Preparation method for novel welding-resistant ablation-resistant long-service-life copper-chromium contact material

A contact material and anti-welding technology, applied in the direction of contacts, electrical components, circuits, etc., can solve the problem that the degree of densification cannot be guaranteed, and achieve equivalent conductivity, high anti-welding resistance and ablation resistance Sexuality, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

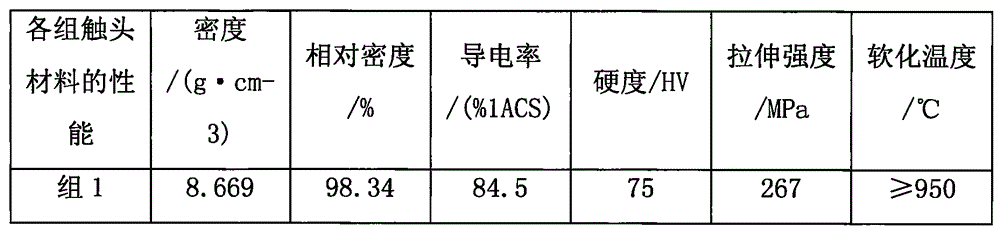

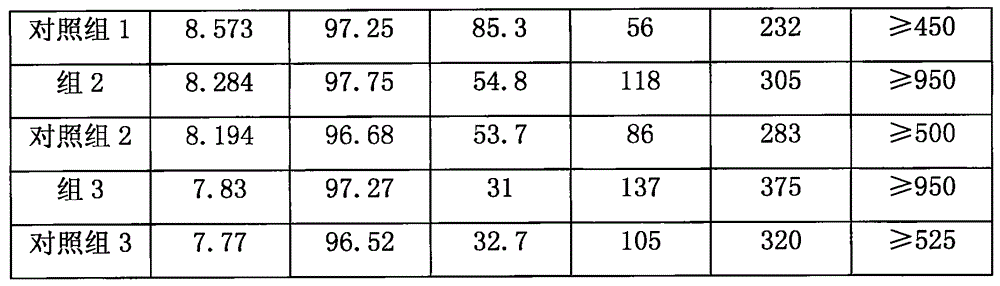

Embodiment 1

[0024] A Novel Anti-welding and Anti-ablation Cu-nano-Al 2 o 3 -The preparation method of Cr contact material, the steps are as follows:

[0025] (1) Ingredients: According to the alloy composition, Al 2 o 3 Content is 1.2wt% dispersion strengthened Cu powder and Cr powder according to the ratio of Cr weight content is 5wt% batching; Wherein, described Cu-Al 2 o 3 The powder is prepared by internal oxidation method, the powder particle size is -80 mesh, the Cu-Al 2 o 3 The preparation method of the powder is: first conduct induction melting of Cu, gradually raise the temperature and control the melting temperature at 1150°C until the copper is completely melted, then add the required Cu-Al alloy powder according to the composition requirements after 3-5 minutes, and sieve, with H 2 Partially oxidized part of the alloy is re-reduced, and the Cu-Al alloy powder and Cu 2 O powder is mixed with powder, placed in a closed container, and internally oxidized at 900°C for 2.5h...

Embodiment 2

[0031] A Novel Anti-welding and Anti-ablation Cu-nano-Al 2 o 3 -The preparation method of Cr contact material, the steps are as follows:

[0032] (1) Ingredients: According to the alloy composition, Al 2 o 3The content is 1.2wt% dispersion strengthened Cu powder and Cr powder according to the ratio of Cr weight content is 25wt%; Wherein, the Cu-Al 2 o 3 The powder is prepared by internal oxidation method, the powder particle size is -80 mesh, the Cu-Al 2 o 3 The preparation method of the powder is as follows: first conduct induction melting of Cu, gradually raise the temperature and control the melting temperature between 1180°C until the copper is completely melted, and then add the required Cu-Al alloy according to the composition requirements after 3-5 minutes, until all Melt, then gas atomize powder, obtain Cu-Al alloy powder, sieve, use H 2 Partially oxidized part of the alloy is re-reduced, and the Cu-Al alloy powder and Cu 2 O powder is mixed with powder, placed...

Embodiment 3

[0038] A Novel Anti-welding and Anti-ablation Cu-nano-Al 2 o 3 -The preparation method of Cr contact material, the steps are as follows:

[0039] Ingredients: According to the alloy composition, Al 2 o 3 The content is 1.2wt% dispersion strengthened Cu powder and Cr powder according to the ratio of Cr weight content is 50wt%; Wherein, the Cu-Al 2 o 3 The powder is prepared by internal oxidation method, the powder particle size is -80 mesh, the Cu-Al 2 o 3 The preparation method of the powder is: first conduct induction melting of Cu, gradually raise the temperature and control the melting temperature between 1200°C until the copper is completely melted, and then add the required Cu-Al alloy according to the composition requirements after 3-5 minutes, until all Melt, then gas atomize powder, obtain Cu-Al alloy powder, sieve, use H 2 Partially oxidized part of the alloy is re-reduced, and the Cu-Al alloy powder and Cu 2 O powder is mixed with powder, placed in a closed c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com