Method and apparatus for drying nanometer pattern by using microwave

A technology of microwave drying and nano-patterns, which is applied to microstructure devices, heating devices, drying, etc., can solve the problems of nano-pattern collapse, lodging or destruction, and achieve the effects of reducing mass use, protecting the environment and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

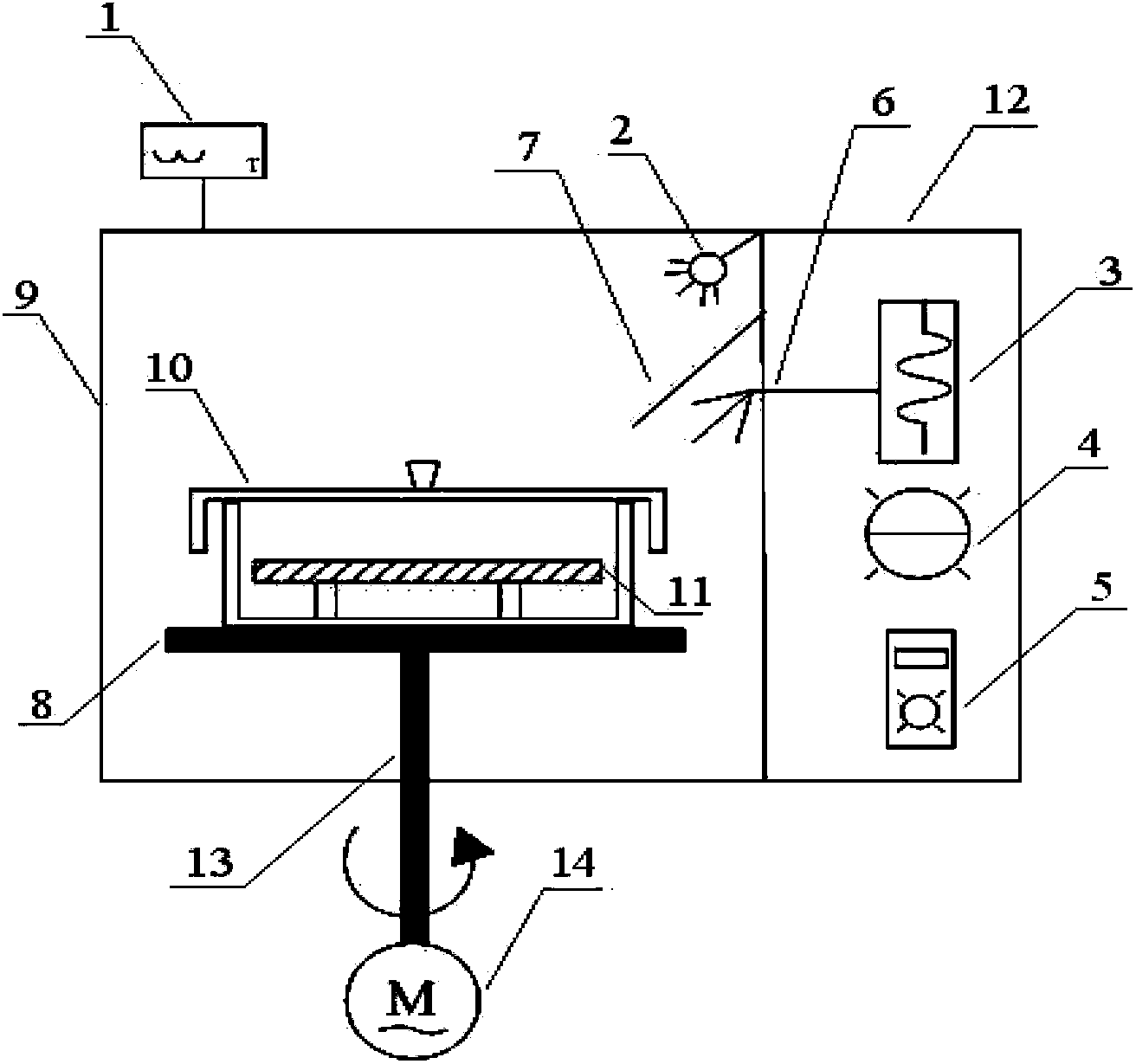

[0023] Such as figure 1 It can be seen that the device used to realize the drying process in the present invention includes: fluorescent lamp 2, microwave generator 3, magnetron 6, quartz cleaning box 10, turntable 8, rotating rod 13, motor 14 and power supply. Wherein, the fluorescent lamp 2 is connected with a power source and fixed inside the microwave resonant cavity 9 . The microwave generator 3 is connected with the power supply and fixed in the control panel box 12 . The output of the microwave generator 3 is connected with the magnetron 6, and the other end of the magnetron 6 is connected with the power supply. The quartz cleaning box 10 can be fixed on the turntable 8 . The motor 14 is connected with the turntable 8 through the rotating rod 13 . Among them, the fluorescent lamp 2 is preferably a yellow fluorescent lamp. In this embodiment, the microwave generator 3 is used to generate high-frequency microwaves. In this embodiment, the introduction of motors, rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com