A low-impact space butt sealing device butt performance test system

A space docking and sealing device technology, applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve the impact of low-impact space docking system on the overall performance and function realization, sealing structure tear failure, docking Problems such as the inability of the aircraft to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

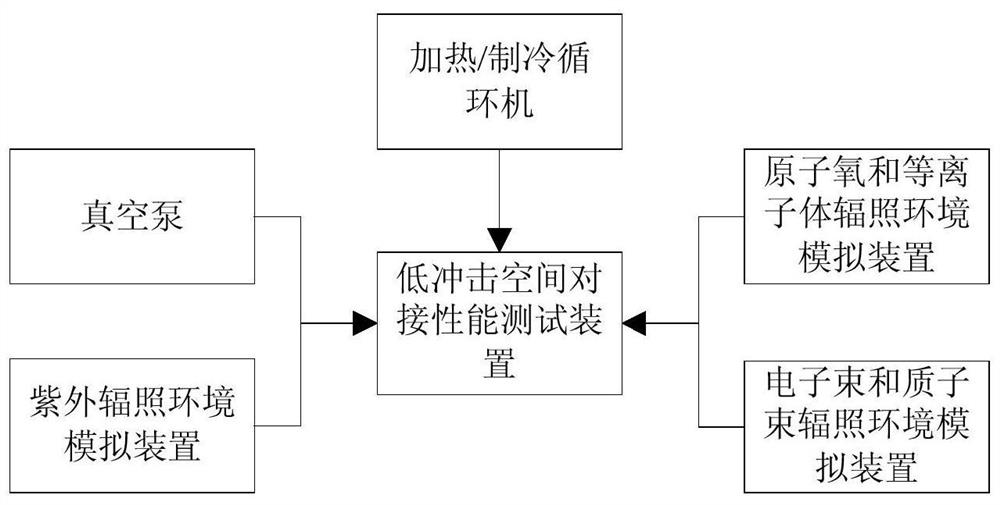

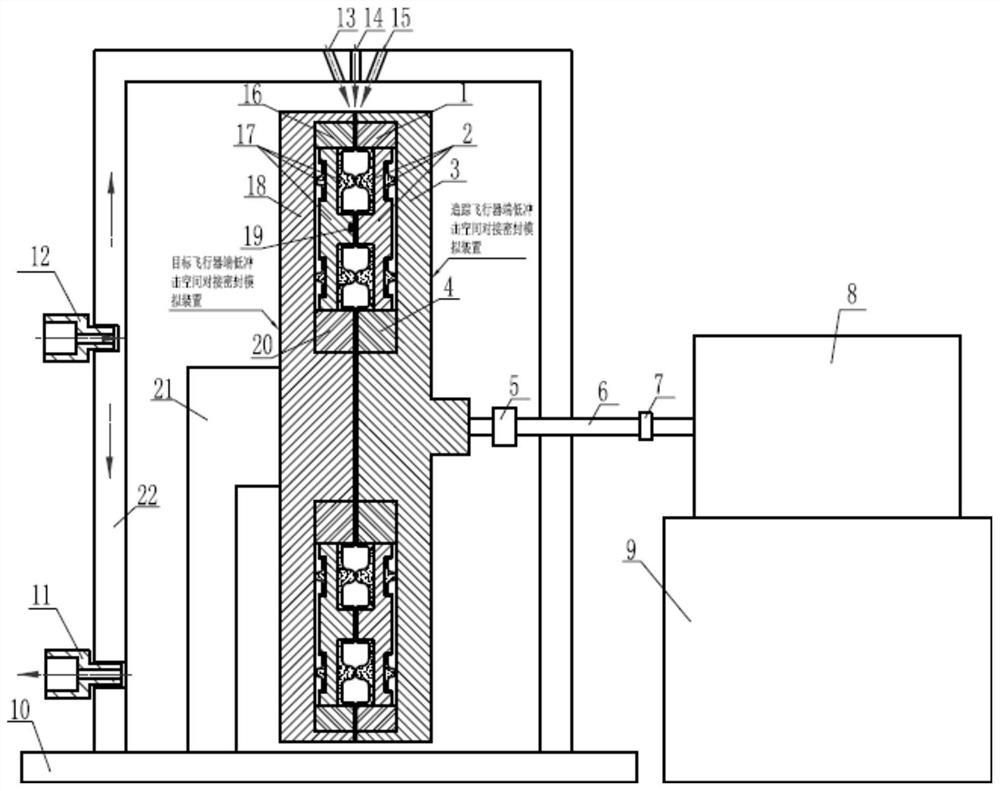

[0034] Aiming at the structural characteristics, working environment and docking and separation requirements of the new low-impact space docking and sealing device of spacecraft, the present invention proposes a low-impact space docking and sealing device docking performance test system, which can simulate the vacuum and temperature in the process of spacecraft space docking and irradiation environment, carry out docking performance tests of sealed test pieces of different specifications under various working conditions, and systematically and comprehensively verify the docking performance of low-impact space docking sealing devices, including the extrusion force during docking and maintenance, and the separation process. The adhesion force and the friction and wear during the butt separation process provide experimental support for the material selection, structural design, component assembly and engineering application of the low-impact space butt joint sealing device.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com