Porous metal foil as well as preparation method and application thereof

A porous metal and metal foil technology, applied in the field of porous metal foil and its preparation, can solve the problems of complex preparation process, environmental hazards, high cost, etc., and achieve the effect of simple and easy method, low equipment requirements, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of porous copper foil: put the copper foil into a solution composed of 20mL ethylene glycol and 1.36g zinc chloride, -2 Electroplating at a current density of 20 minutes to obtain a layer of metallic zinc, then heating at 200°C for 3h under vacuum conditions, and finally heating at 600°C for 2h, the porous copper foil can be prepared.

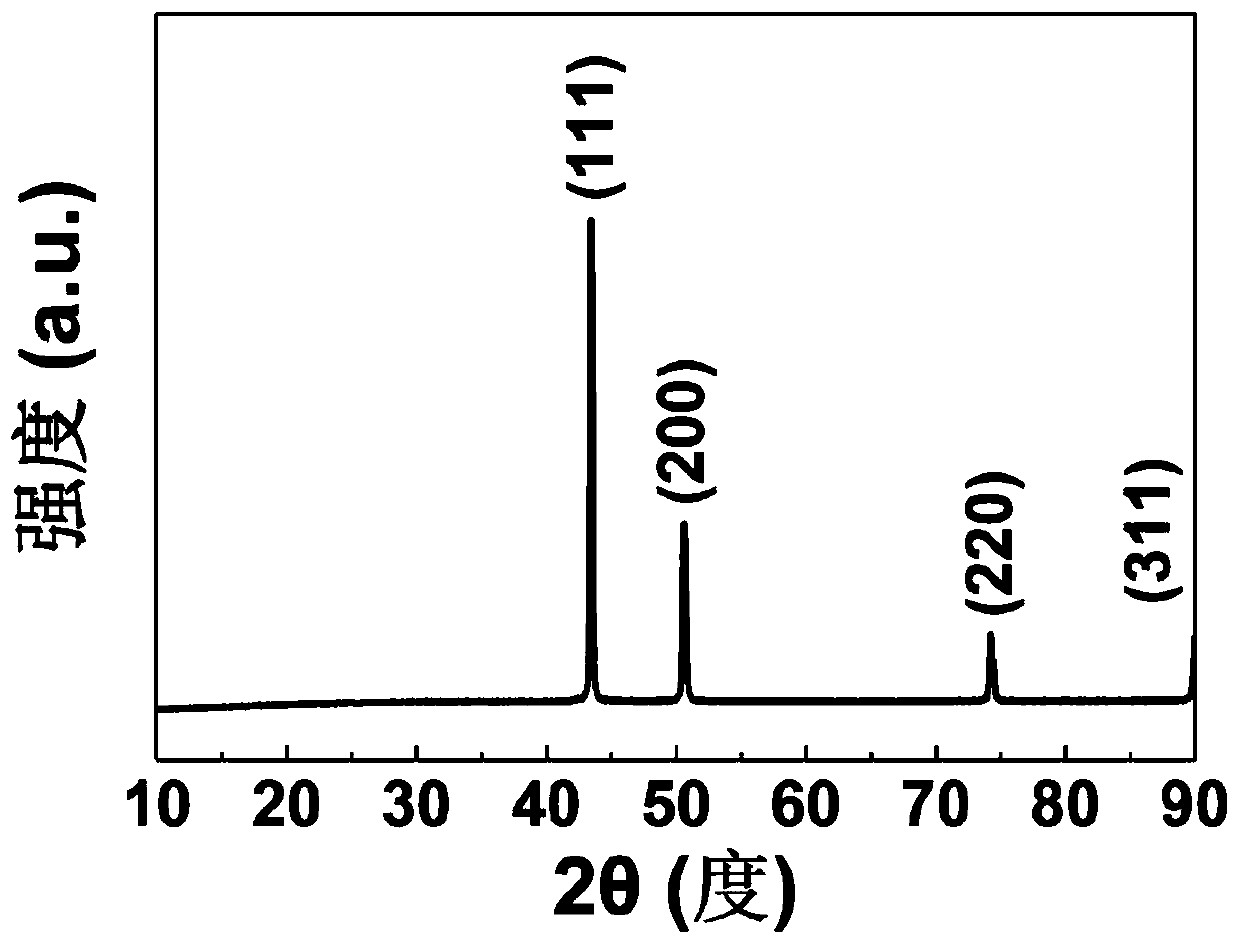

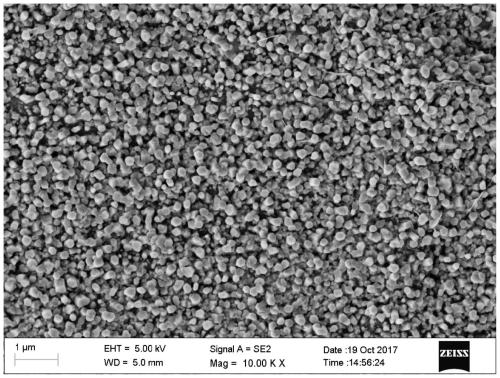

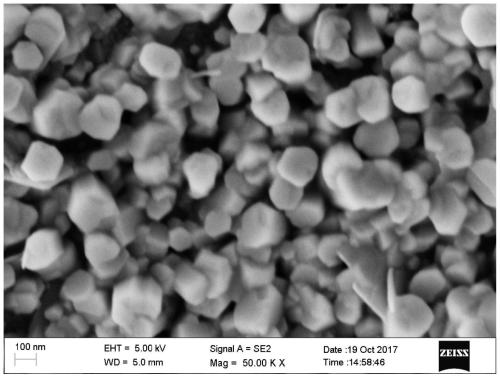

[0034] figure 1 is the XRD of porous copper foil. figure 2 and image 3 It is the SEM of porous copper foil. It shows that high-purity, porous copper foil is synthesized.

Embodiment 2

[0036] A kind of preparation method of porous aluminum foil: copper foil is put into the solution that 50mL propylene carbonate and 2.11g magnesium sulfate are formed, with 5mA cm -2 Electroplating at a current density of 10 minutes to obtain a layer of metal magnesium, then heating at 300°C for 2h under vacuum conditions, and finally heating at 800°C for 1h, the porous aluminum foil can be prepared.

Embodiment 3

[0038] A preparation method of porous titanium foil: put the copper foil into a solution composed of 100mL isopropanol and 4.21g zinc citrate, with 0.8mA cm -2 Electroplating at a current density of 120 minutes to obtain a layer of metal zinc, then heating at 100°C for 4h under vacuum conditions, and finally heating at 500°C for 5h, the porous titanium foil can be prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com