Flexible substrate CdTe thin-film solar cell and preparing method thereof

A technology for solar cells and flexible substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large material consumption, complicated preparation process, and high production cost, and achieve good film quality, simple process, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

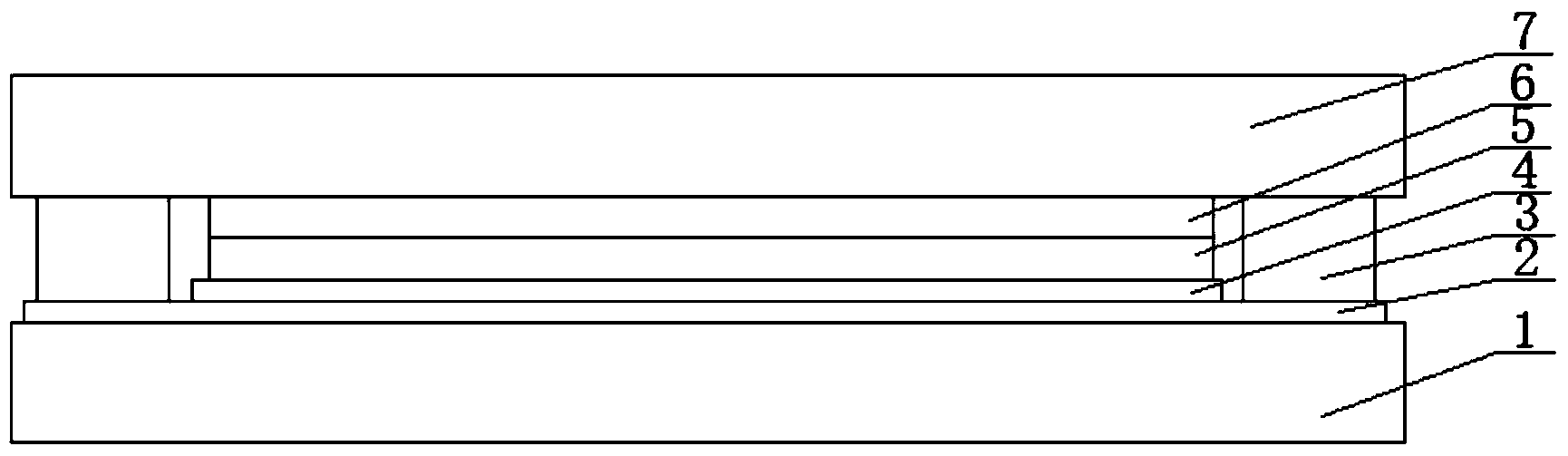

[0034] This embodiment discloses a flexible substrate CdTe thin film solar cell, which is composed of seven parts, the seven parts are respectively flexible substrate thin film material layer 1, transparent conductive thin film layer 2, negative electrode 3, and CdS thin film window Layer 4, CdTe thin film absorber layer 5, back electrode metal contact layer 6 and flexible thin film material encapsulation layer 7.

[0035] Such as figure 1 As shown, in this embodiment, a transparent flexible substrate film material layer 1 is specifically set for the bottom layer; Zn is deposited at a low temperature on the flexible substrate film material layer 1 x Cd 1-x The transparent conductive thin film layer 2 that 0 forms; Screen printing silver paste on the partial position of transparent conductive thin film layer 2, the negative electrode 3 that is used to collect electric current that forms; 4), be arranged on transparent conductive thin film layer 2 unprinted silver paste The Cd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com