Method for butting and synchronously unloading segments of steel truss structure in air

A steel truss and truss technology is applied in the field of high-altitude docking and synchronous unloading of steel truss structures. Effects of Internal Stress and Deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

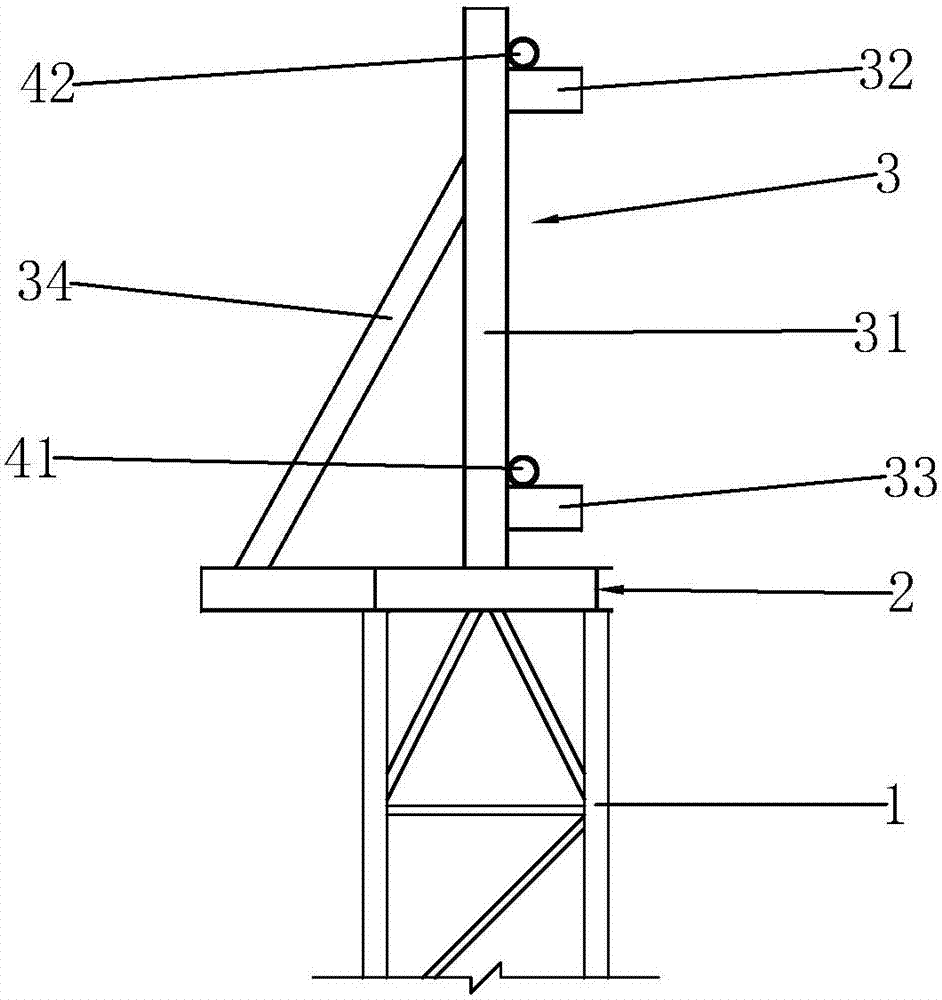

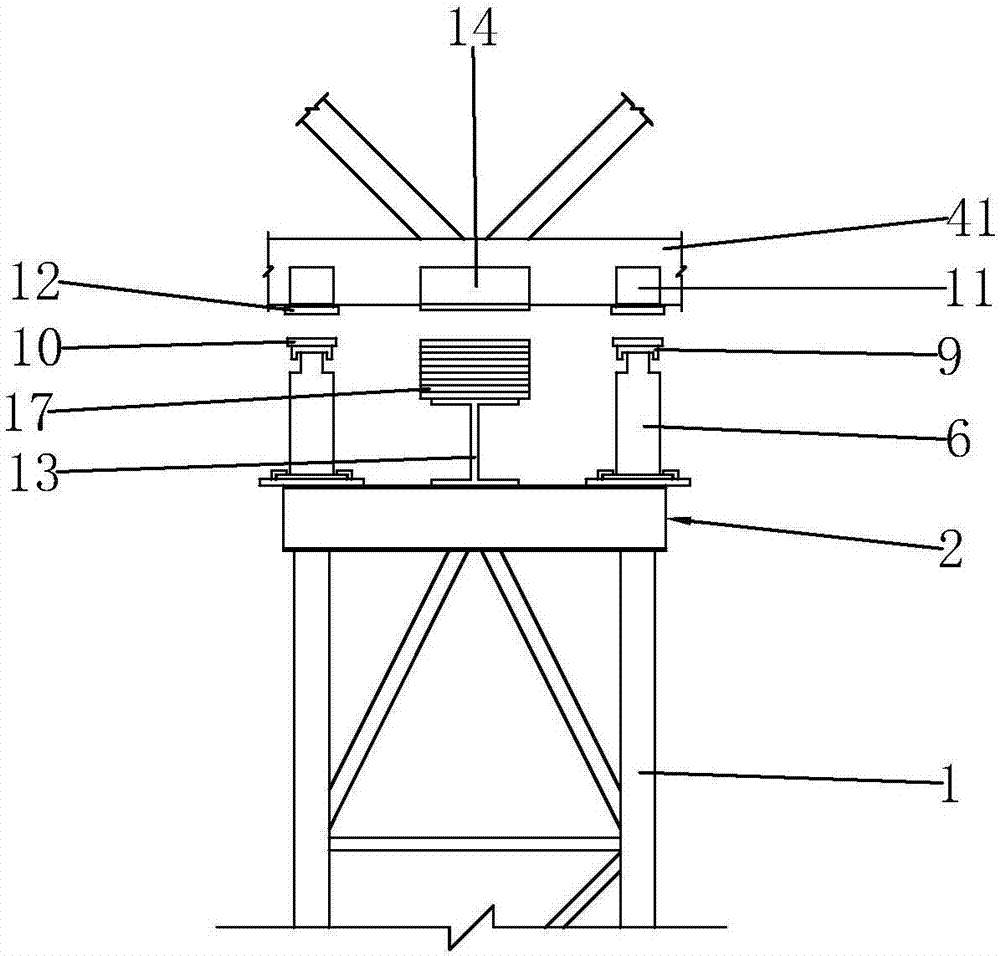

[0044] Such as Figure 1 to Figure 8 As shown, it is a steel truss structure segmented high-altitude docking and synchronous unloading method of the present invention, including the following steps:

[0045] (1) Fabrication and installation of the temporary support frame 1: All components of the temporary support frame 1 are made of square tube