Preparation method of chitosan-based medicine-carrying flexible sponge

A technology of chitosan and chitosan gel, which is applied in medical science, absorbent pads, bandages, etc., can solve the problems of poor stability of chitosan sponge, long process cycle, and inconvenient drug loading, and achieve convenient drug loading, The effect of short process cycle and improved safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

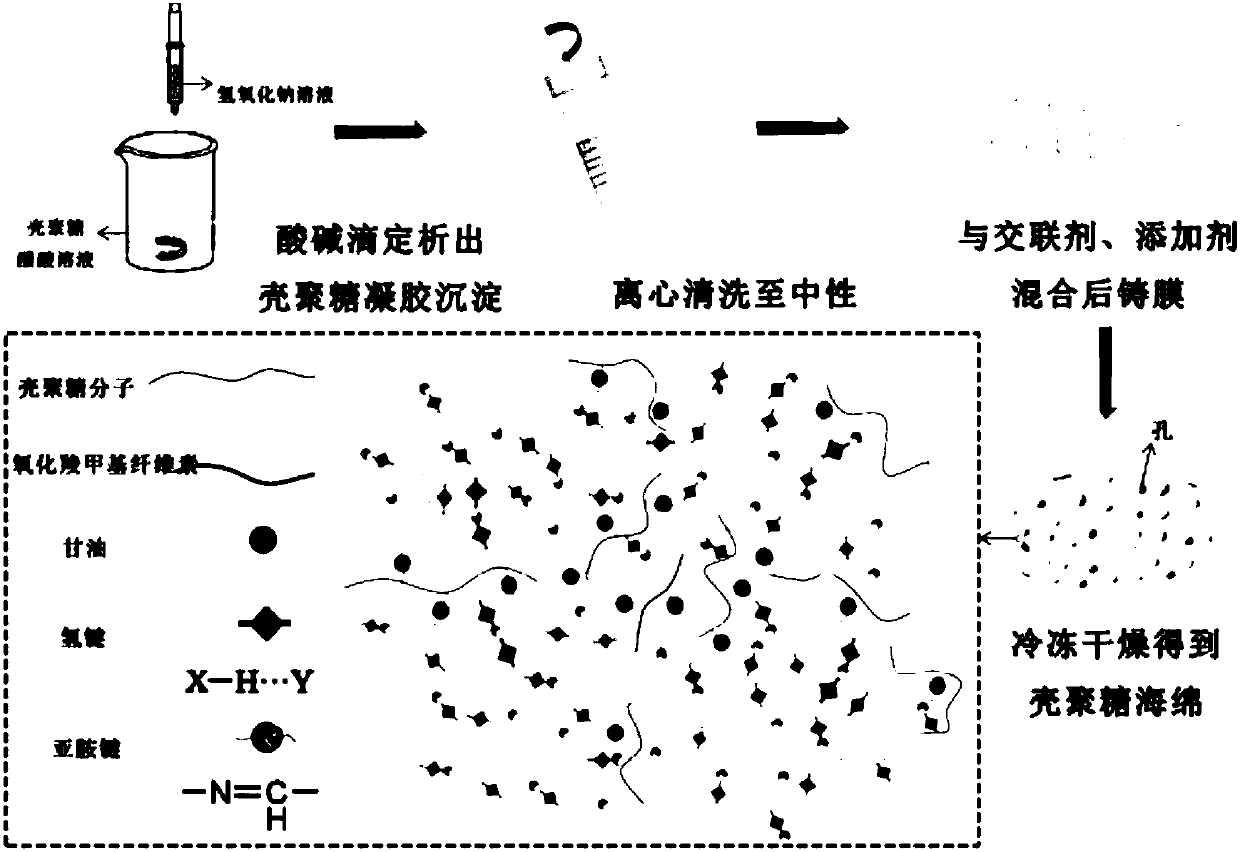

[0034] The preparation of chitosan-based drug-loaded flexible sponge, concrete steps are:

[0035] Step 1: Dissolve chitosan in 2% (v / v) acetic acid solution at room temperature, prepare 0.5% (w / v) chitosan acetic acid solution, dissolve sodium hydroxide in deionized water, and prepare 4% (w / v) solution.

[0036] Step 2: Under magnetic stirring, slowly add excess sodium hydroxide solution dropwise to the chitosan acetic acid solution until the white flocculent chitosan gel precipitates completely, and continues stirring for 30 minutes to fully disperse the precipitate.

[0037] Step 3: Wash the chitosan gel precipitate 4 times with high-speed deionized water, the centrifugation parameter is 70 rpm, and the centrifugation time is 5 minutes.

