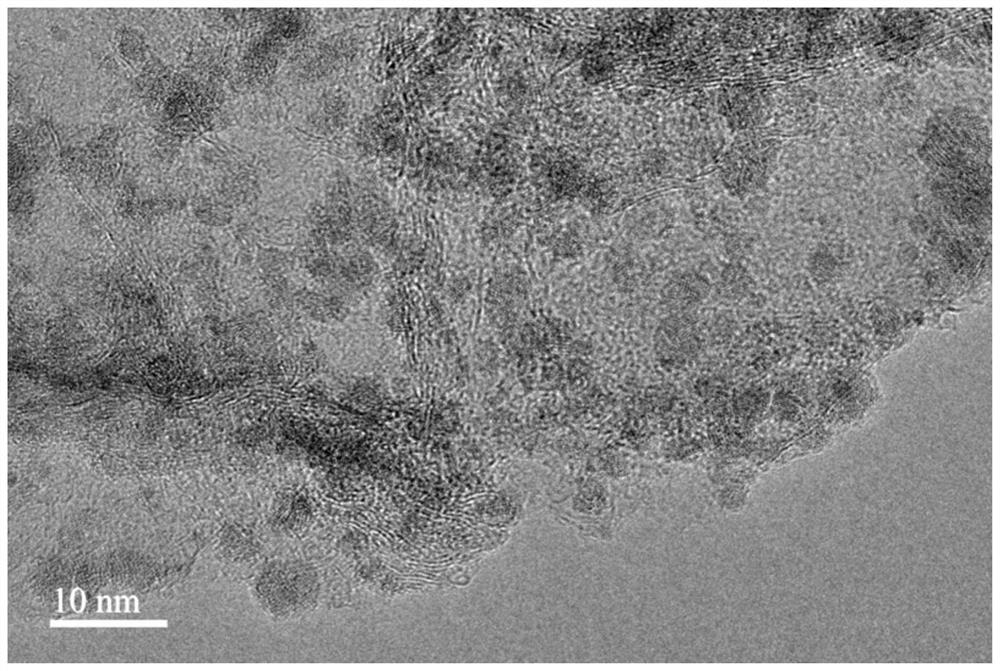

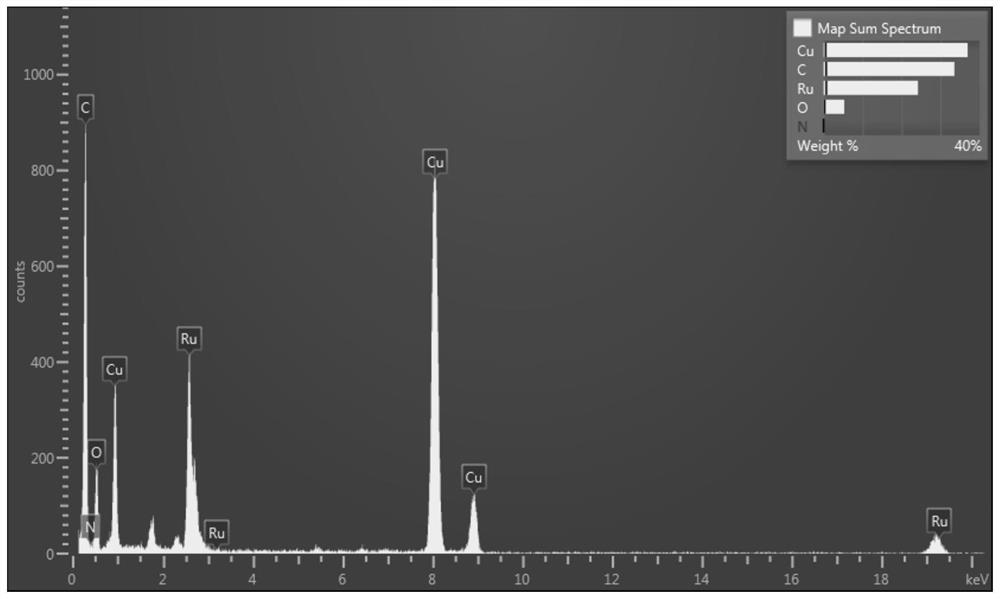

[0029] (2) graphene oxide is dispersed in deionized water to obtain an aqueous solution, and the graphene quantum dot aqueous solution prepared in step (1) is added under stirring, and the pH is adjusted to neutrality to obtain a compound, and the ruthenium chloride solution is added dropwise, Collect the precipitate, wash it with deionized water, and dry it to obtain a ruthenium-graphene oxide composite; graphene oxide is nano-graphene with a sheet size of 3-500nm and edges containing functional groups that can form coordination bonds with trivalent ruthenium ions; The amount of trivalent ruthenium ions in the ruthenium chloride solu...

Embodiment 2

[0033] A preparation method of graphene-ruthenium oxide nanocomposite material, comprising the following steps:

[0034] (1) Citric acid and histidine are placed in a beaker at a molar ratio of 2:3, and graphene quantum dots are obtained after reacting at 200° C., and the graphene quantum dots are dispersed in deionized water to obtain an aqueous solution of graphene quantum dots;

[0035] (2) disperse graphene oxide in deionized water to obtain an aqueous solution, add the graphene quantum dot aqueous solution prepared in step (1) under stirring, adjust the pH to neutrality and add ruthenium chloride solution dropwise, collect the precipitate, remove Washing with ionic water and drying to obtain ruthenium-graphene oxide composite; graphene oxide is nano-graphene with a sheet size of 3-500nm and edges containing functional groups that can form coordination bonds with trivalent ruthenium ions; ruthenium chloride solution The amount of trivalent ruthenium ions in the compound is...

Embodiment 3

[0039] A preparation method of graphene-ruthenium oxide nanocomposite material, comprising the following steps:

[0040] (1) Citric acid and histidine are placed in a beaker at a molar ratio of 2:1, and graphene quantum dots are obtained after reacting at 160° C., and the graphene quantum dots are dispersed in deionized water to obtain an aqueous solution of graphene quantum dots;

[0041] (2) disperse graphene oxide in deionized water to obtain an aqueous solution, add the graphene quantum dot aqueous solution prepared in step (1) under stirring, adjust the pH to neutrality and add ruthenium chloride solution dropwise, collect the precipitate, remove Washing with ionic water and drying to obtain ruthenium-graphene oxide composite; graphene oxide is nano-graphene with a sheet size of 3-500nm and edges containing functional groups that can form coordination bonds with trivalent ruthenium ions; ruthenium chloride solution The amount of trivalent ruthenium ions in the compound is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com