Coverage type karst collapse simulation test device and operation method thereof

A karst collapse and simulation test technology, applied in the field of karst ground subsidence research, can solve the problems of many influencing factors, affecting the reliability of simulation, and the difficulty in analyzing the interaction mode and influence law of multi-structure collapse, and achieve convenient test conditions and simulation The effect of complex working conditions and rich test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

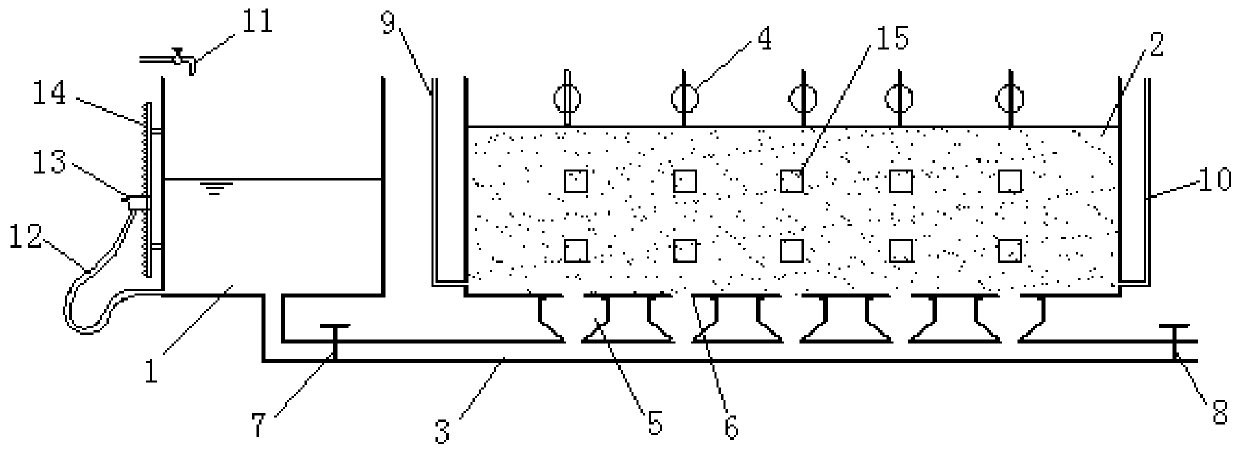

[0045] Attached below Figure 1-Figure 7 The present invention is described in detail, specifically, the structure is as follows:

[0046] This embodiment provides a covered karst collapse simulation test device, including a water level control box 1, a collapse simulation box 2, an overflow device, a water passage 3, and a karst structure opening 5, and the overflow device is installed on the side of the water level control box 1 There are multiple karst structure openings 5, and they are installed at the bottom of the collapse simulation box 2;

[0047] The water inlet valve 7 is installed near one end of the water level control box 1 bottom of the water passing pipeline 3, and the drain valve 8 is installed at the other end of the water passing pipeline 3, and the water supply for the collapse simulation box 2 is provided by opening the water inlet valve 7 and closing the drain valve 8. At the same time, the water passing pipe 3 can provide a migration channel for the coll...

Embodiment 2

[0056] The karst structure opening 5 at the bottom of the collapse simulation box 2 is closed by controlling the valve 6, and then soil is filled into the collapse simulation box 2 according to the design parameters. When filling the soil, it needs to be laid layer by layer according to a certain density until the design thickness is reached. At the same time, a certain number of stress-strain sensors 15 are buried according to the test requirements to monitor the stress and strain data at different positions during the soil layer subsidence process.

[0057] During the soil filling process, use a sponge to block the piezometric tubes 9 and 10 on both sides of the collapse simulation box 2 where they are in contact with the soil, so as to prevent the soil from clogging the piezometric tubes 9 and 10 and thus affecting the water level measurement Accuracy, at the same time, paste the vertical scale on the pipe wall for easy reading.

[0058] After the filling is completed, a pl...

Embodiment 3

[0063] The karst structure opening 5 at the bottom of the collapse simulation box 2 is closed by controlling the valve 6, and soil is filled into the collapse simulation box 2. Afterwards, according to the test design conditions, two rock structure control valves 6 with different spacings are opened. For example, 1. fully open the second and third karst structure control valves 6 at the bottom of the collapse simulation box 2 as the first research condition; 2. set the second and fourth control valves 6 at the bottom of the collapse simulation box 2 Fully open as the second working condition; 3. Fully open the first and fifth control valves 6 at the bottom of the collapse simulation box 2 as the third working condition.

[0064] At the same time, the height of the water level in the water level control box 1 and the thickness of the soil layer in the collapse simulation box 2 were set as fixed values, and other test operation steps were the same as in the second embodiment. B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com