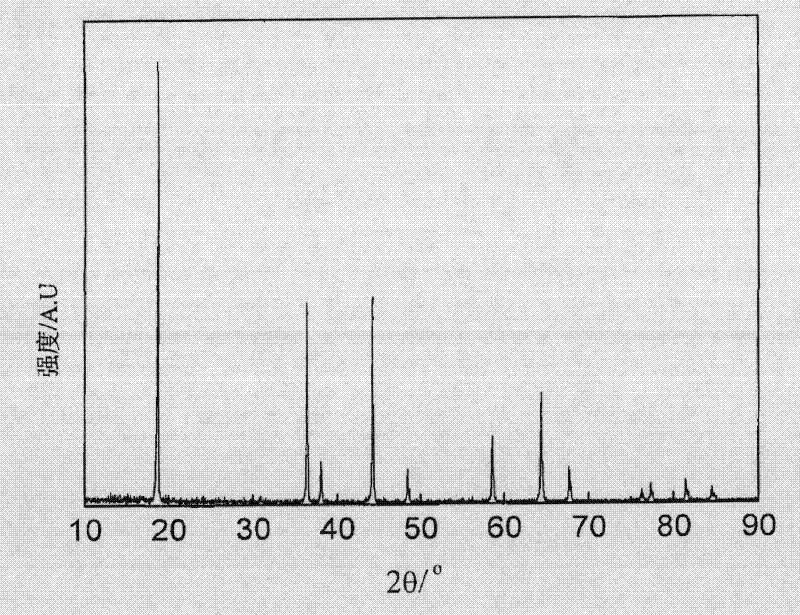

Cathode material for high voltage lithium battery

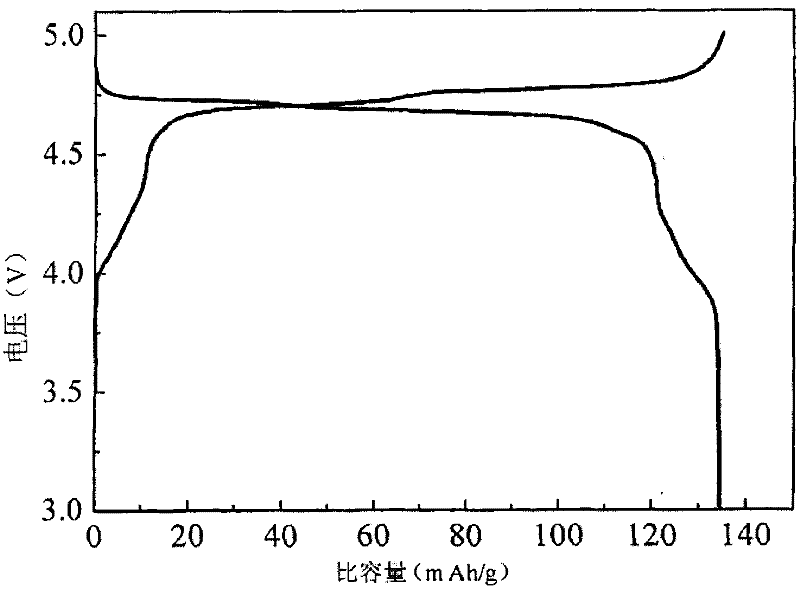

A cathode material, lithium battery technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of low initial discharge capacity, poor cycle stability, low reaction yield, etc., to achieve good electrochemical performance, cycle The effect of improved performance and simple synthesis method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

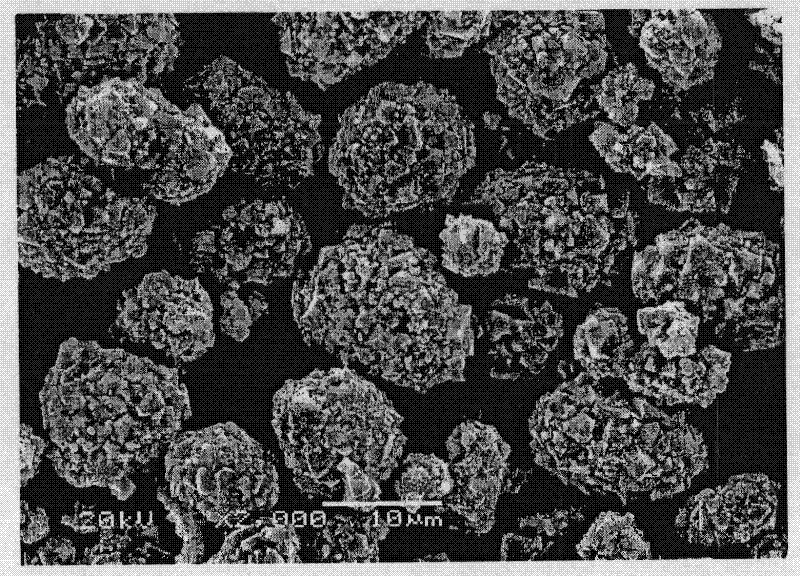

Embodiment 1

[0043] 4.5 mol of manganese sulfate, 1.38 mol of nickel sulfate, and 0.12 mol of copper sulfate were prepared into 3000 ml of soluble salt mixed solution, and 12.0 mol of sodium hydroxide and 280 ml of ammonia water were prepared into 3000 ml of mixed solvent. Add the above-mentioned soluble salt mixed solution and mixed solvent into a 10L reactor at the same speed of 3.0ml / min, control the reaction temperature to 50℃, pH value 9.0, and keep stirring until the reaction is over, and then stir after the reaction is over After 0.5 hours, the obtained black precipitate was separated, filtered, and dried to obtain a precursor. Mix 200g of the precursor with lithium hydroxide at a molar ratio of Li:(Mn+Ni+Cu) of 0.5, add anhydrous ethanol to mix, and dry; dry the dried product at 500℃ for 2 hours and then cool and grind Then, it was calcined at 950°C for 7 hours, cooled and ground, and passed through a 200-mesh sieve to obtain a black high-voltage lithium ion battery cathode material...

Embodiment 2

[0046] 3.0 mol of manganese chloride, 0.92 mol of nickel chloride, and 0.08 mol of magnesium chloride were prepared into 3000 ml of soluble salt mixed solution, and 8.0 mol of sodium hydroxide and 300 ml of ammonia water were prepared into 3000 ml of mixed solvent. Add the above-mentioned soluble salt mixed solution and mixed solvent at the same speed of 5.0ml / min into a 10L reactor, control the reaction temperature to 55℃, pH value 10.0, and keep stirring until the reaction is over, the black precipitate obtained Separate, wash with deionized water 3 times, filter and dry to obtain the precursor. Mix 200g of the precursor with lithium carbonate at a molar ratio of Li:(Mn+Ni+Mg) of 0.51, add deionized water, mix, and dry; dry the dried product at a constant temperature of 500°C for 2 hours and then cool and grind it. Then it was calcined at 850° C. for 10 hours, cooled and ground, and passed through a 200-mesh sieve to obtain a black high-voltage lithium ion battery cathode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com