Plant fiber environmental protection material and its manufacturing method and application

A technology of plant fibers and environmentally friendly materials, applied in applications, other household appliances, household components, etc., can solve problems such as difficulty in uniform dispersion, low interface bonding strength, mechanical properties, water resistance, and durability, and reach a broad market Foreground, enhanced material performance, strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Present embodiment is used for making tableware, and adopted raw material and content thereof are listed in the following table:

[0047] components

parts by mass

100

Titanium dioxide

20

hydrogenated rosin

20

Hydroxypropylmethylcellulose

20

Tetrabutyl titanate

20

calcium lignosulfonate

10

2

2

1

1

[0048] Dicyandiamide

1

1

Zinc borate

1

1

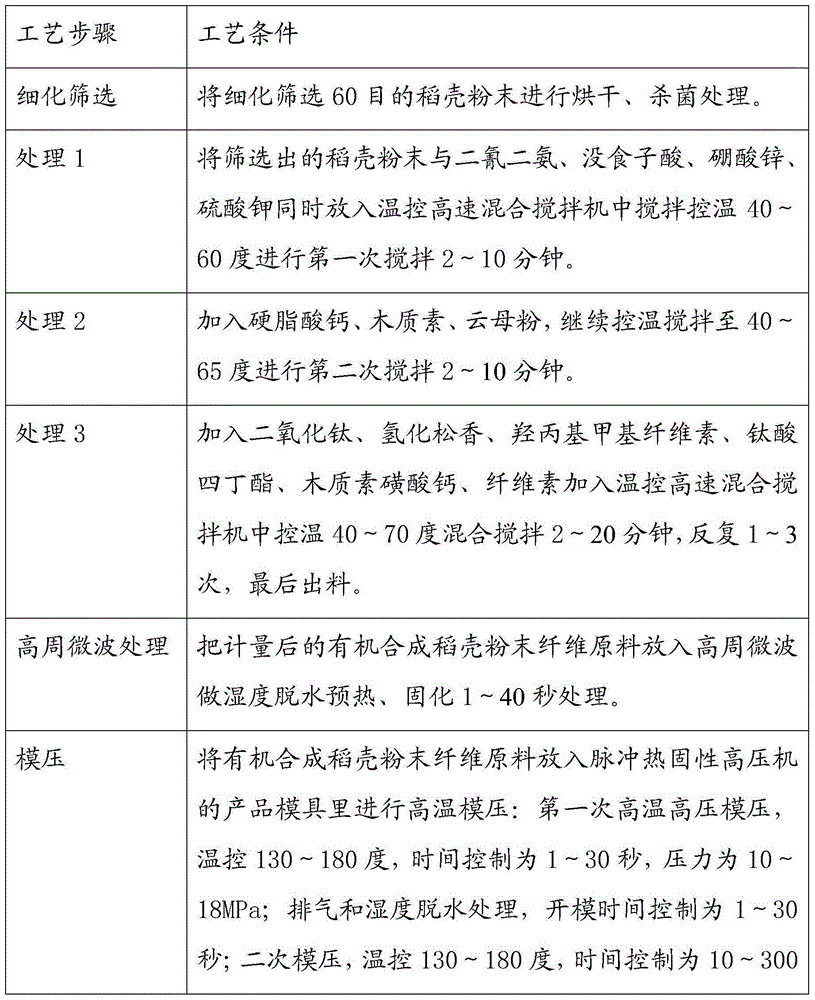

[0049] The process conditions of each step are listed in the following table in the present embodiment:

[0050]

[0051]

[0052] The rice husk fiber composite tableware manufactured by the present embodiment complies with GB9690-2009 (hygienic standard for melamine-formaldehyde molded products for food containers and packaging materials), GB18006.1-20...

Embodiment 2

[0054] Present embodiment is used for making rice husk fiber composite anion health-care tableware, and its raw material formula is listed in the following table:

[0055] components

parts by mass

rice husk powder

100

Titanium dioxide

20

hydrogenated rosin

20

Hydroxypropylmethylcellulose

20

Tetrabutyl titanate

20

[0056] calcium lignosulfonate

10

1

Dicyandiamide

1

1

Zinc borate

1

1

medical stone and tourmaline

5

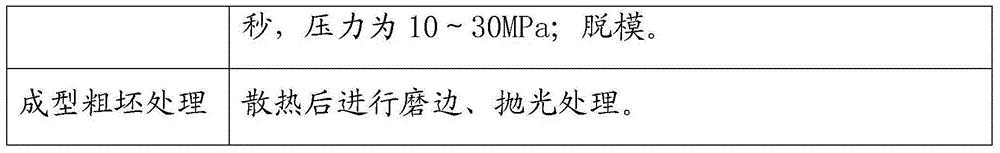

[0057] The process conditions of each step are listed in the following table in the present embodiment:

[0058]

[0059]

[0060] The rice husk fiber composite negative ion health-care tableware manufactured in this embodiment complies with GB9690-2009 and GB18006.1-2009, and is tested by the SGS-CSTC chemical laboratory and meets the FDA's requiremen...

