Additive manufacturing method of electric arc fuse wire with cross structure

A technology of additive manufacturing and electric arc, which is applied in the direction of manufacturing tools, arc welding equipment, welding equipment, etc., can solve problems such as difficult processing and concave intersections, and achieve the effect of controllable angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific example the present invention is described in further detail:

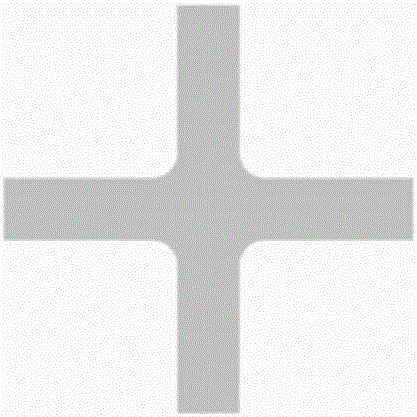

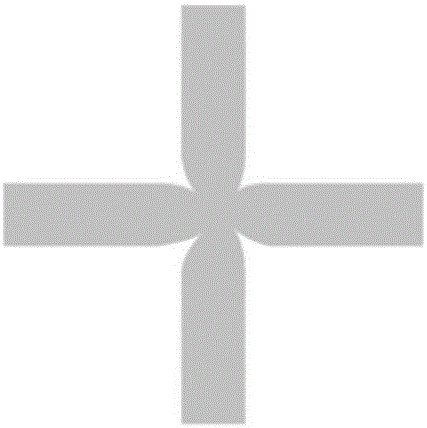

[0032] By adopting the arc fuse additive manufacturing method of the cross structure of the present invention, a multi-layer forming layer grid can be formed on the substrate to achieve a set grid height. The specific implementation steps are as follows:

[0033] (1) Form the first layer of forming layer grid on the substrate, the specific realization process is as follows:

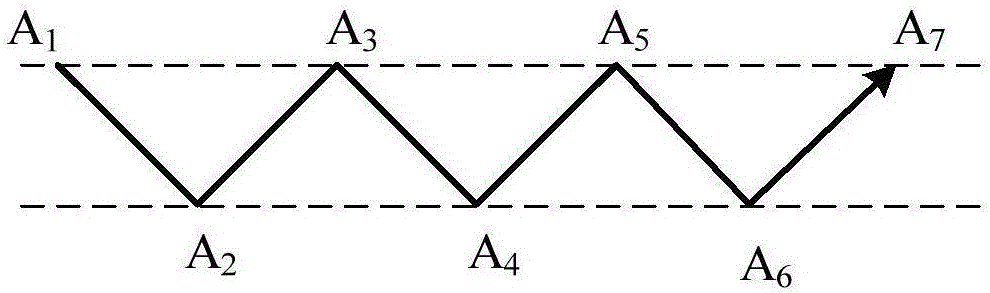

[0034] (1a), set N points on the substrate along the set forming direction, and record them as points A in turn 1 、A 2 ,...,A N , N is a positive integer; then use the arc fuse additive manufacturing process at point A 1 ~A N The first type of single-track shaping layer path is formed between them, and the shaping layer path starts at point A 1 as the arc starting point, with A N is the arc extinguishing point, with A 2 ~AN-1 is the inflection point; where: the inflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com