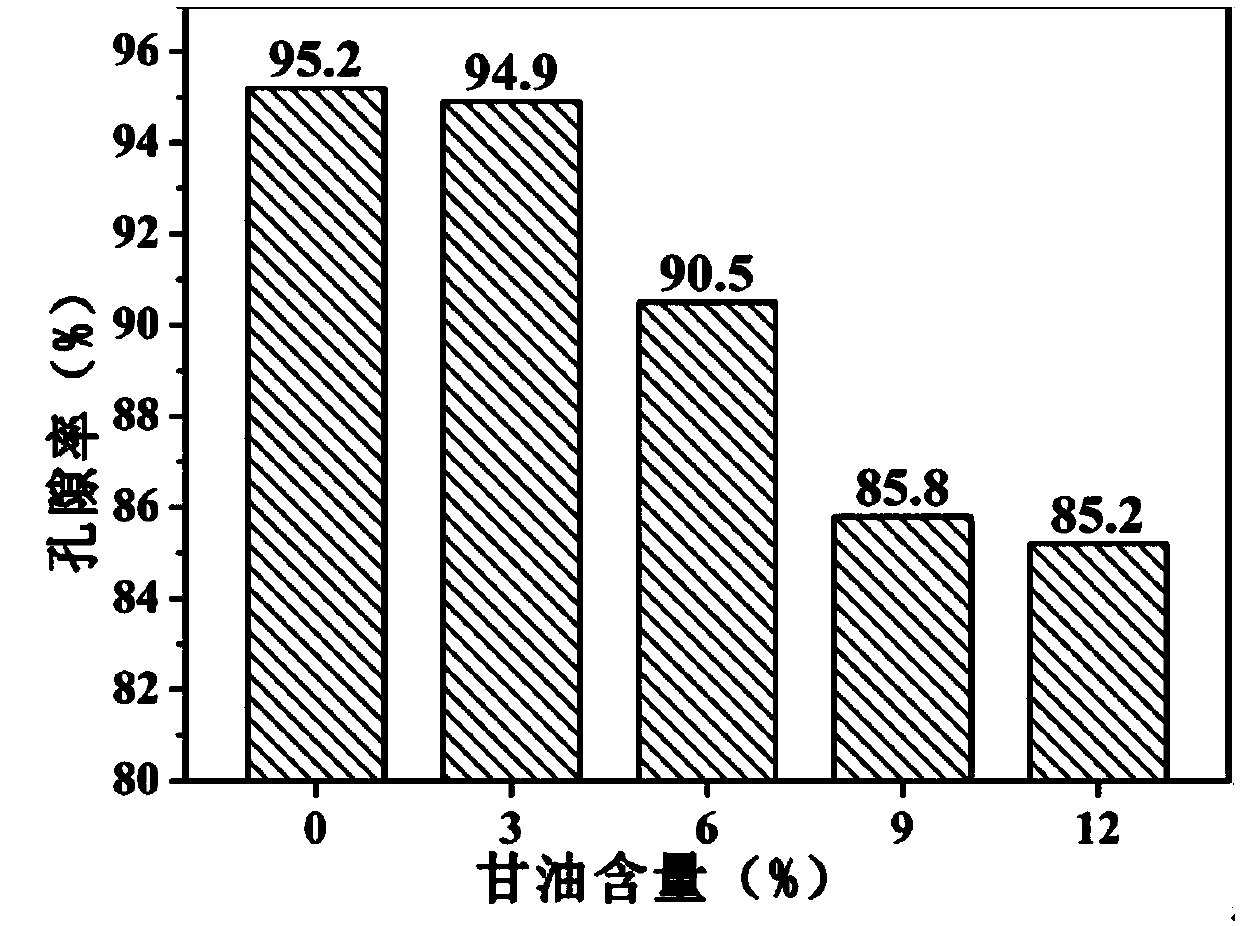

[0038] Step 4: According to the mass ratio of 8:1, mix the chitosan gel precipitation with 4% oxidized carboxymethyl cellulose solution, add 3% glycerol, and then press the drug loading ratio chitosan gel precipitation / hydrochloric acid ...

Embodiment 2

[0044] The preparation of chitosan-based drug-loaded flexible sponge, concrete steps are:

[0045] Step 1: Dissolve chitosan in 2% (v / v) acetic acid solution at room temperature, prepare 2.0% (w / v) chitosan acetic acid solution, dissolve sodium hydroxide in deionized water, and prepare 4% (w / v) solution.

[0046] Step 2: Under magnetic stirring, slowly add excess sodium hydroxide solution dropwise to the chitosan acetic acid solution until a white flocculent gel precipitate of chitosan is completely precipitated, and continue stirring for 30 minutes to fully disperse the precipitate.

[0047] Step 3: Wash the chitosan gel precipitate 4 times with high-speed deionized water, the centrifugation parameter is 70 rpm, and the centrifugation time is 5 minutes.

[0048] Step 4: Mix chitosan gel precipitation with oxidized carboxymethyl cellulose at a mass ratio of 1:1, add 3% glycerin, and then set the drug-loading ratio of chitosan gel precipitation / tetracycline hydrochloride to 15...

Embodiment 3

[0050] The preparation of chitosan-based drug-loaded flexible sponge, concrete steps are:

[0051] Step 1: Dissolve chitosan in 2% (v / v) acetic acid solution at room temperature, prepare 0.5% (w / v) chitosan acetic acid solution, dissolve sodium hydroxide in deionized water, and prepare 4% (w / v) solution.

[0052] Step 2: Under magnetic stirring, slowly add excess sodium hydroxide solution dropwise to the chitosan acetic acid solution until the white flocculent chitosan gel precipitates completely, and continues stirring for 30 minutes to fully disperse the precipitate;

[0053] Step 3: Wash the chitosan gel precipitate 4 times with high-speed deionized water, the centrifugation parameter is 70 rpm, and the centrifugation time is 5 minutes.

[0054] Step 4: Mix the chitosan gel precipitation with oxidized carboxymethyl cellulose at a mass ratio of 8:1, add 6% glycerin, and then set the drug-loading ratio of chitosan gel precipitation / tetracycline hydrochloride to 3000:1 Tetracy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com