Porous platinum preparation method and application of porous platinum

A metal platinum and platinum alloy technology, applied in the field of platinum catalyst preparation, can solve the problems of restricting the application of porous platinum catalyst, complex preparation process, dangerous chemical reagents, etc., achieve the effect of controllable size, uniform pore size distribution, and avoid waste pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

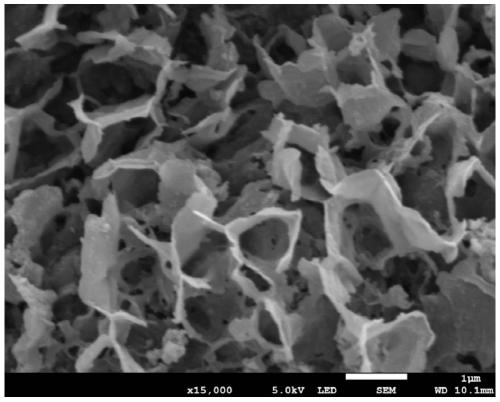

Image

Examples

Embodiment 1

[0031] A preparation method of porous platinum, comprising the following steps: take 1g of platinum powder and 1g of copper powder, heat under vacuum at 1700°C for 2h, then heat at 2800°C for 0.5h, and cool to room temperature to obtain porous platinum.

Embodiment 2

[0033] A preparation method of porous platinum, comprising the following steps: take 1g of platinum powder and 5g of nickel powder, heat at 1900°C for 4h under vacuum, then heat at 2700°C for 2h, and cool to room temperature to obtain porous platinum.

Embodiment 3

[0035] A method for preparing porous platinum, comprising the following steps: take 1g of platinum powder and 0.5g of aluminum powder, heat under vacuum conditions at 1600°C for 10h, then heat at 2500°C for 0.6h, and cool to room temperature to obtain porous platinum .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com