Method for obtaining structural design parameters

A technology of structural design and parameters, applied in processing data acquisition/processing, improvement of process efficiency, additive manufacturing, etc., can solve problems such as inaccuracy, and achieve the effect of simple operation and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment.

[0033] Use EOS M280 equipment to carry out selective laser melting (SLM) printing on titanium alloy materials, and judge the maximum machinable suspended structure length of its overhanging structure. It is known that the thickness of each layer of titanium alloy processing is set to be 40 μm, and the printing Proceed as follows:

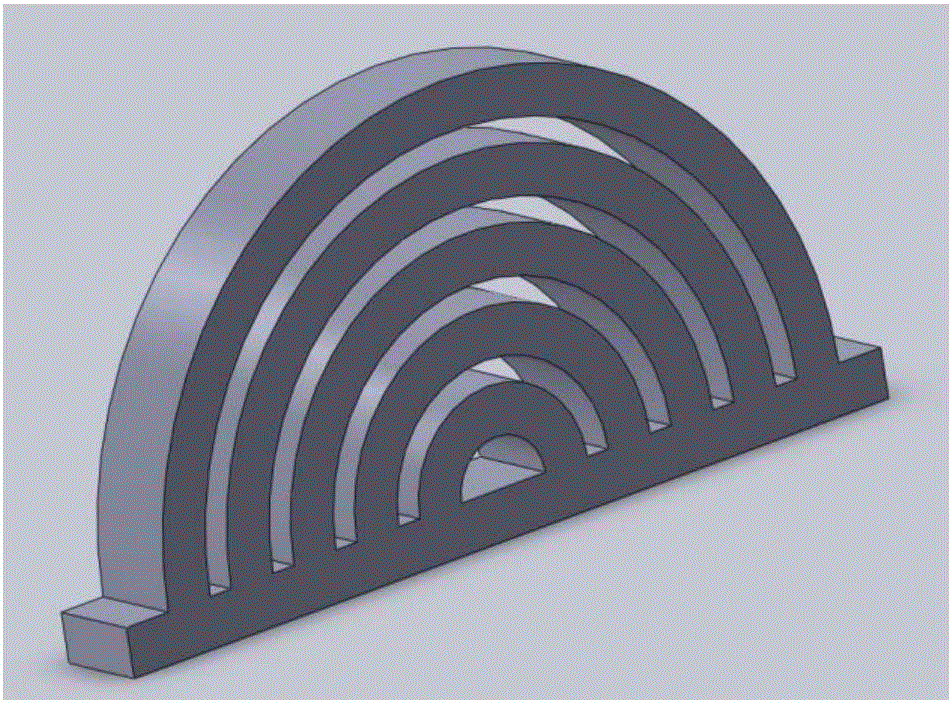

[0034] (1) Design a series of arch structures with different size gradients, and then use titanium alloy powder materials to perform SLM printing on the above series of arch structures (such as figure 2 shown);

[0035] (2) After the printing is completed, test the collapse degree of arch structures of various sizes, and obtain the critical collapse angle (maximum inclination angle) of 85°C;

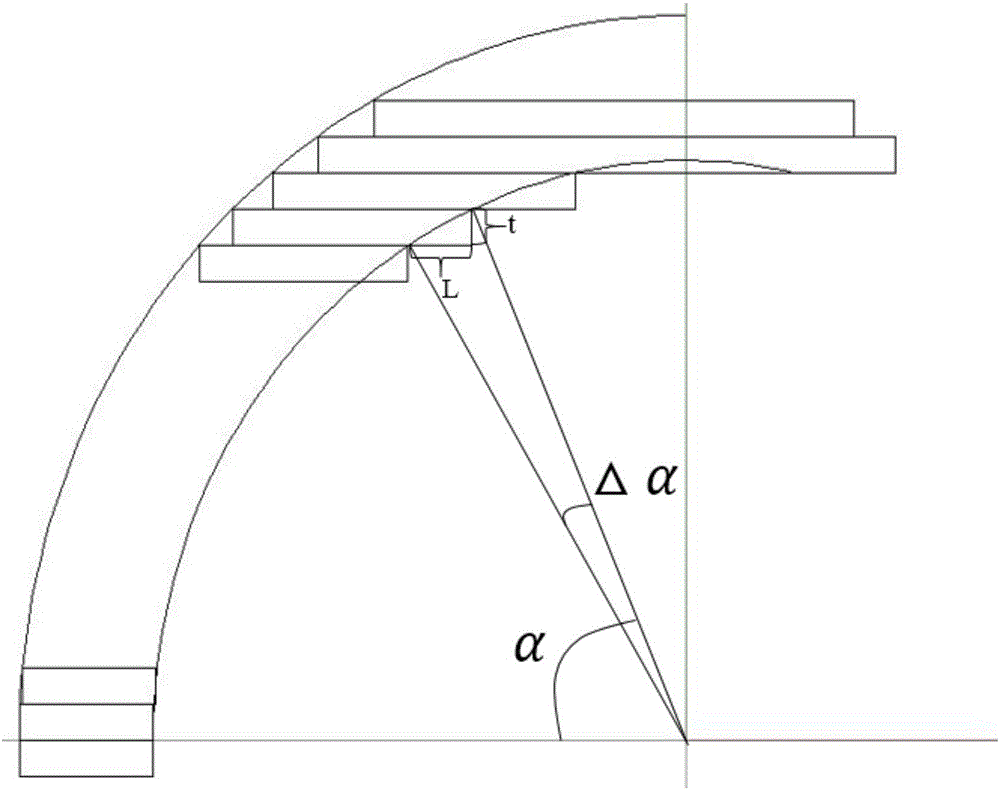

[0036] (3) combine figure 1 The geometric relationship of each parameter in , through calculation, it can be seen that the maximum self-weight bearing length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com