Method for repairing copper base-metal organic framework porous material

A metal-organic framework and porous material technology, which is applied in the field of repairing copper-based-metal-organic framework porous materials, can solve problems such as consumption of large ethanol solvent, etc., and achieve the effects of favorable adsorption, high porosity and large BET specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

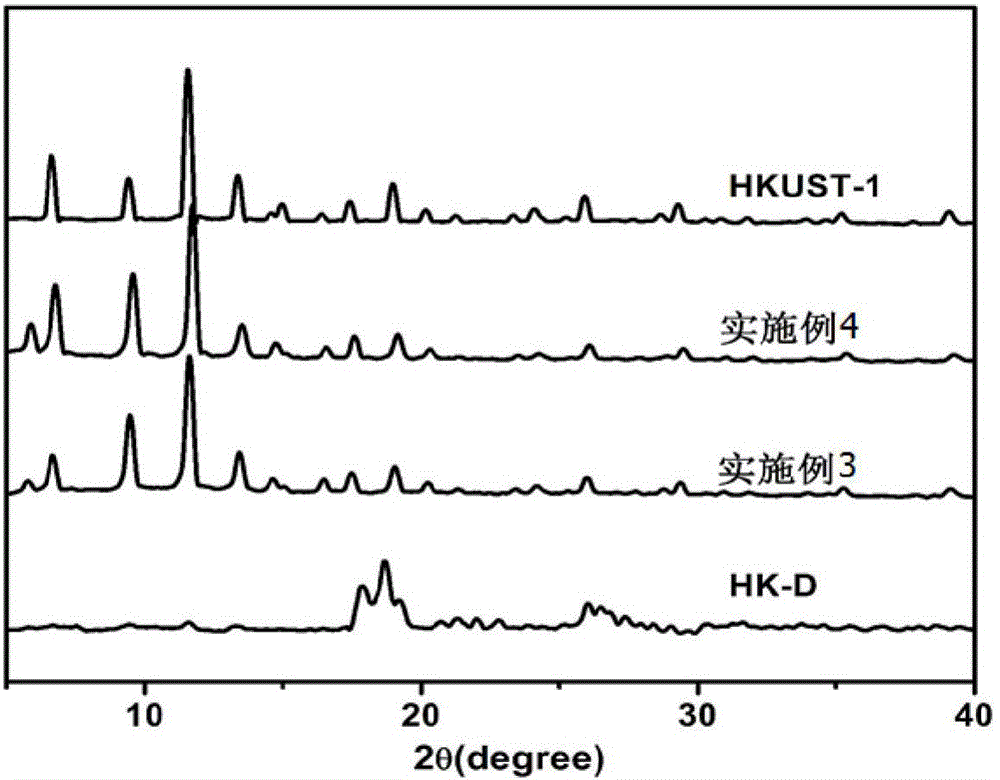

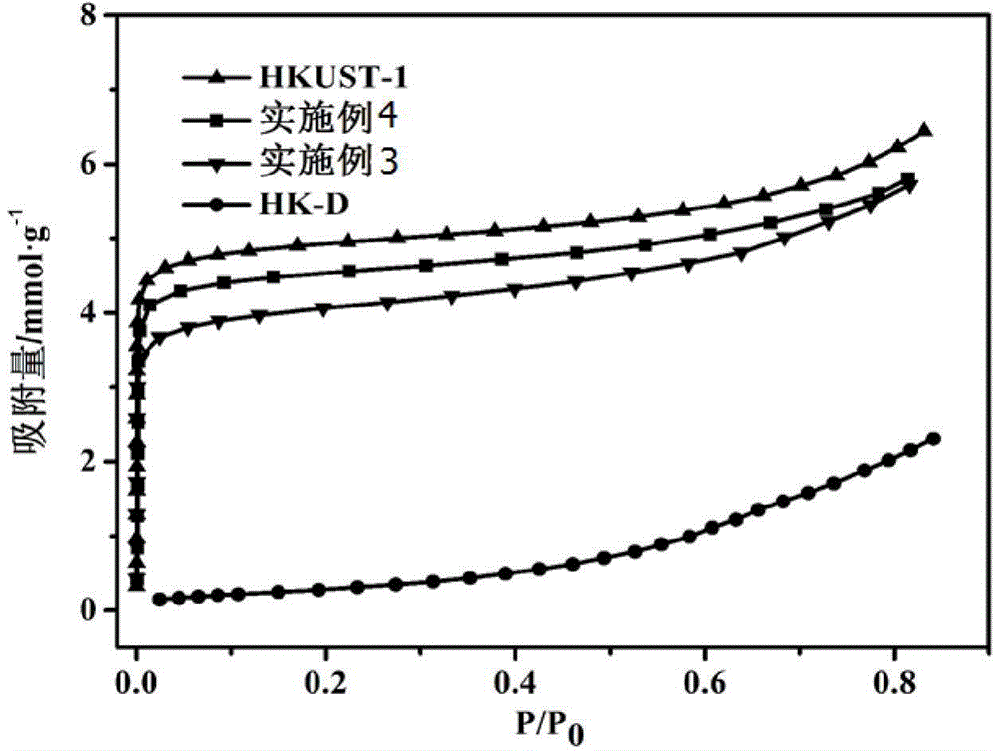

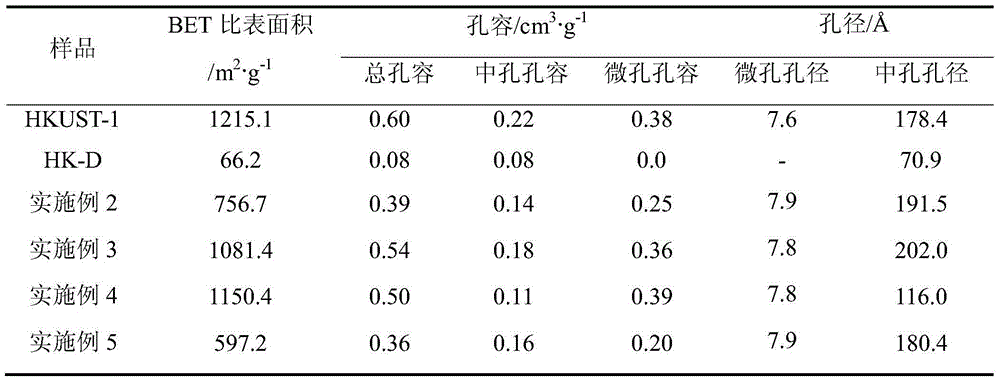

[0029] The method for repairing copper-based-metal organic framework porous materials in the present invention is effective for all copper-based-metal organic framework porous materials whose skeleton structure is destroyed and loses their original adsorption performance. In order to facilitate comparison and description of the effect of the method for repairing copper-based metal-organic framework porous materials described in the present invention, Example 1 provides a copper-based-metal-organic framework porous material prepared according to a conventional method and a copper-based metal-organic framework with a collapsed structure. The organic framework porous material, the specific preparation method is as follows:

[0030] (1) Preparation of Cu-based-MOF porous material: 2.404g Cu(CH 3 COO) 2 ·H 2 O and 1.608g of 1,3,5-benzenetricarboxylic acid were put into a stainless steel ball mill jar, added stainless steel ball mill beads, put into a QM-3C high-speed vibration ba...

