Yarn twist contraction performance test method and device

A technology of testing device and testing method, which is applied in the direction of measuring device, applying stable tension/pressure to test material strength, strength characteristics, etc., can solve the problems of no yarn twist shrinkage testing instrument and method, etc., and achieve simple and convenient operation, The effect of accurate test effect and simple instrument structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

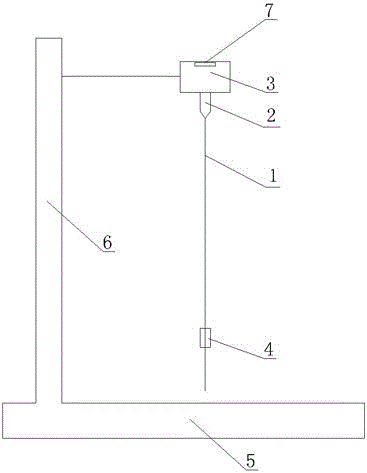

[0031] Such as figure 1 As shown, a yarn twist shrinkage performance testing device of the present invention includes a base 5 and a support frame 6, the base 5 and the support frame 6 can adopt an integrated structure or a split structure, and a stepping motor is installed on the support frame 6 3. A pneumatic clamp 2 is connected to the lower end of the stepping motor 3, one end of the yarn 1 is connected to the pneumatic clamp 2, and the other end of the yarn 1 is connected to a tension controller 4.

[0032] The control device 7 is connected with the stepping motor 3, and the direction of rotation, the speed of rotation and the number of rotations of the stepping motor 3 are controlled and regulated by the control device 7. By controlling the direction of rotation, the speed of rotation and the number of rotations of the stepping motor 3, Realize the coordinated rotation of the pneumatic clamp 2; in this embodiment, the control device 7 preferably selects a single-chip mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com