Method for carrying out settlement of underground wall structure by means of high-pressure water guns

A technology of wall structure and high-pressure water gun is applied in the construction of underground building walls and enclosure structures. The high-pressure water gun implements the settlement of underground wall structures, which can solve the problems of high cost, instability and tearing of underground wall structures, etc. problems, to achieve the effect of high work efficiency and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

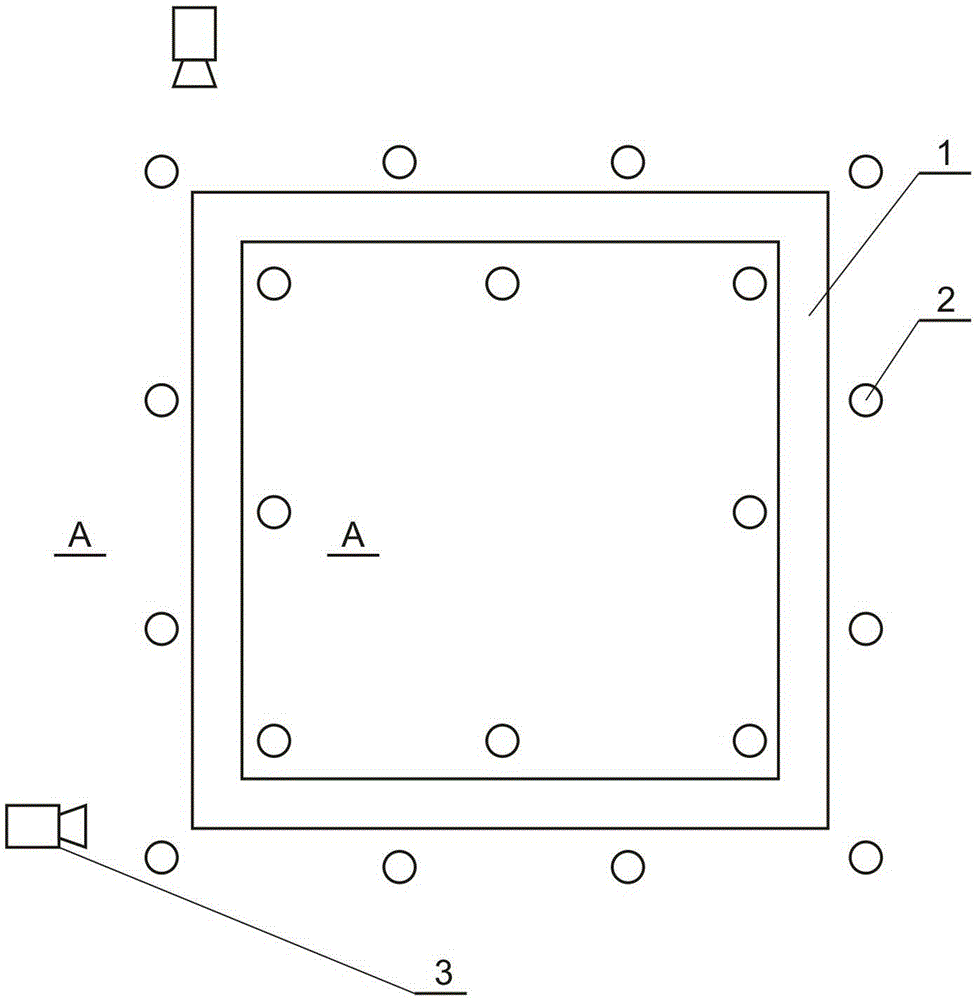

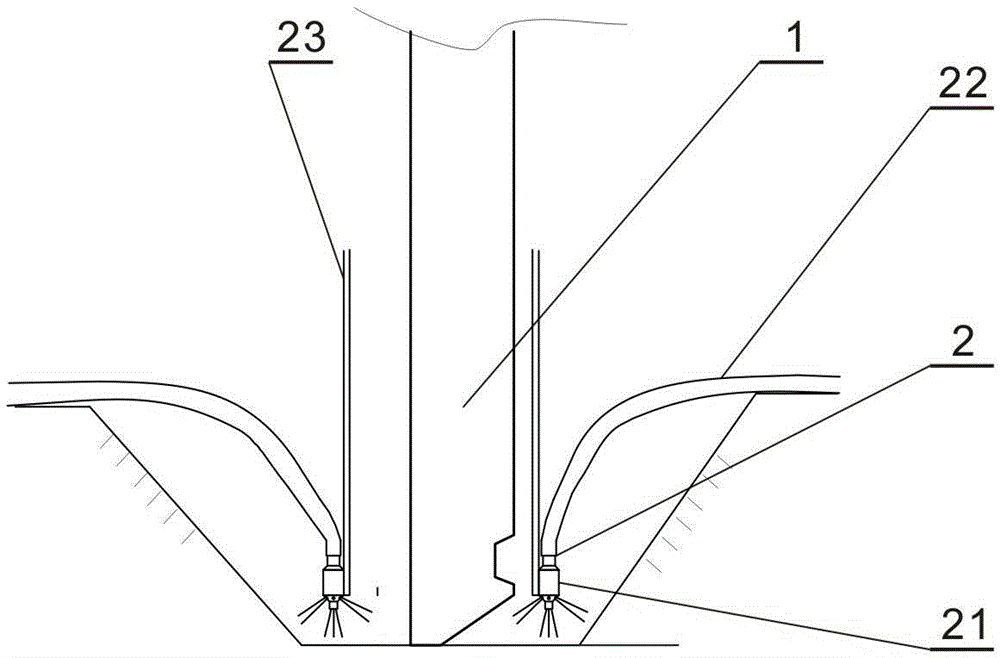

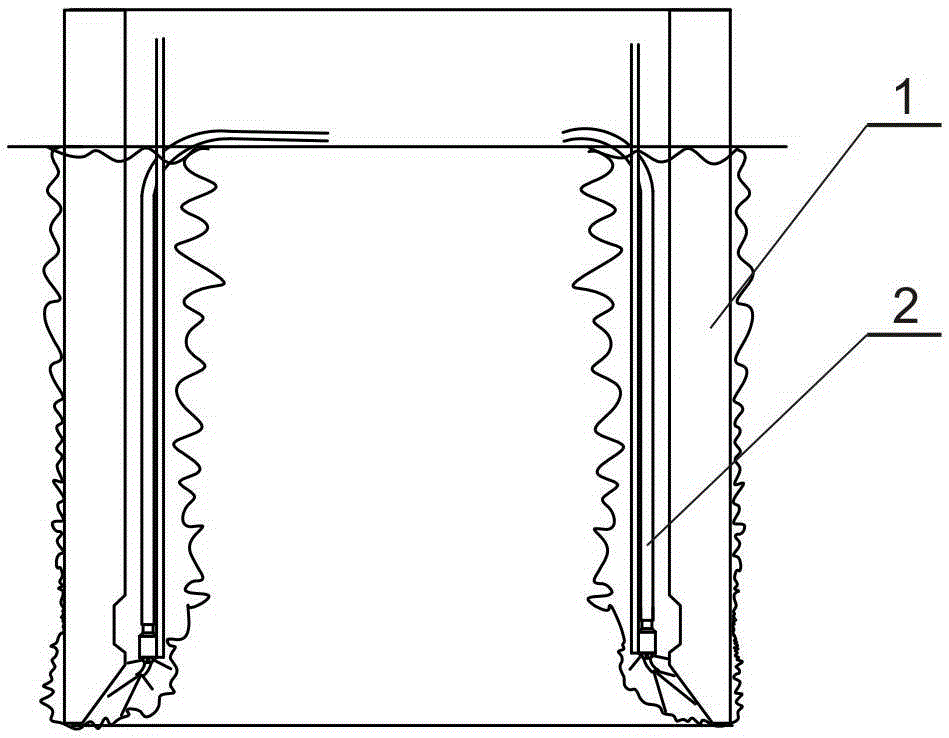

[0028] refer to figure 1 , figure 2 Take the construction of the wall structure of an underground building at a construction site as an example, and the implementation process of the present invention is further described as follows:

[0029] a), Leveling the site and positioning

[0030] Level the site where the subsidence of the underground wall structure is to be implemented and excavate it to the original soil layer, and set the position of the subsidence of the subterranean wall by positioning and laying out lines;

[0031] b), cast-in-place underground wall structure

[0032] According to the design requirements, formwork, cloth reinforcement, and cast-in-place underground wall structure 1 shall be set up on site until the maintenance of underground wall structure 1 is completed, and a cutting edge shall be set at the bottom of the underground wall structure 1, and a protective pad shall be installed under the cutting edge piece;

[0033] c), install the total stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com