Embodiment 2

[0033] A method for repairing copper-based-metal-organic-framework porous materials, comprising the steps of:

[0034] (1) Weigh 0.25 g of the structurally collapsed copper-based metal-organic framework porous material HK-D of Example 1 and place it in a stainless steel ball mill tank, add methanol dropwise at a ratio of 1.2 mL / g, add stainless steel ball mill beads, and put Put it into the QM-3C high-speed vibrating ball mill, then set the rotating speed of the ball mill to 1200r / min (36.60Hz), and ball mill for 10min to obtain a blue solid powder;

[0035] (2) The blue solid powder was vacuum-dried at 140° C. for 5 h to obtain a repaired copper-based metal-organic framework porous material.

Embodiment 3

[0037] A method for repairing copper-based-metal-organic-framework porous materials, comprising the steps of:

[0038] (1) Weigh 0.25 g of the structurally collapsed copper-based metal-organic framework porous material HK-D of Example 1 and place it in a stainless steel ball mill tank, add ethanol dropwise at a ratio of 2 mL / g, add stainless steel ball mill beads, and put In the QM-3C high-speed vibration ball mill, then set the speed of the ball mill to 1100r / min (44.73Hz), and ball mill for 30min to obtain a blue solid powder;

[0039] (2) The blue solid powder was vacuum-dried at 150° C. for 8 hours to obtain a repaired copper-based metal-organic framework porous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com