Method for increasing energy density of lithium ion battery and prolonging cycle life of lithium ion battery

A lithium-ion battery and energy density technology, applied in the field of lithium-ion batteries, can solve the problems of reduced battery energy density, reduced capacity, and reduced capacity of lithium-ion batteries, achieving the effect of simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

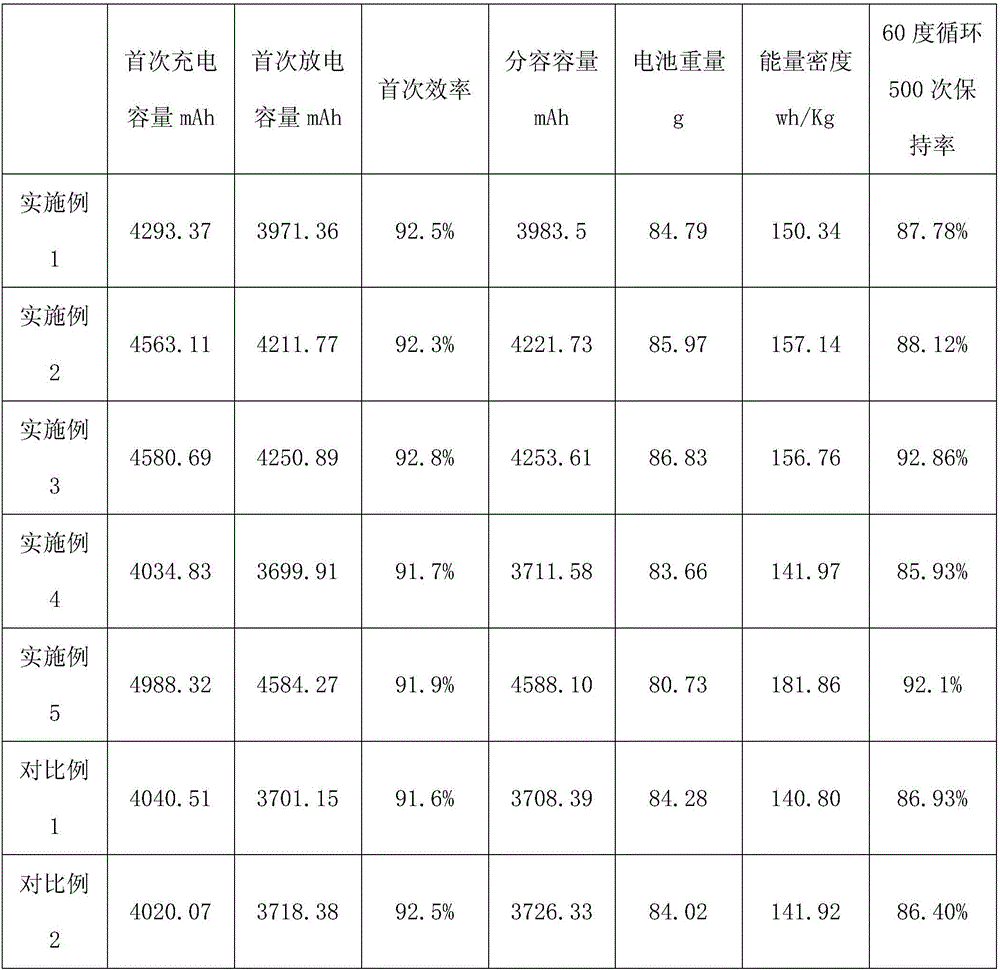

Examples

Embodiment 1

[0024] A method for improving the energy density and cycle life of lithium-ion batteries described in this embodiment uses lithium iron phosphate as the positive electrode active material, the gram specific capacity of lithium iron phosphate is 159mAh / g, and the initial efficiency is 99%; Graphite anode material, gram specific capacity 360mAh / g, initial efficiency 94%; LiCoO 2 As a supplementary active lithium material, LiCoO 2 It is added with the positive electrode active material during pre-sintering.

[0025] Among them, the production of the positive pole piece is: first configure 3wt% of the binder and 80-120wt% of the solvent methyl pyrrolidone into a glue, add 2wt% of the conductive agent to disperse well, and finally add 91.5wt% of the acid iron Lithium and 3.5 wt% LiCoO 2 , mix into a slurry, adjust the viscosity, and then coat the pole piece on a 0.016mm aluminum foil, with a double-sided density of 38mg / cm 2 , and rolled and cut to obtain the positive electrode ...

Embodiment 2

[0030] A method for improving the energy density and cycle life of lithium-ion batteries described in this embodiment uses lithium iron phosphate as the positive electrode active material, the gram specific capacity of lithium iron phosphate is 159mAh / g, and the initial efficiency is 98.5%; Graphite is the negative electrode active material, the gram specific capacity of artificial graphite is 360mAh / g, and the first efficiency is 94%; LiCoO 2 As a supplementary active lithium material, and LiCoO 2 It is added with the positive electrode active material during pre-sintering.

[0031] Among them, the production of the positive pole piece is: first configure 2wt% binder and 80-120wt% solvent methyl pyrrolidone to form a glue, add 1.5wt% conductive agent to disperse well, and finally add 89.5wt% phosphoric acid LiFe and 7wt% LiCoO 2 , mix into a slurry, adjust the viscosity, and coat the pole piece on a 0.016mm aluminum foil, with a double-sided density of 40mg / cm 2 , and roll...

Embodiment 3

[0036] This embodiment describes using lithium iron phosphate as the positive electrode active material, the gram specific capacity of lithium iron phosphate is 159mAh / g, and the initial efficiency is 99%; using artificial graphite as the negative electrode active material, the gram specific capacity of natural coated graphite is 355mAh / g, the first efficiency is 93%; with LiCoO 2 As a supplementary active lithium material, and LiCoO 2 It is added after premixing with the positive electrode active material.

[0037] Among them, the production of the positive electrode sheet is: first configure 2wt% of the binder and 100wt% of the solvent methyl pyrrolidone into a glue, add 1wt% of the conductive agent to disperse well, and finally add 87wt% of lithium iron phosphate and 10wt% % LiCoO 2 , mix into a slurry, adjust the viscosity, and coat a pole piece on a 0.016mm aluminum foil, with a double-sided density of 38mg / cm 2 , and rolled and cut to obtain the positive electrode sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com