Embodiment 3

[0062] This embodiment is used to make rice husk fiber composite nano-silver tableware, and its raw material formula is listed in the following table:

[0063] components

parts by mass

rice husk powder

100

Titanium dioxide

10

hydrogenated rosin

10

Hydroxypropylmethylcellulose

40

Tetrabutyl titanate

10

calcium lignosulfonate

10

5

5

Mica powder

5

Nano silver (liquid)

5

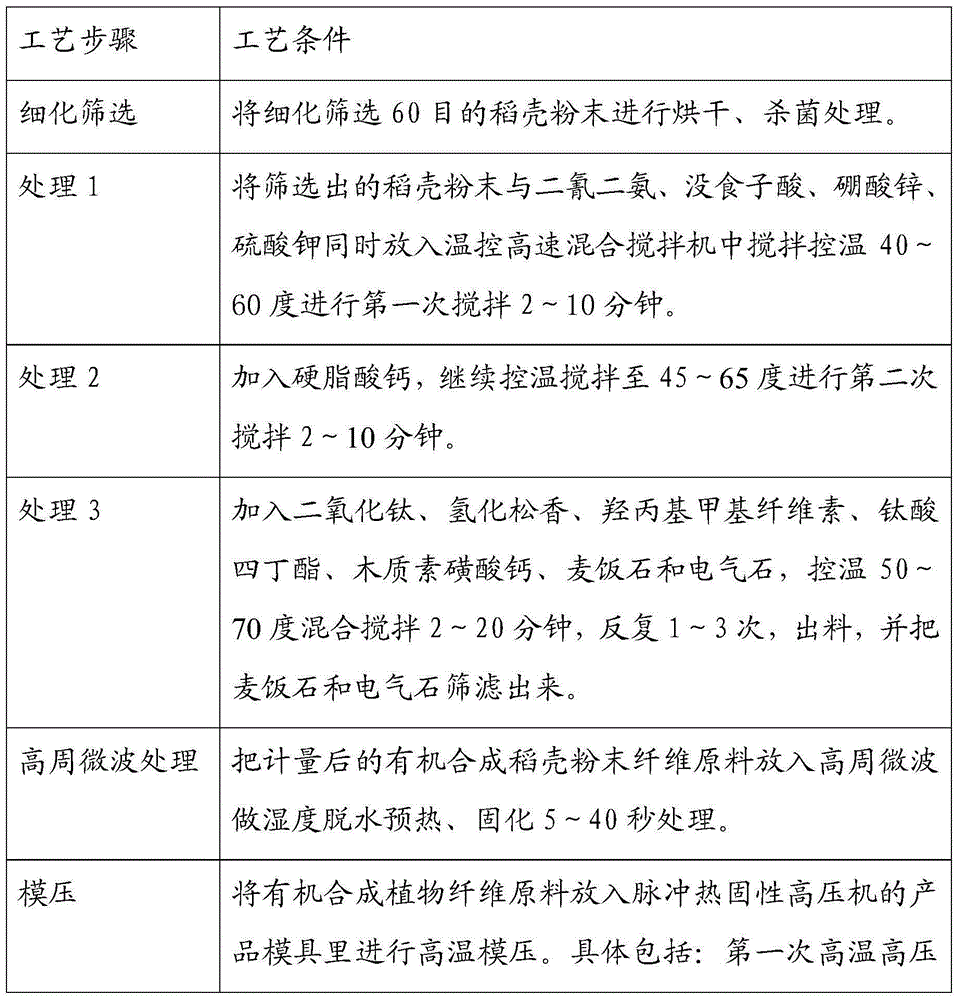

[0064] The process conditions of each step are listed in the following table in the present embodiment:

[0065]

[0066]

[0067] The tableware manufactured in this example complies with GB9690-2009 and GB18006.1-2009, and is tested by the SGS-CSTC chemical laboratory, and meets FDA’s requirements for the content of chloroform extractable substances in melamine-formaldehyde products, and is tested by the SGS Taipei Food Laboratory , in line with JISZ28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com