profiles, which are connected into a whole by welding. The square tube profiles have good comprehensive mechanical properties, strong corrosion resistance, and good low-temperature toughness. After the production is completed, the temporary support frame 1 is fixed on the original concrete structure through the post-embedded plate, and the temporary support frame 1 can be installed in sections from bottom to top or as a whole according to the specific conditions of the project.

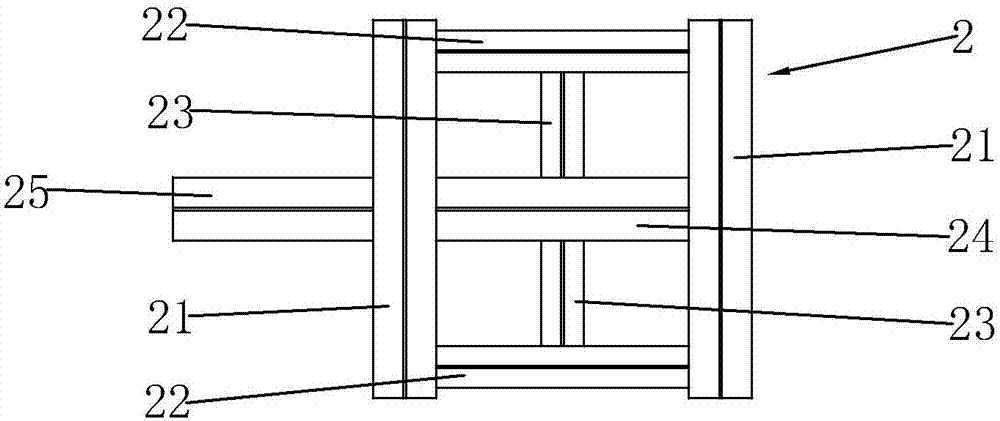

[0046] (2) Manufacture and installation of the operation platform 2: the operation platform 2 includes a first steel beam 21, a second steel beam 22, a third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com